W1772/W1773 37" Drum Sander

Each pulley can be adjusted by loosening the set screw that secures the pulley to the shaft, sliding the pulley in/ out, and retightening the set screw to lock the pulley in place.

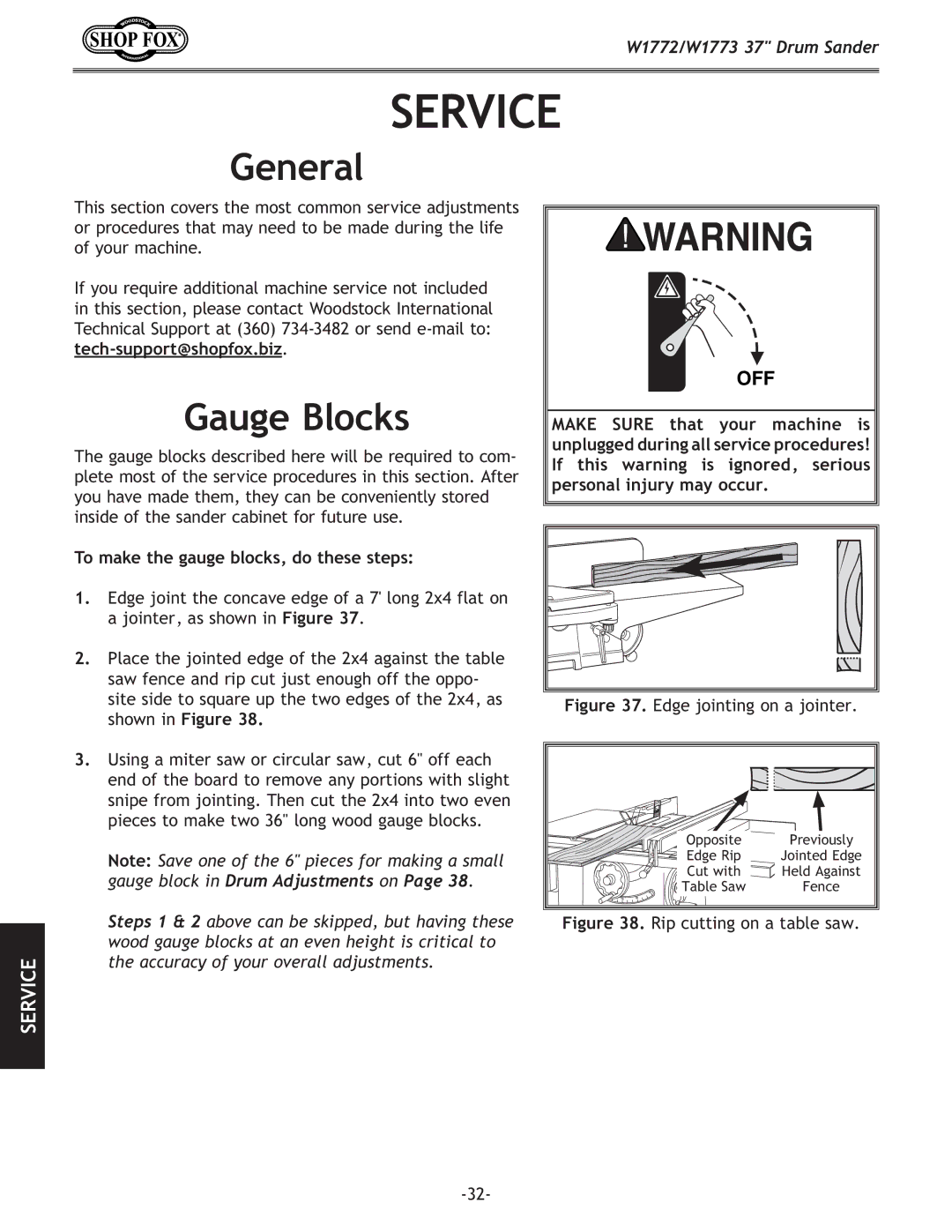

To align the pulleys, do these steps:

1.DISCONNECT POWER TO THE SANDER!

