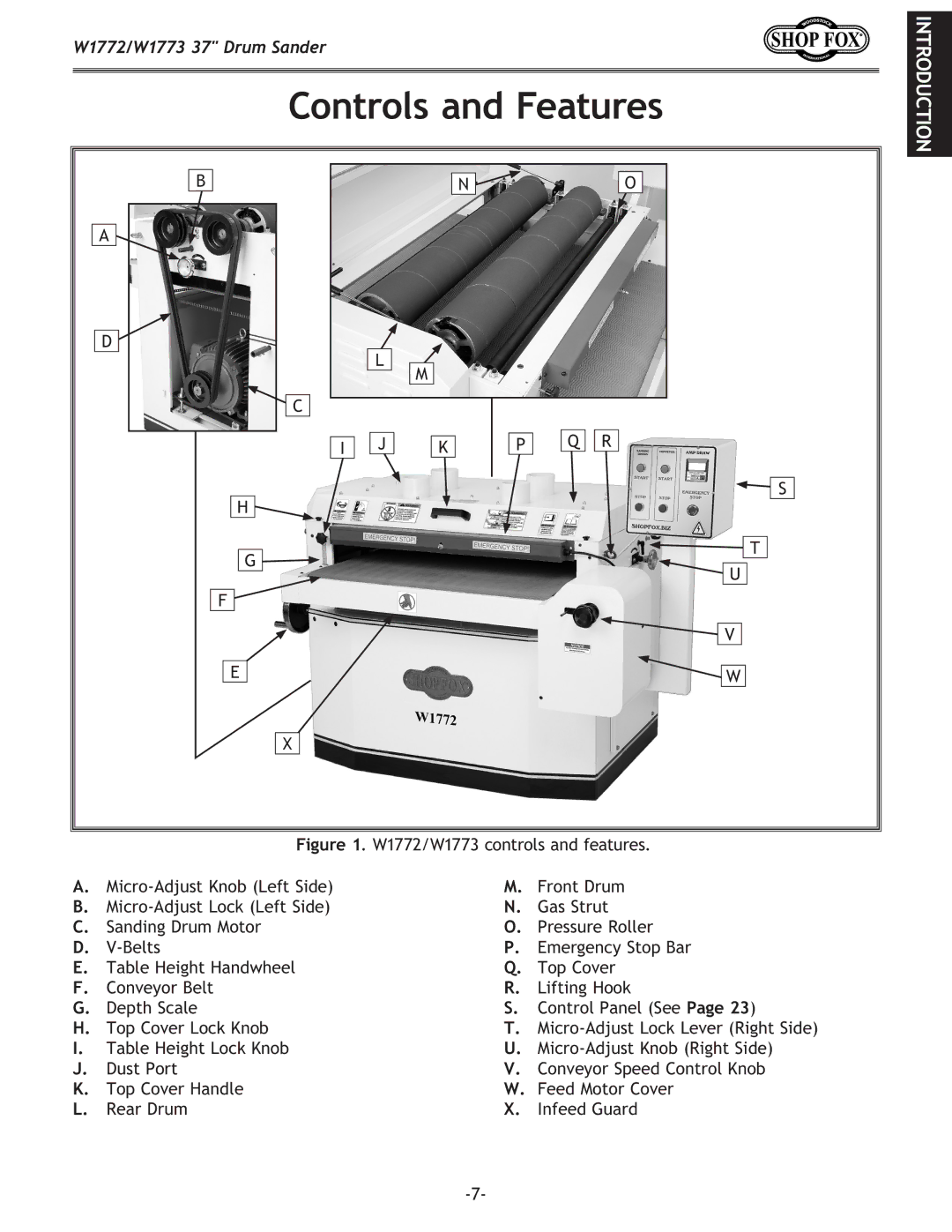

W1772/W1773 37" Drum Sander

Rewiring W1773 to 440V

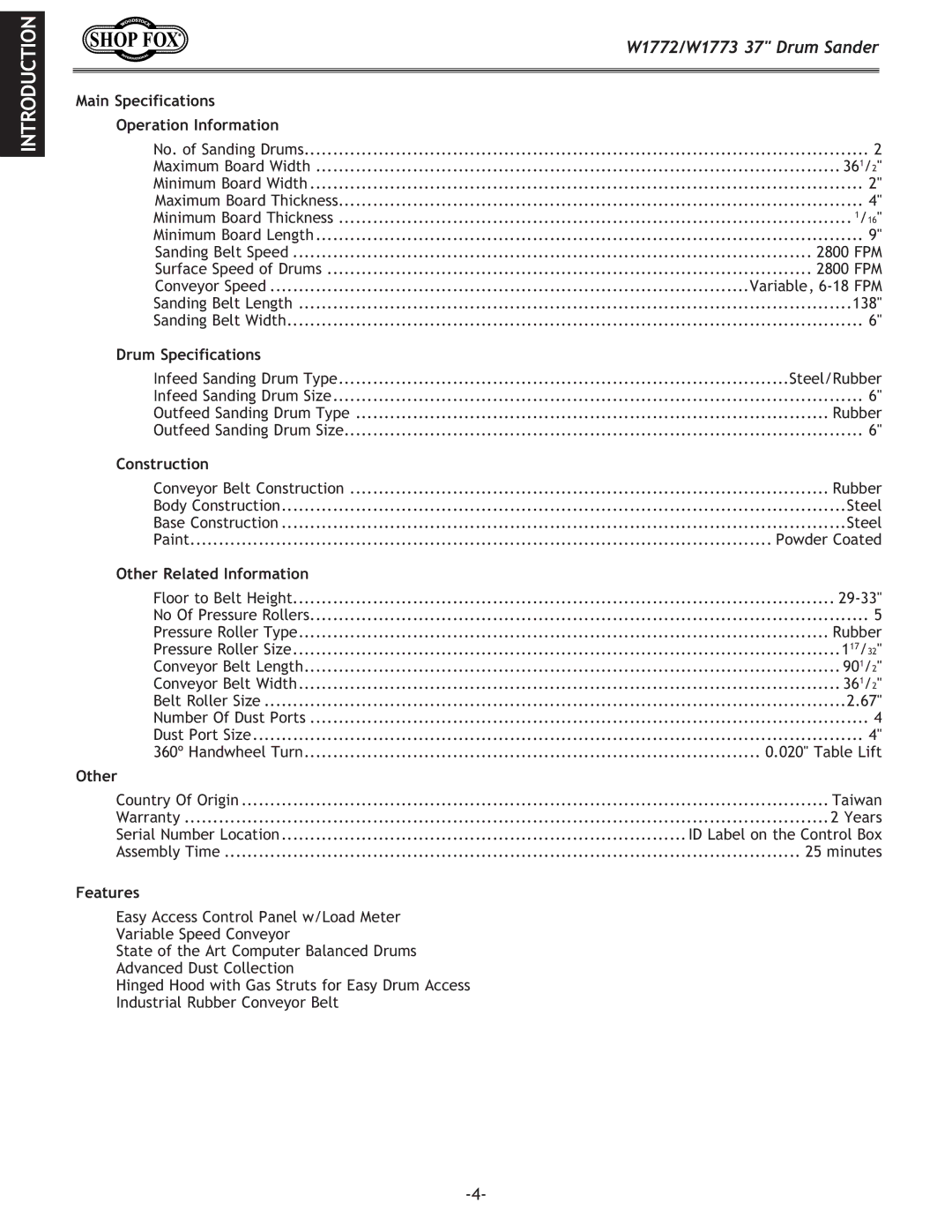

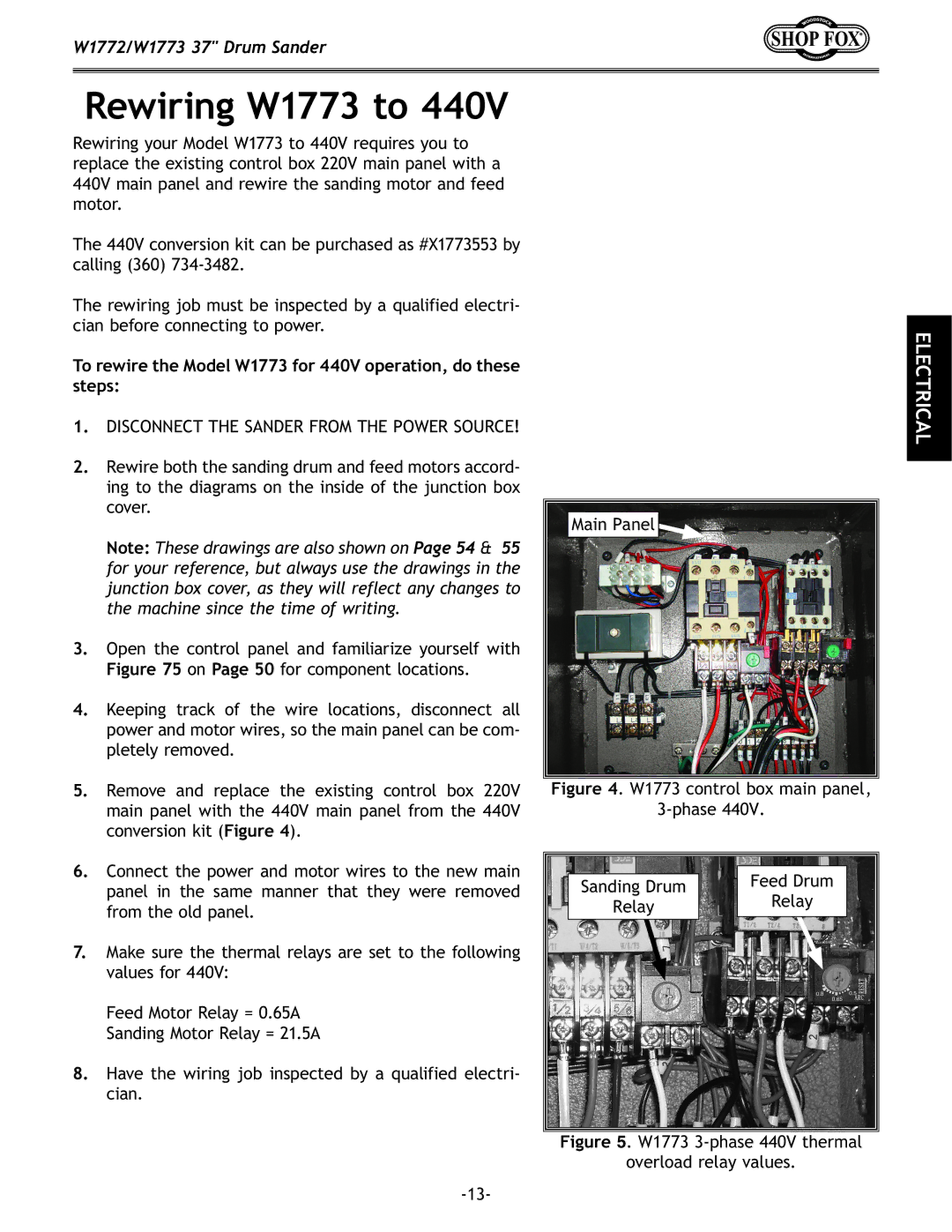

Rewiring your Model W1773 to 440V requires you to replace the existing control box 220V main panel with a 440V main panel and rewire the sanding motor and feed motor.

The 440V conversion kit can be purchased as #X1773553 by calling (360)

The rewiring job must be inspected by a qualified electri- cian before connecting to power.

