Split Type

Contents

Specifications

Indoor Unit

Concealed Duct Type

RAV-SM1101BT-E RAV-SM1401BT-E

RAV-SM560AT-E RAV-SM800AT-E

Outdoor Unit

RAV-SM1100AT-E RAV-SM1400AT-E

Cooling Heating

Operation Characteristic Curve

Capacity Variation Ratio According to Temperature

Cooling

Heating

AIR Ducting Work

Static Pressure Characteristics of Each Model

RAV-SM1101BT-E Round duct

RAV-SM561BT-E / SM801BT-E / SM1101BT-E / SM1401BT-E

Dimension

Construction Views External Views

Indoor Unit Concealed Duct Type

RAV-SM560AT-E

RAV-SM800AT-E

RAV-SM1100AT-E / SM1400AT-E

Outdoor unit

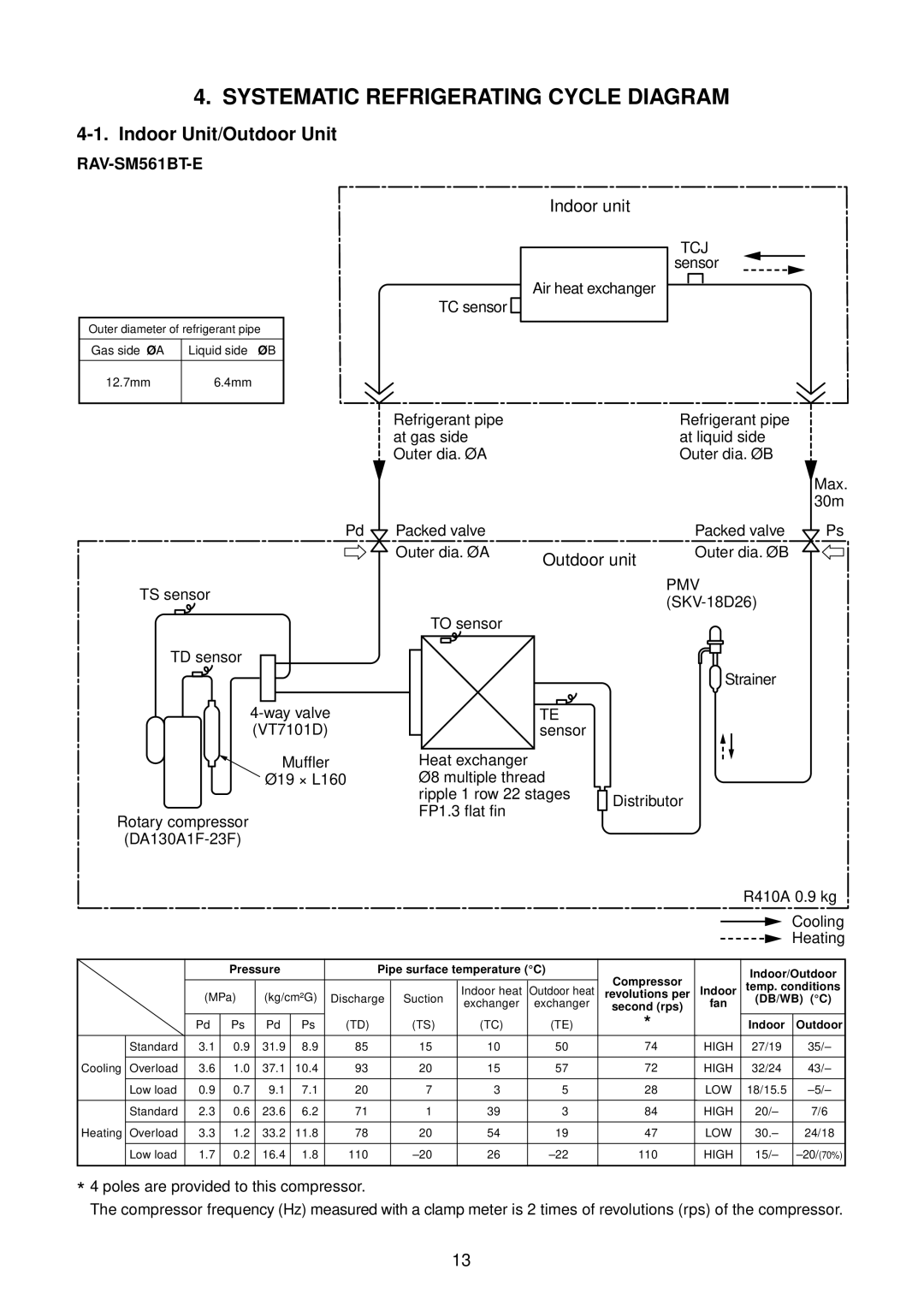

Systematic Refrigerating Cycle Diagram

Indoor Unit/Outdoor Unit

Indoor unit

RAV-SM801BT-E

RAV-SM1001BT-E

Second rps Fan Indoor Outdoor

Strainer

Wiring Diagram

Color

Identification

MCC-813

Color Identification

For P.C. Board

MCC-1359

MCC-1398

MCC-1438

Parts name Type Specifications

Specifications of Electrical Parts

RAV-SM1100AT-E

Piping Materials and Joints Used

Safety During Installation/Servicing

Refrigerant Piping Installation

Refrigerant R410A

Nominal diameter

Processing of Piping Materials

1 Thicknesses of annealed copper pipes Thickness mm

Outer diameter mm R410A R22

Diameter

Flare tool for Conventional flare tool

R410A clutch type Clutch type Wing nut type

R22 clutch type Clutch type Wing nut type

Wrenches available on the market

Nm kgfcm

Tools

Required Tools

General tools Conventional tools can be used

Recharging of Refrigerant

1 Configuration of refrigerant charging

Brazing of Pipes

Materials for Brazing

Flux

Never use gas other than Nitrogen gas

Brazing

Main Sub master remote controller Weekly timer

Indoor Unit Control

Indoor Control Circuit

Control Specifications

Outline of specifications Remarks

Remote controller Outline of control Command

Operation

Heating Auto

Heat

Control temp C

Operation Prohibited

Case of wired remote controller

Last push priority

Center

Ta˚C Normal control

RAV-SM561BT-E / SM801BT-E / SM1101BT

Indoor Print Circuit Board

MCC-1402

SM1401BT-E

Function Connector Pin Specifications Remarks

Indoor P.C. Board Optional Connector Specifications

Pulse Modulating Valve PMV control

Discharge temperature release control

Outdoor Control

Outline of Main Controls

MAX

Heating operation

Outdoor fan control Object SM560

Allocations of fan tap revolutions

Cooling operation

Current release value shift control

Short intermittent operation preventive control

High-pressure suppression TE control For SM800

Over-current preventive control

Start of heating operation

Defrost control

Outdoor Controls

Print Circuit Board

MCC-813 RAV-SM560AT-E Viewed from parts of P.C board

MCC-1398 RAV-SM800AT-E / SM1100AT-E / SM1400AT-E

Before troubleshooting

Troubleshooting

Summary of Troubleshooting

Wired remote controller type

Error mode detected by indoor unit

Check Code List

Diagnostic function Cause of operation

Error mode detected by outdoor unit

Timer Ready Wired remote Controller Check code

Error mode detected by remote controller or network adapter

Ipdu side

Error Mode Detected by LED on Outdoor P.C. Board

SW800 LED display in bit 1, bit 2, bit 3, bit 4 OFF

CDB side

SW800 LED display in bit 1, bit 2, bit 3 OFF

Check code

Type a

New Check Code/Present Check Code Central Control Side

Troubleshooting Procedure for Each Check Code

E01 error/*99 error

E09 error/*99 error

E04 error/04 error

L09 error/46 error

