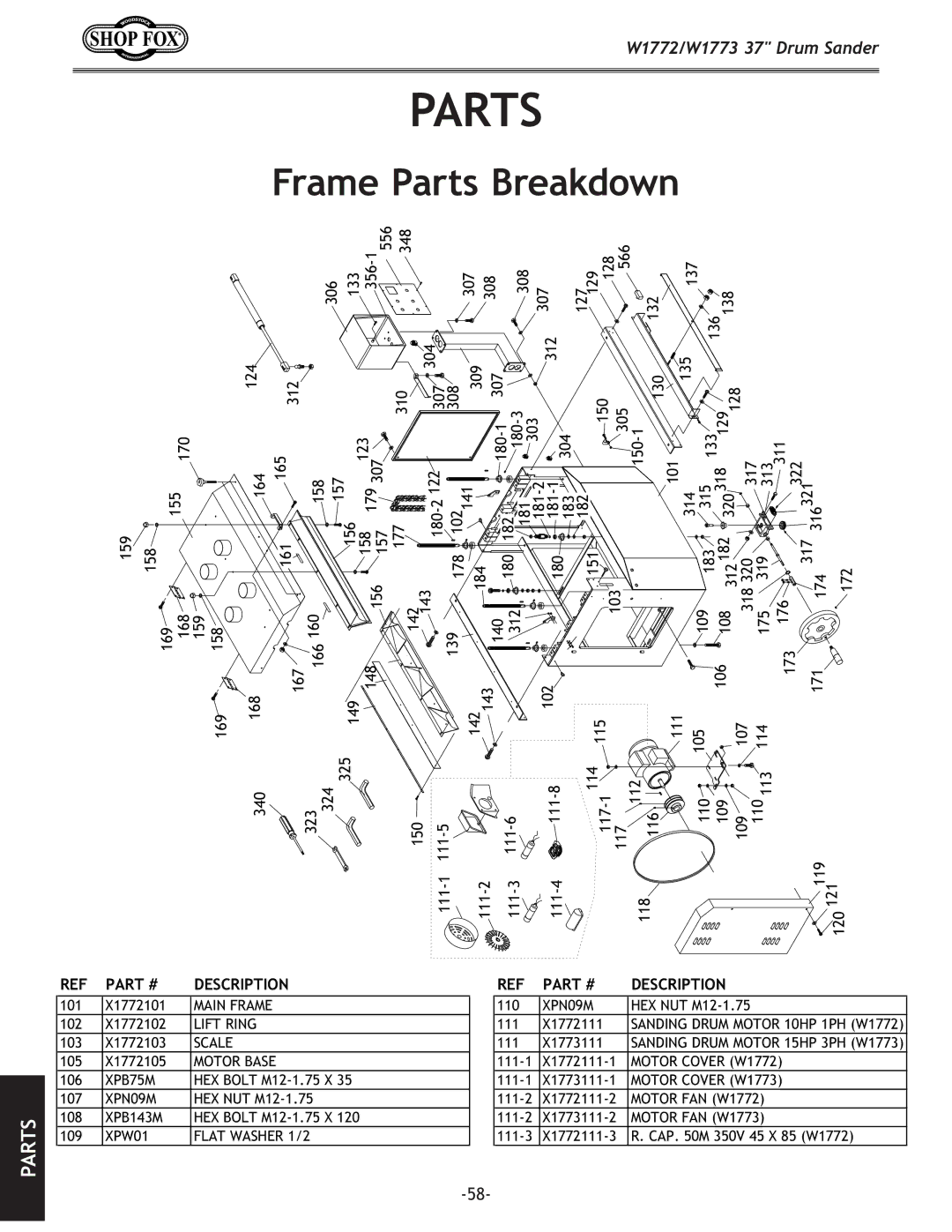

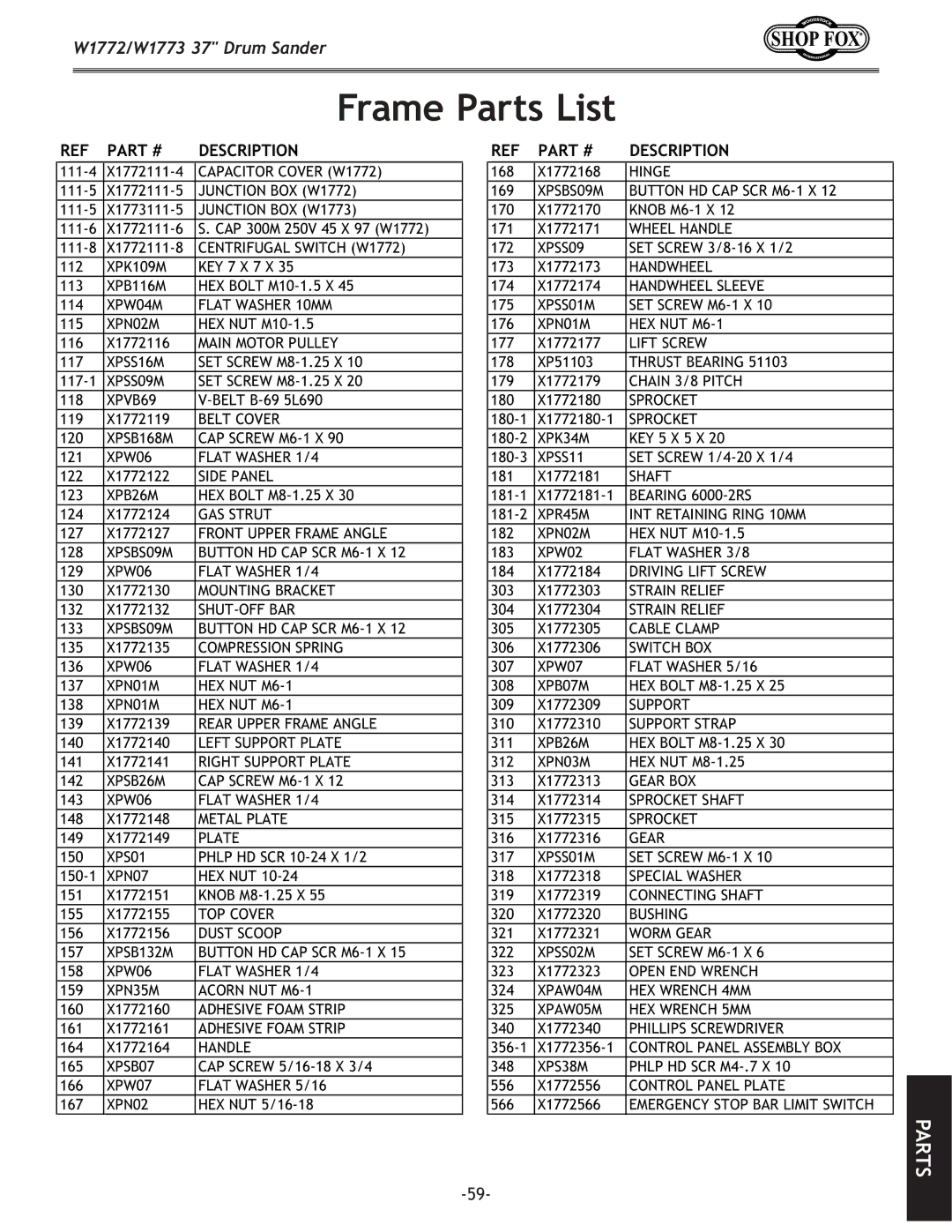

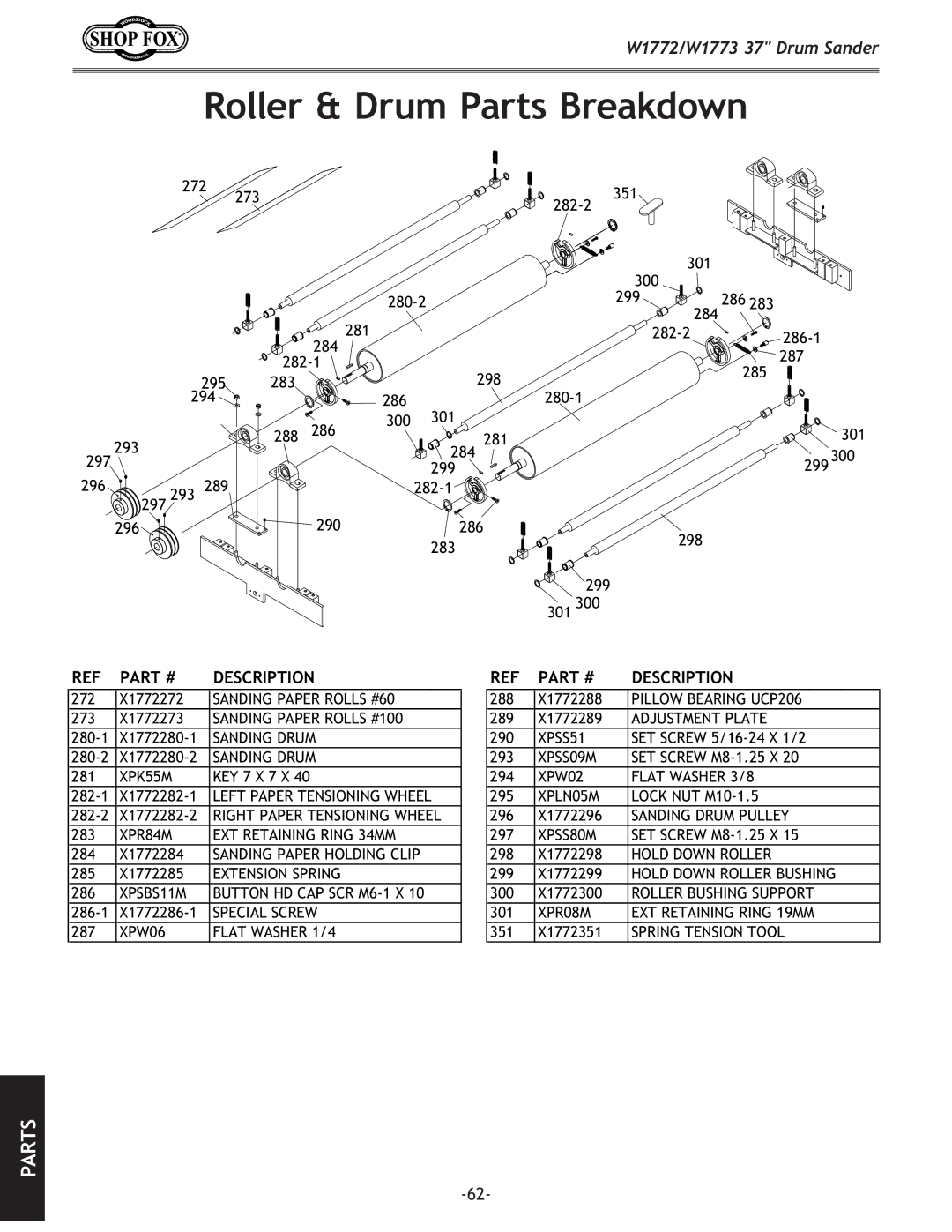

