MAINTENANCE

STEP 7

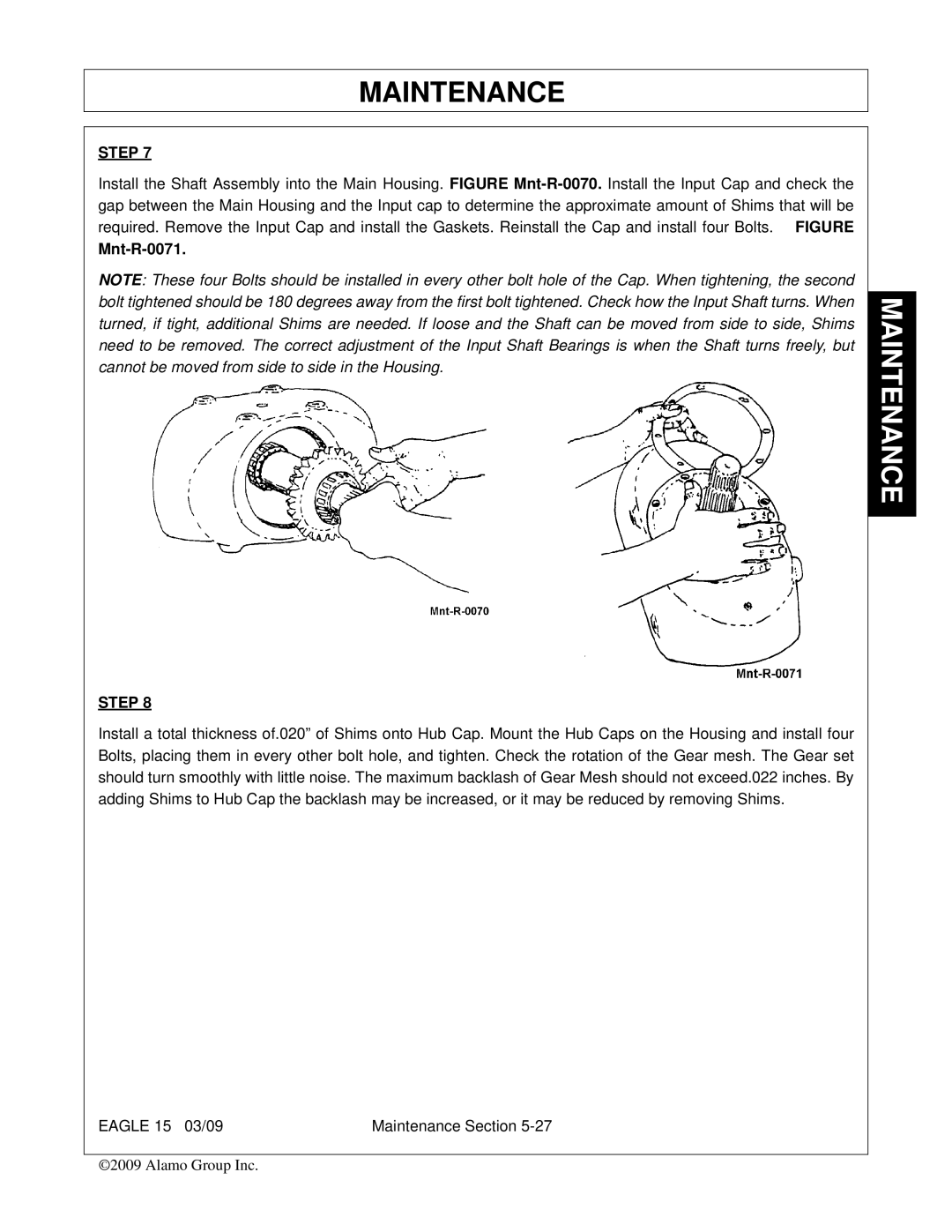

Install the Shaft Assembly into the Main Housing. FIGURE

Mnt-R-0071.

NOTE: These four Bolts should be installed in every other bolt hole of the Cap. When tightening, the second bolt tightened should be 180 degrees away from the first bolt tightened. Check how the Input Shaft turns. When turned, if tight, additional Shims are needed. If loose and the Shaft can be moved from side to side, Shims need to be removed. The correct adjustment of the Input Shaft Bearings is when the Shaft turns freely, but cannot be moved from side to side in the Housing.

STEP 8

Install a total thickness of.020” of Shims onto Hub Cap. Mount the Hub Caps on the Housing and install four Bolts, placing them in every other bolt hole, and tighten. Check the rotation of the Gear mesh. The Gear set should turn smoothly with little noise. The maximum backlash of Gear Mesh should not exceed.022 inches. By adding Shims to Hub Cap the backlash may be increased, or it may be reduced by removing Shims.

EAGLE 15 03/09 | Maintenance Section |

©2009 Alamo Group Inc.