2.Remove the table height handwheel, open the pulley cover, and remove the

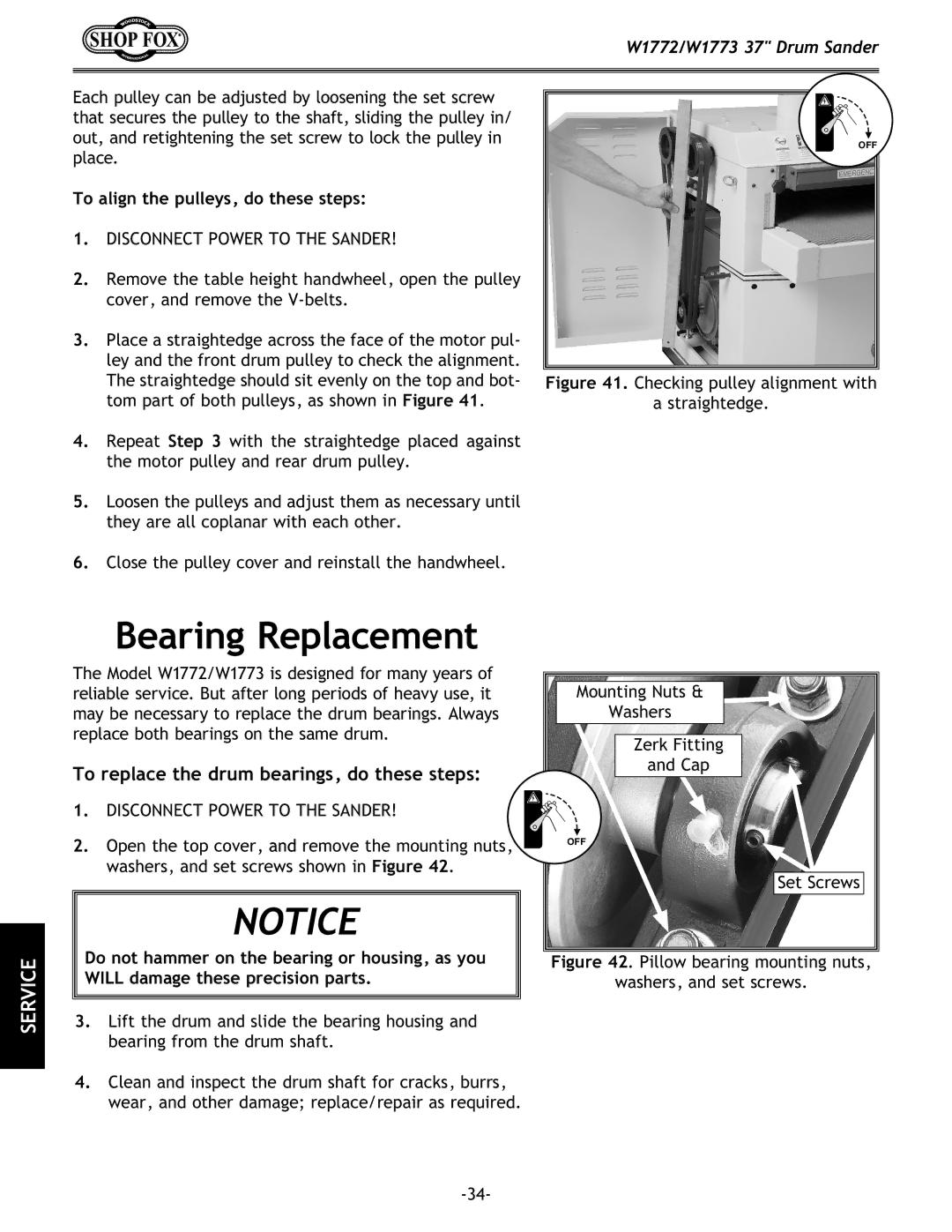

3.Place a straightedge across the face of the motor pul- ley and the front drum pulley to check the alignment. The straightedge should sit evenly on the top and bot- tom part of both pulleys, as shown in Figure 41.

4.Repeat Step 3 with the straightedge placed against the motor pulley and rear drum pulley.

5.Loosen the pulleys and adjust them as necessary until they are all coplanar with each other.

OFF

Figure 41. Checking pulley alignment with

a straightedge.

6.Close the pulley cover and reinstall the handwheel.