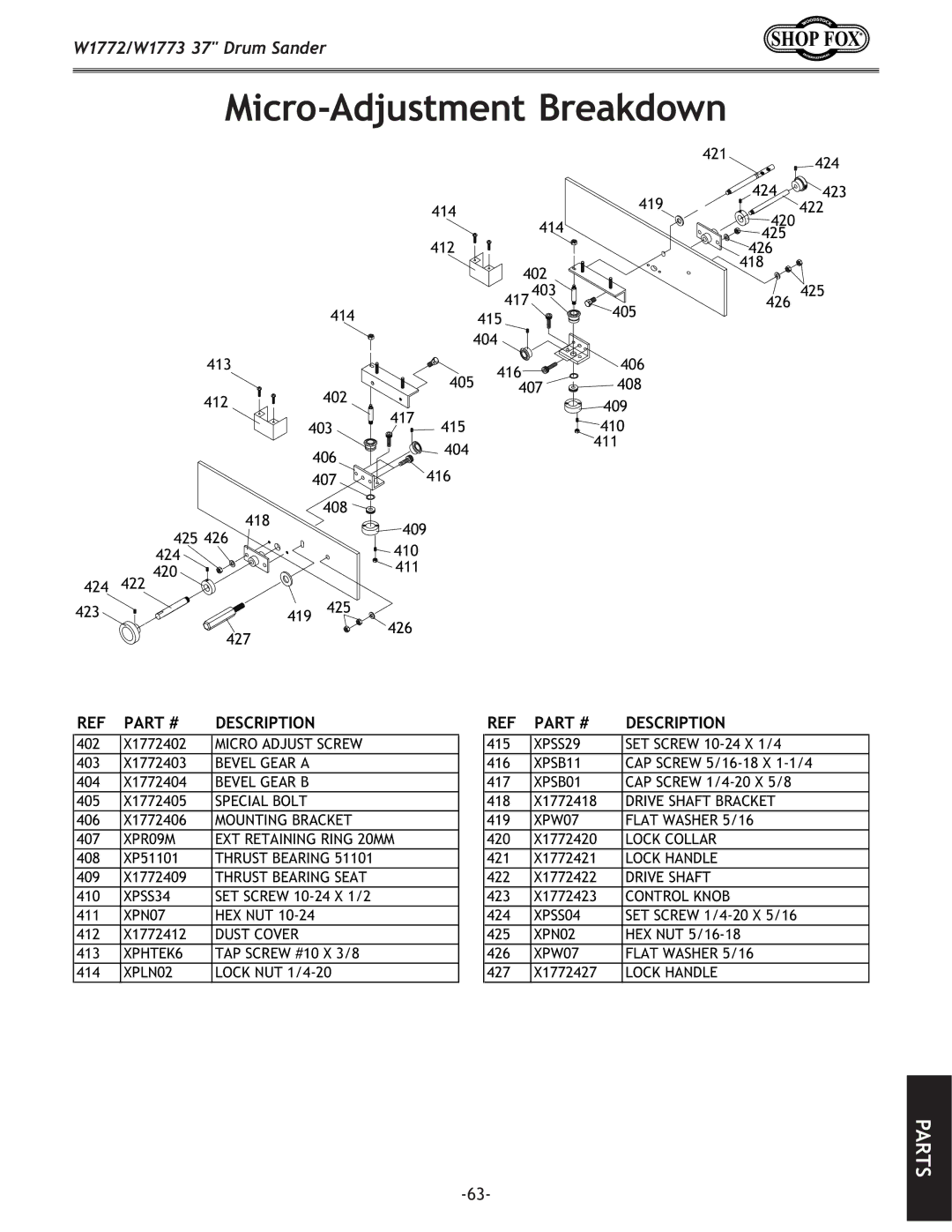

W1772/W1773 37" Drum Sander

SERVICE

Each tooth on the sprocket represents 0.006" of table elevation movement. For example, if the rear of the table was 0.006" low, rotate both rear table lift screws to the next sprocket tooth in the same chain position. You can easily rotate the sprockets from the top of the table lift screws with a flat head screwdriver.

