r1 Readout of the setup data from EEPROM

(Data in EEPROM contents, which have been changed at the local site, are read out together with data in EEPROM set at shipment from the factory.)

1.Push SET , ![]() , and

, and ![]() buttons of the remote controller at the same time for 4 seconds or more. 1 (Corresponded with No. in Remote controller)

buttons of the remote controller at the same time for 4 seconds or more. 1 (Corresponded with No. in Remote controller)

When group operation, the master indoor unit address is displayed at the first time. In this time, the item code (DN) 10 is displayed. The fan of the selected indoor unit operates and the flap starts swinging if any.

2.Every pushing ![]() button, the indoor unit address in the group are displayed successively. 2 Specify the indoor unit No. to be replaced.

button, the indoor unit address in the group are displayed successively. 2 Specify the indoor unit No. to be replaced.

3.Using the set temperature ![]() /

/ ![]() buttons, the item code (DN) can be moved up and down one by one.3

buttons, the item code (DN) can be moved up and down one by one.3

4.First change the item code (DN) from 10 to 01. (Setting of filter sign lighting time) Make a note of the set data displayed in this time.

5.Next change the item code (DN) using the set temperature ![]() /

/ ![]() buttons. Also make a note of the set data.

buttons. Also make a note of the set data.

6.Repeat item 5. and make a note of the important set data as shown in the later table (Ex.).

• 01 to 9F are provided in the item code (DN). On the way of operation, DN No. may come out.

7.After finishing making a note, push ![]() button to return the status to usual stop status. 6 (Approx. 1 minute is required to start handling of the remote controller.)

button to return the status to usual stop status. 6 (Approx. 1 minute is required to start handling of the remote controller.)

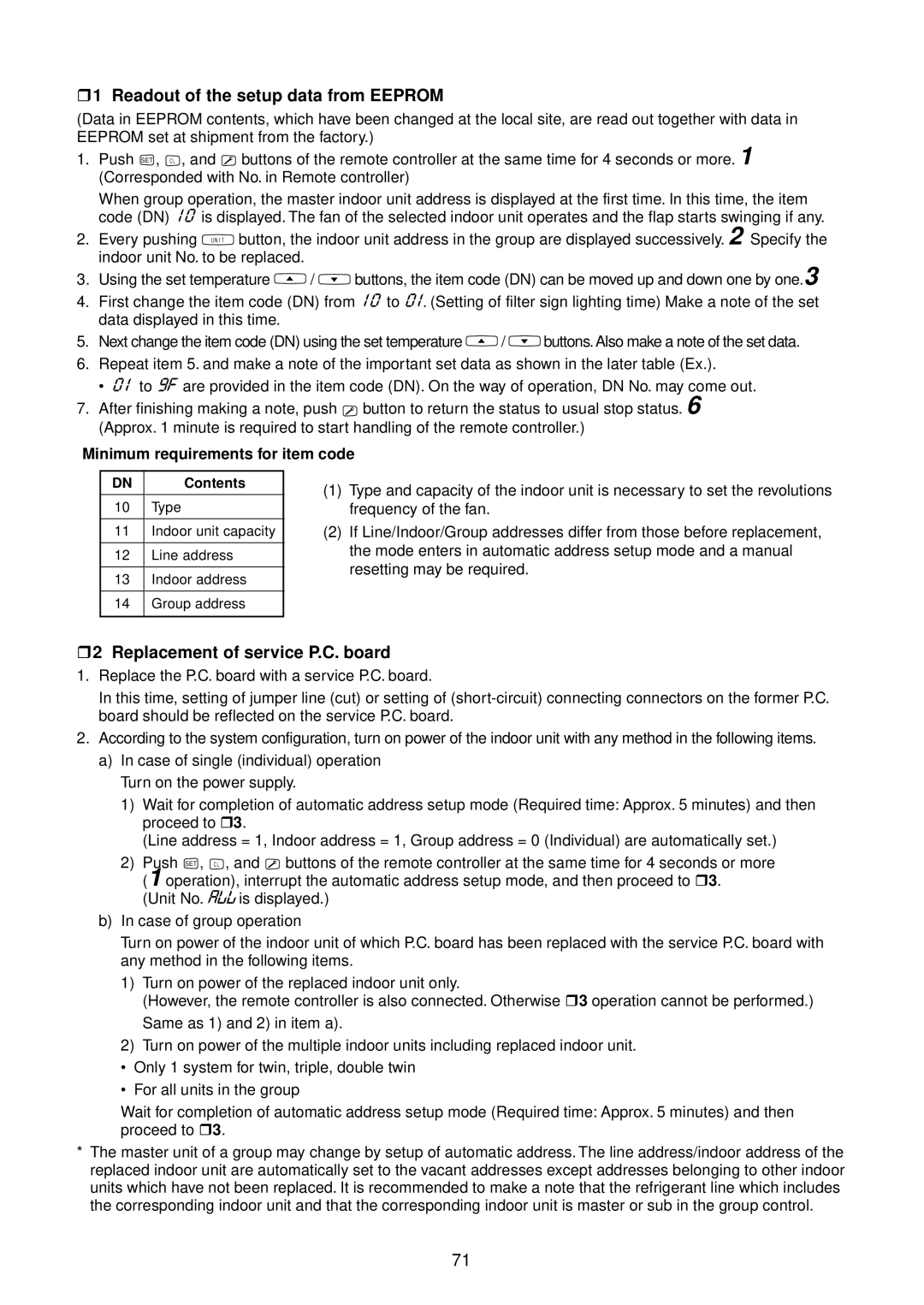

Minimum requirements for item code

DN | Contents |

|

|

10 | Type |

|

|

11 | Indoor unit capacity |

|

|

12 | Line address |

|

|

13 | Indoor address |

|

|

14 | Group address |

|

|

(1)Type and capacity of the indoor unit is necessary to set the revolutions frequency of the fan.

(2)If Line/Indoor/Group addresses differ from those before replacement, the mode enters in automatic address setup mode and a manual resetting may be required.

r2 Replacement of service P.C. board

1.Replace the P.C. board with a service P.C. board.

In this time, setting of jumper line (cut) or setting of

2.According to the system configuration, turn on power of the indoor unit with any method in the following items.

a)In case of single (individual) operation Turn on the power supply.

1)Wait for completion of automatic address setup mode (Required time: Approx. 5 minutes) and then proceed to r3.

(Line address = 1, Indoor address = 1, Group address = 0 (Individual) are automatically set.)

2)Push SET , ![]() , and

, and ![]() buttons of the remote controller at the same time for 4 seconds or more (1 operation), interrupt the automatic address setup mode, and then proceed to r3.

buttons of the remote controller at the same time for 4 seconds or more (1 operation), interrupt the automatic address setup mode, and then proceed to r3.

(Unit No. ALL is displayed.)

b)In case of group operation

Turn on power of the indoor unit of which P.C. board has been replaced with the service P.C. board with any method in the following items.

1)Turn on power of the replaced indoor unit only.

(However, the remote controller is also connected. Otherwise r3 operation cannot be performed.) Same as 1) and 2) in item a).

2)Turn on power of the multiple indoor units including replaced indoor unit.

•Only 1 system for twin, triple, double twin

•For all units in the group

Wait for completion of automatic address setup mode (Required time: Approx. 5 minutes) and then proceed to r3.

*The master unit of a group may change by setup of automatic address. The line address/indoor address of the replaced indoor unit are automatically set to the vacant addresses except addresses belonging to other indoor units which have not been replaced. It is recommended to make a note that the refrigerant line which includes the corresponding indoor unit and that the corresponding indoor unit is master or sub in the group control.

71