E10 error/CF error

E18 error/97 error *99 error

E08, L03, L07, L08 error/ *96 error 99 error

L20 error/98 error

L30 error/B6 error

B7 error Central controller

F10 error 0C error

P10 error/Ob error

P12 error/11 error

P22 error/1A error

Single phase

RAV-SM1100AT-E, SM1400AT-E

F02 error/0d error

P19 error/08 error

P26 error/14 error

F01 error/0F error

H03 error/17 error

P29 error/16 error

F06 error/18 error

F04 error/19 error

F08 error/1b error

H02 error/1d error

L29 error/1C error

H01 error/1F error

P03 error/1E error

P04 error/21 error

Error Central controller

E03 error Master indoor unit

F29 error / 12 error

P31 error Sub indoor unit

TD sensor Caracteristics-4

TA sensor TC, TCJ sensor Caracteristics-2 Caracteristics-1

Caracteristics-3

20 TE, TO, TS sensor

Case

Replacement of Service Indoor P.C. Board

Minimum requirements for item code

R1 Readout of the setup data from Eeprom

R2 Replacement of service P.C. board

Contents

R3 Writing of the setup contents to Eeprom

Memorandum for setup contents Item code table Example

Type Item code

Indoor unit capacity Item code

Wired remote controller

Setup AT Local Site and Others

Test Run Setup on Remote Controller

Setup to Select Function

Description At shipment

Item No. DN table Selection of function

Cabling and Setting of Remote Controller Control

Setup method

Operation

Monitor Function of Remote Controller Switch

Contents

Procedure

System example

Calling of error history

Group control operation

Requirement

Network Adapter

Microcomputer Block Diagram

Network Address Setup Switch SW01

LED Display Specification

Network cable connection

Communication Cable Specifications

Communication circuit Communication cable specifications

Cable Connection

Procedure Set the network address while the unit stops

How to Set an Address Number

How to set from the remote controller at indoor unit side

How to set by the switch on the network adapter P.C. board

Requirement in Service

Network address No. setup table SW01

Address No

Contents Remarks

Address Setup

Address Setup

Address setup procedure

Automatic address example from unset address No miscabling

Address Setup & Group Control

System configuration

Only turning on source power supply Automatic completion

Setup completes Status returns to the usual stop status

Manual setting from remote controller

Push button if the unit stops

To know the position of indoor unit body by address

Push and buttons simultaneously for 4 seconds or more

Detachments

Part name Procedure Remarks

No. Part name Procedure Remarks

† Drain pump Remove the drain pan and float switch

Attachment

Detachment

Part name

Procedure Remarks

Requirement

Part name Procedure

Connection with the power terminal

Take off fixed screw for the valve mounting

‡ Compressor Perform works of items 1 ‚, ƒ, „, …

Fan guard

Remove the upper cabinet

Discharge port cabinet for the heat ex

Requirement

100

101

102

103

104

Product

105

106

107

108

109

110

Case of RAV-SM1400AT-E

111

Case of RAV-SM1100AT-E

Be sure to mount the propeller fan

112

113

Location

Exploded Views and Parts List

114

Part Description

115

904 901, 902, 903 35, 36, 37

RAV-SM1001BT-E / SM1401BT-E

116

RAV-SM561BT-E / SM801BT-E / SM1001BT-E / SM1401BT-E

117

118

Inverter

119

702 TE Sensor TS Sensor To Sensor TD Sensor 701 705 703 704

120

21,22 16,17

121

706

122

Inverter 26,27 23,24 28,29

123

TH Sensor

![]()