SERVICE

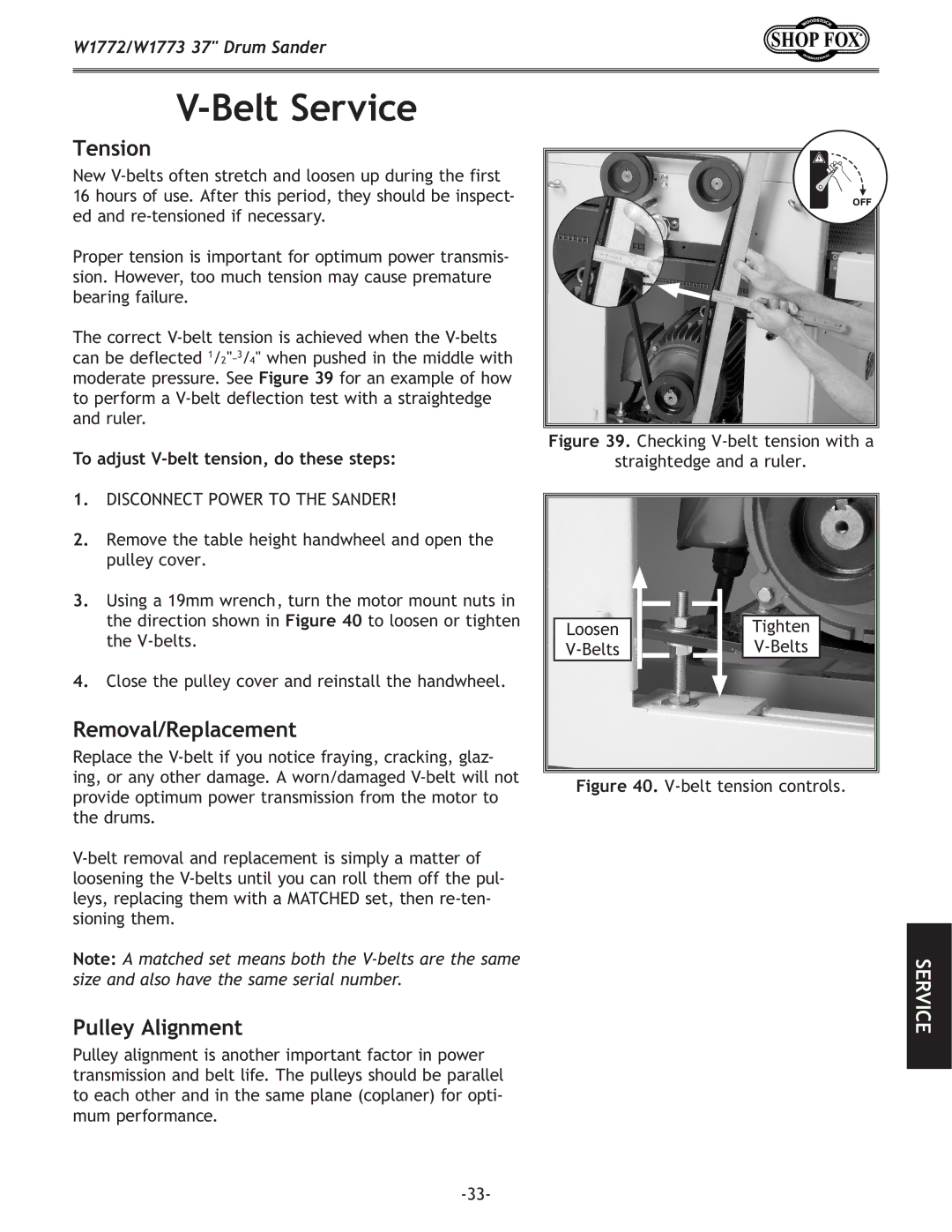

Bearing Replacement

The Model W1772/W1773 is designed for many years of reliable service. But after long periods of heavy use, it may be necessary to replace the drum bearings. Always replace both bearings on the same drum.