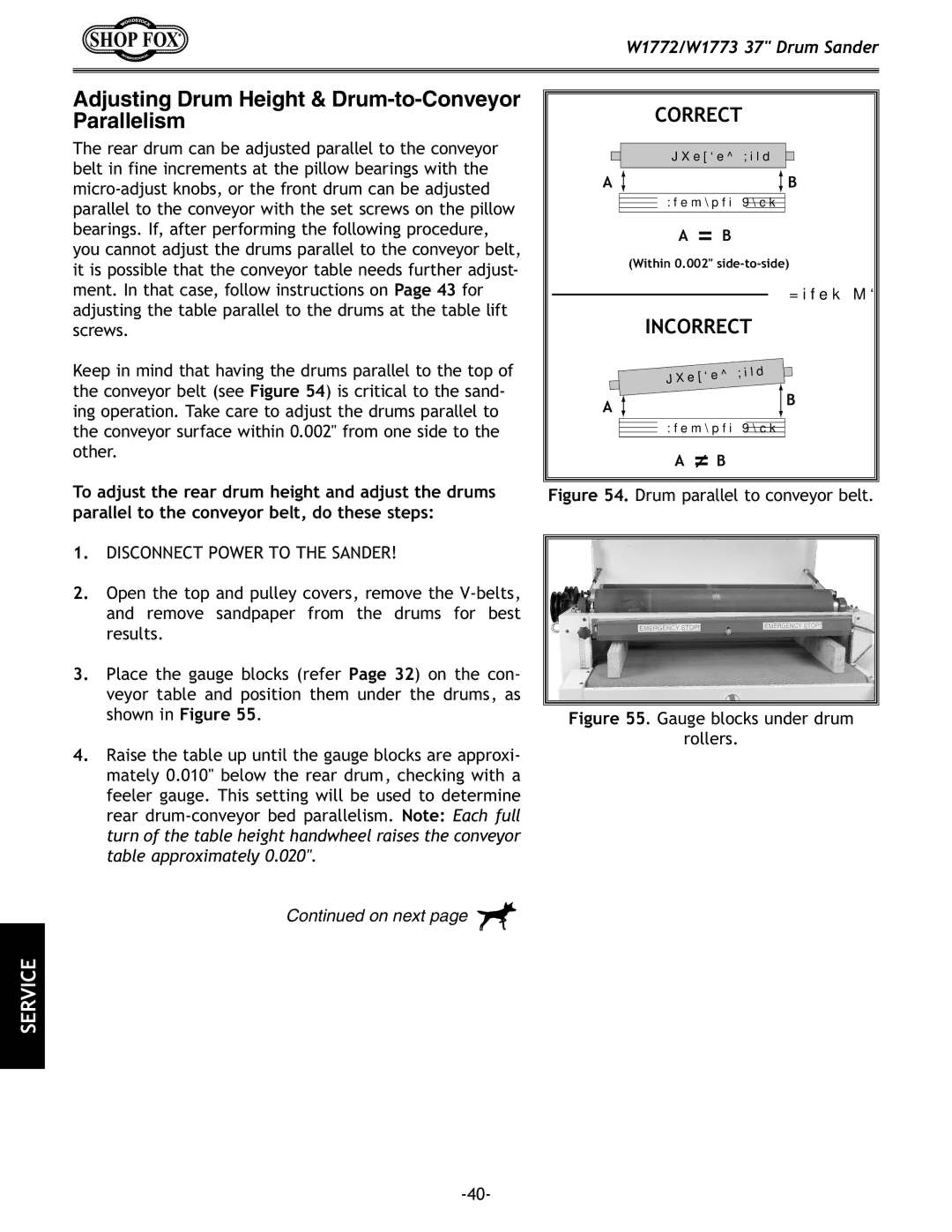

After adjusting the table lift screws, check to make sure the drums and conveyor are parallel within 0.002" from one side to the other. If they are not within this range, then additional fine adjustments should be made at the drum pillow bearings.

To adjust the table lift screws, do these steps:

1.DISCONNECT POWER TO THE SANDER!

2.Open the side cover.

3.Raise the table up to at least the 1" mark on the height scale.