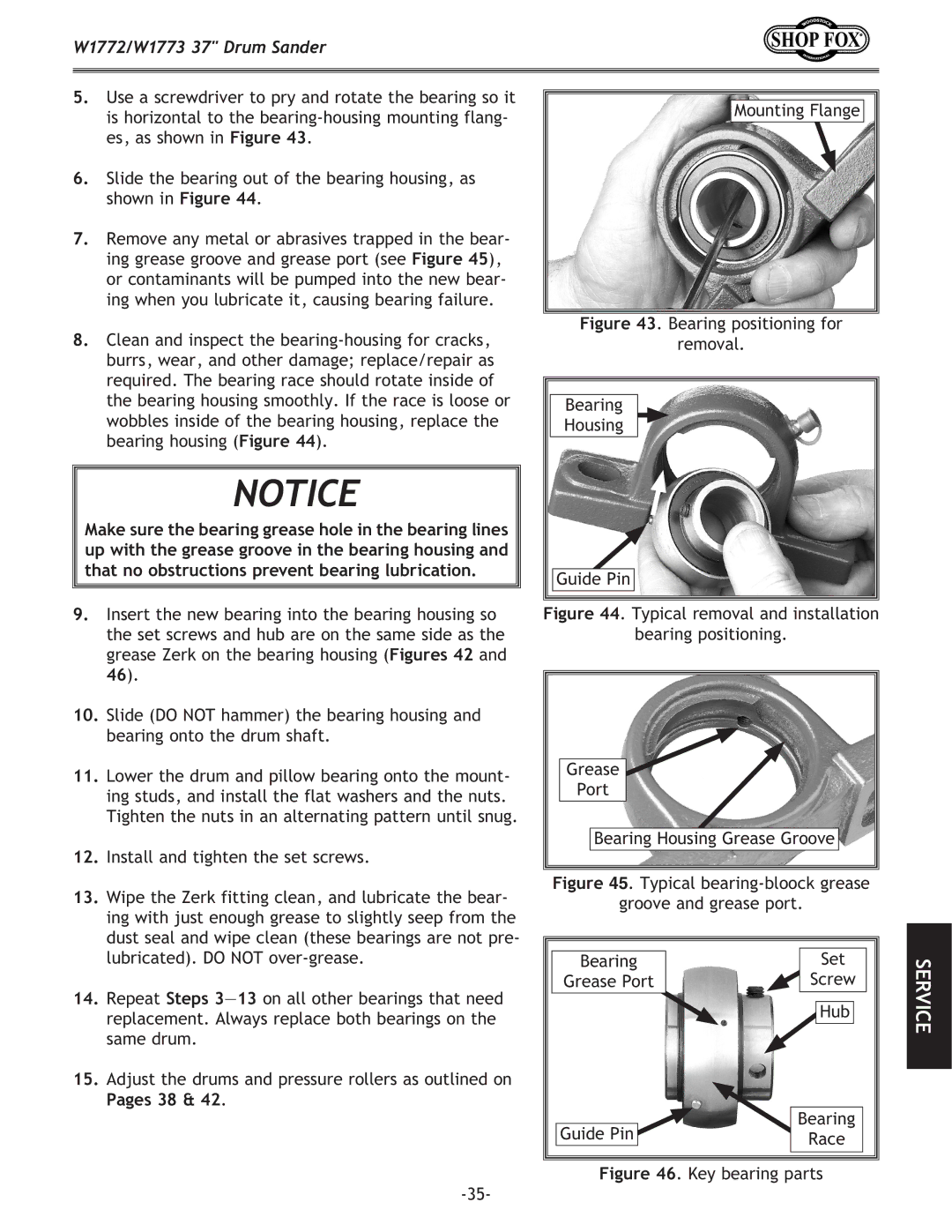

To rewire the Model W1773 for 440V operation, do these steps:

1.DISCONNECT THE SANDER FROM THE POWER SOURCE!

2.Rewire both the sanding drum and feed motors accord- ing to the diagrams on the inside of the junction box cover.

Note: These drawings are also shown on Page 54 & 55 for your reference, but always use the drawings in the junction box cover, as they will reflect any changes to the machine since the time of writing.

3.Open the control panel and familiarize yourself with Figure 75 on Page 50 for component locations.

4.Keeping track of the wire locations, disconnect all power and motor wires, so the main panel can be com- pletely removed.

5.Remove and replace the existing control box 220V main panel with the 440V main panel from the 440V conversion kit (Figure 4).

6.Connect the power and motor wires to the new main panel in the same manner that they were removed from the old panel.

7.Make sure the thermal relays are set to the following values for 440V:

Feed Motor Relay = 0.65A Sanding Motor Relay = 21.5A

8.Have the wiring job inspected by a qualified electri- cian.

Main Panel

Figure 4. W1773 control box main panel,

3-phase 440V.

Sanding Drum | Feed Drum | |

Relay | ||

Relay | ||

|