SRP-270

8-4 Lubricants and Adhesive Application

Lubrication and application adhesive plays an important role in maintaining this printer at its initial performance level, throughout a long product life as well as preventing potential troubles. Make sure to apply the specified lubricants or adhesive in the appropriate amounts at the specified intervals.

8-4-1 Lubricant Requirements

Before applying the lubricants during an assembly or disassembly procedure, be sure to first thoroughly clean the part to be lubricated. For details on lubrication.

* Lubrication Classes

Concerning the lubrication interval, lubrication should be performed periodically according to the lubrication classes described below. If lubrication becomes deficient due to cleaning, disassembly or parts replacement, be sure to lubricate the required part regardless of the lubrication interval.

A:Lubrication every 6 months.

B:Lubrication after on overhaul or every 1 million lines

8-4-2 Lubricant Types

The type of oil used greatly influences performance and durability, and special attention is required to its low temperature characteristic. Consequently, the oils to be used with this printer are specified by us on the basis of the result of the thorough analyses of technical data for many types of oils and various experiments.

2 types of oils to be used with this printer are

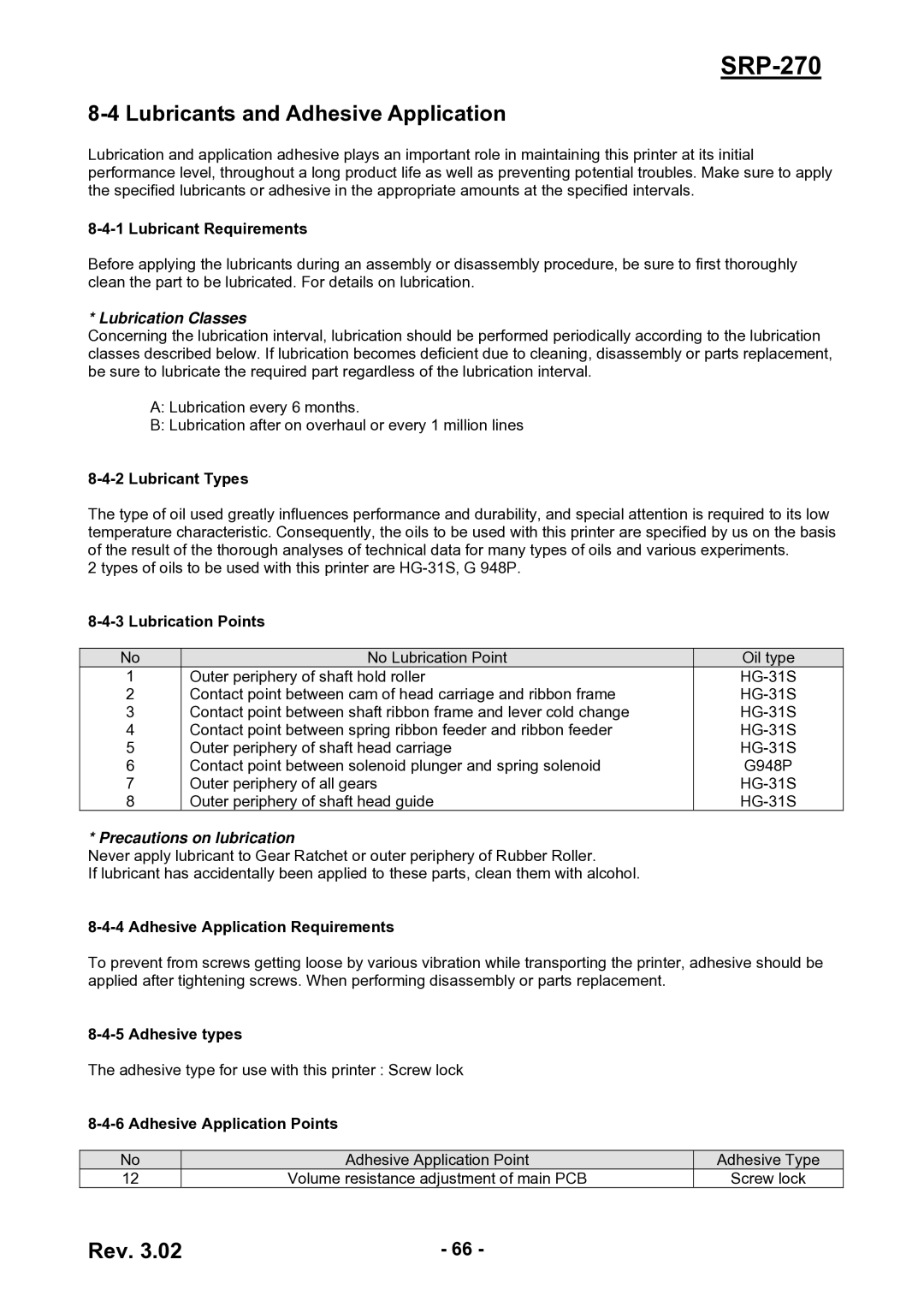

8-4-3 Lubrication Points

No | No Lubrication Point | Oil type |

1 | Outer periphery of shaft hold roller | |

2 | Contact point between cam of head carriage and ribbon frame | |

3 | Contact point between shaft ribbon frame and lever cold change | |

4 | Contact point between spring ribbon feeder and ribbon feeder | |

5 | Outer periphery of shaft head carriage | |

6 | Contact point between solenoid plunger and spring solenoid | G948P |

7 | Outer periphery of all gears | |

8 | Outer periphery of shaft head guide |

* Precautions on lubrication

Never apply lubricant to Gear Ratchet or outer periphery of Rubber Roller.

If lubricant has accidentally been applied to these parts, clean them with alcohol.

8-4-4 Adhesive Application Requirements

To prevent from screws getting loose by various vibration while transporting the printer, adhesive should be applied after tightening screws. When performing disassembly or parts replacement.

The adhesive type for use with this printer : Screw lock

8-4-6 Adhesive Application Points

No | Adhesive Application Point | Adhesive Type |

12 | Volume resistance adjustment of main PCB | Screw lock |

Rev. 3.02 | - 66 - |