MAINTENANCE

STORAGE

Your rotary cutter represents an investment from which you should get the greatest possible benefit. Therefore, when the season is over, the cutter should be thoroughly checked and prepared for storage so that a minimum amount of work will be required to put it back into operation for the next season. The following are suggested storage procedures:

6.Thoroughly clean the cutter.

7.Lubricate the cutter as covered in Maintenance Section.

8.Tighten all bolts and pins to the recommended torque.

9.Check the cutter for worn or damaged parts. Make replacements immediately.

10.Store the cutter in a clean, dry place with the cutter housing resting on blocks.

11.Use spray

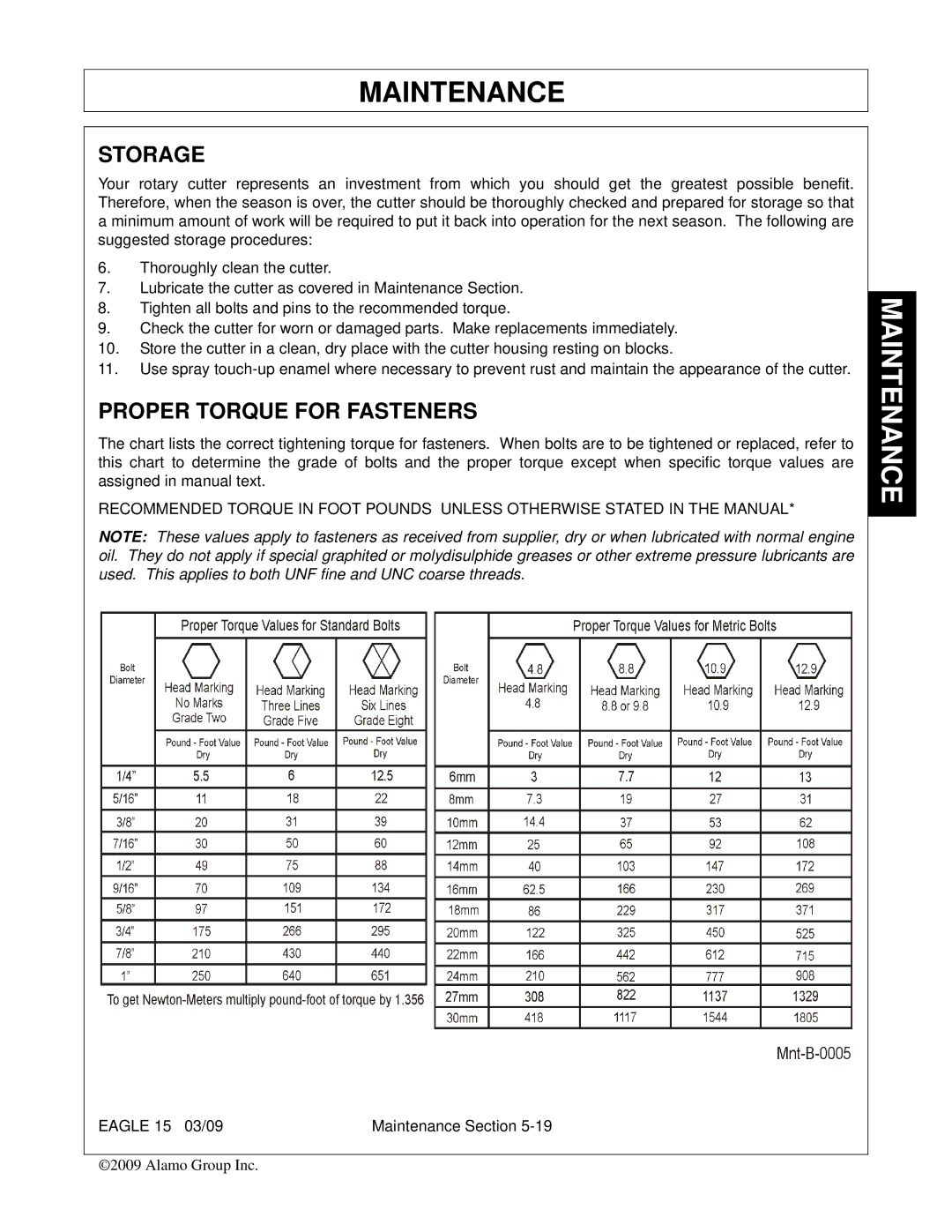

PROPER TORQUE FOR FASTENERS

The chart lists the correct tightening torque for fasteners. When bolts are to be tightened or replaced, refer to this chart to determine the grade of bolts and the proper torque except when specific torque values are assigned in manual text.

RECOMMENDED TORQUE IN FOOT POUNDS UNLESS OTHERWISE STATED IN THE MANUAL*

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This applies to both UNF fine and UNC coarse threads.

EAGLE 15 03/09 | Maintenance Section |

©2009 Alamo Group Inc.