To replace the drum bearings, do these steps:

1. DISCONNECT POWER TO THE SANDER!

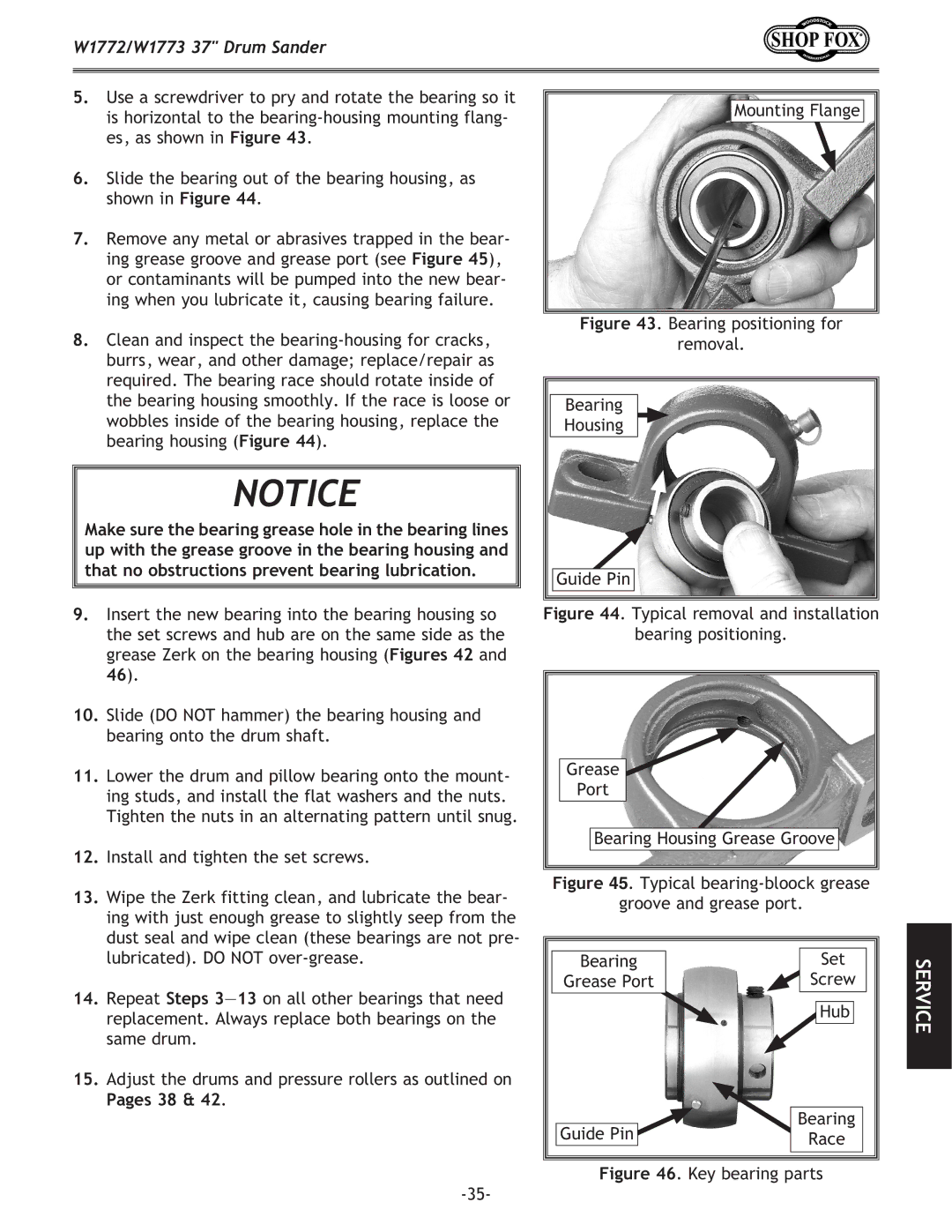

2.Open the top cover, and remove the mounting nuts, washers, and set screws shown in Figure 42.

NOTICE

Do not hammer on the bearing or housing, as you WILL damage these precision parts.

3.Lift the drum and slide the bearing housing and bearing from the drum shaft.

4.Clean and inspect the drum shaft for cracks, burrs, wear, and other damage; replace/repair as required.

Mounting Nuts & |

Washers |

Zerk Fitting |

and Cap |

OFF |

Set Screws |

Figure 42. Pillow bearing mounting nuts, |

washers, and set screws. |