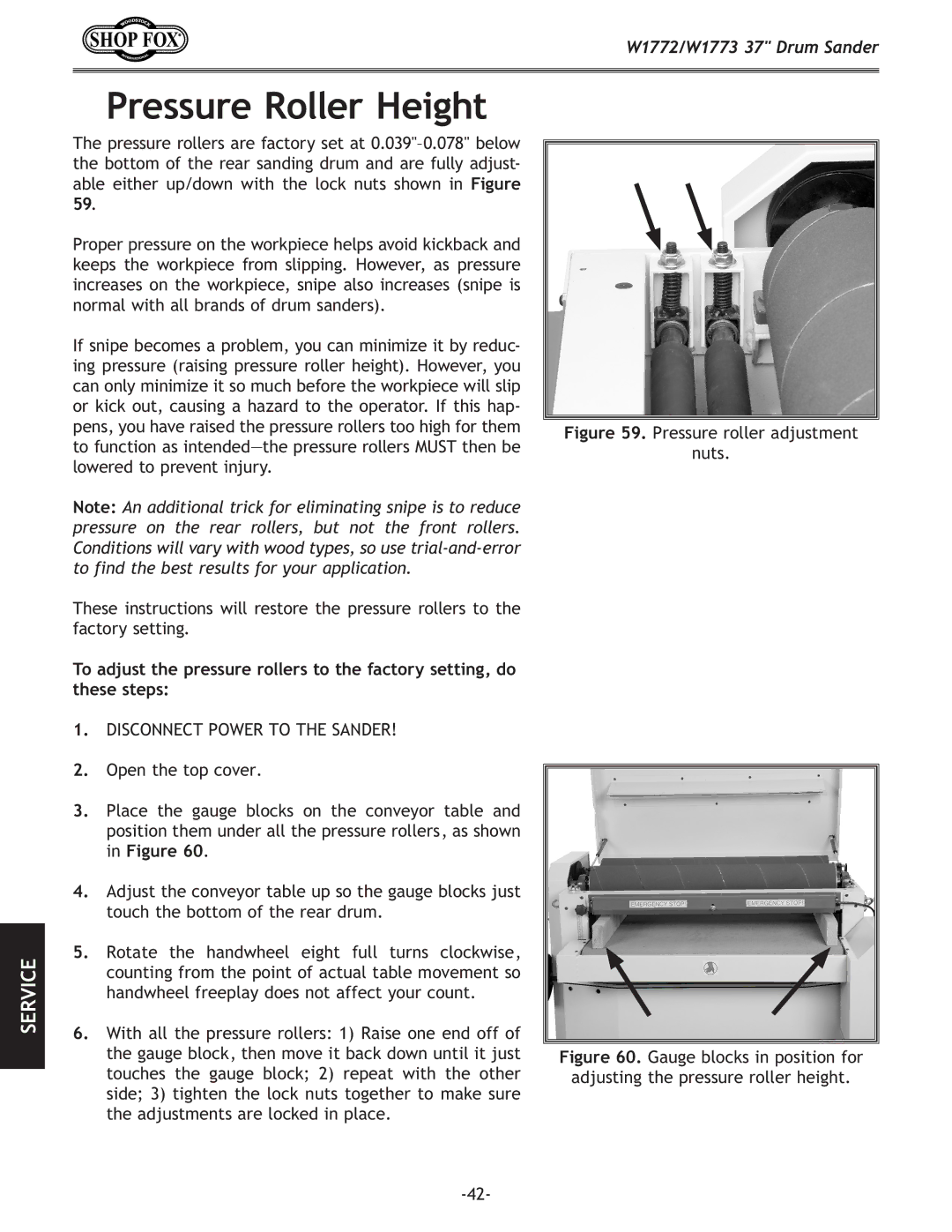

4.At the lift screw that needs to be adjusted, mark the end of a sprocket tooth and the chain hole where that tooth is meshed, as shown in Figure 63.

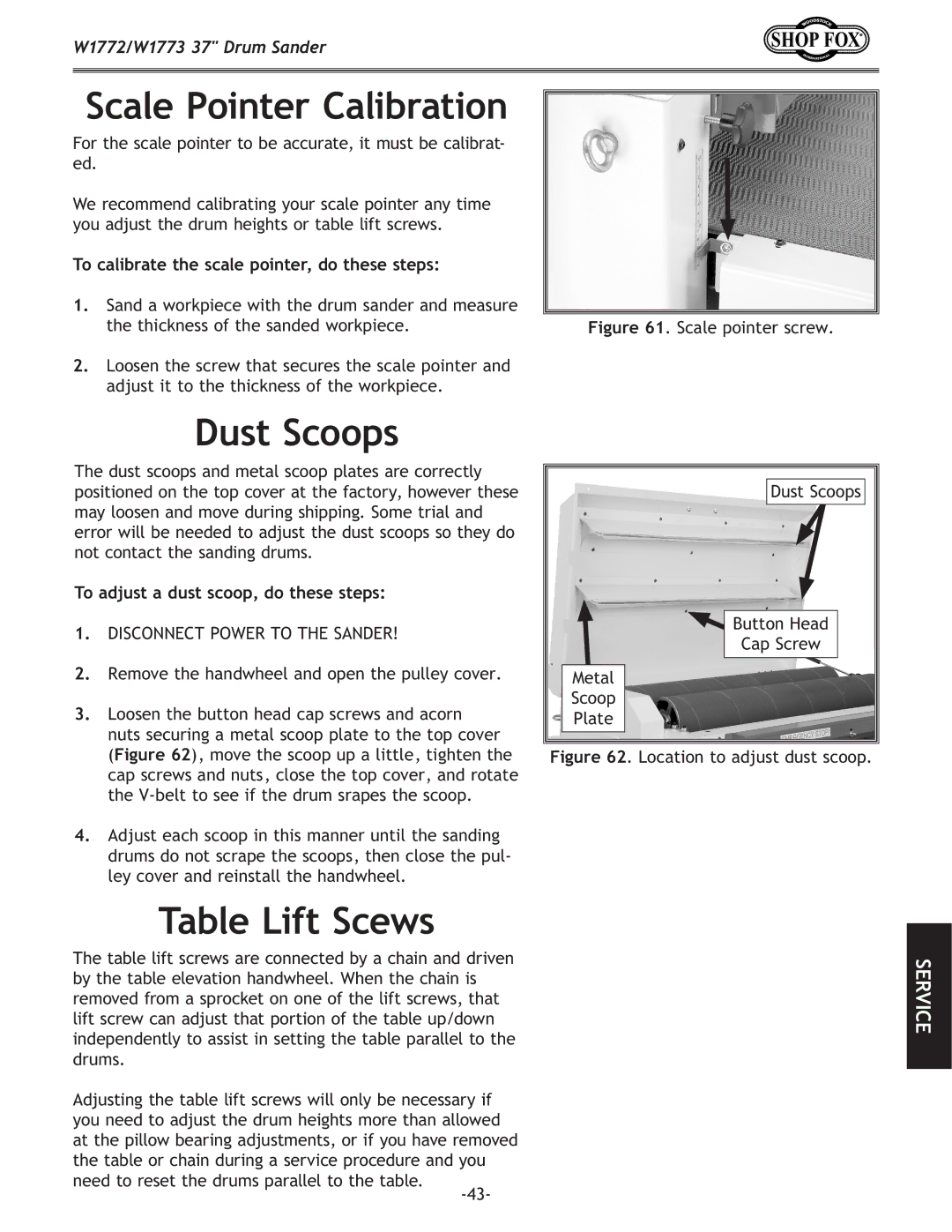

5.Using two 14mm wrenches, loosen the adjustable idler roller (Figure 64).

6.Carefully move the chain off of only the marked sprocket.

7.Keep track of the marked chain hole and rotate the sprocket the necessary number of teeth away from the marked one to meet the difference in height needed.

8.Fit the chain back over the sprocket, making sure the new sprocket tooth is inserted into the marked chain hole.

9.

10.Repeat Steps

11.Follow instructions in Drum Adjustments (Refer to Page 38) for adjusting the drums parallel to the con- veyor within 0.002"