|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

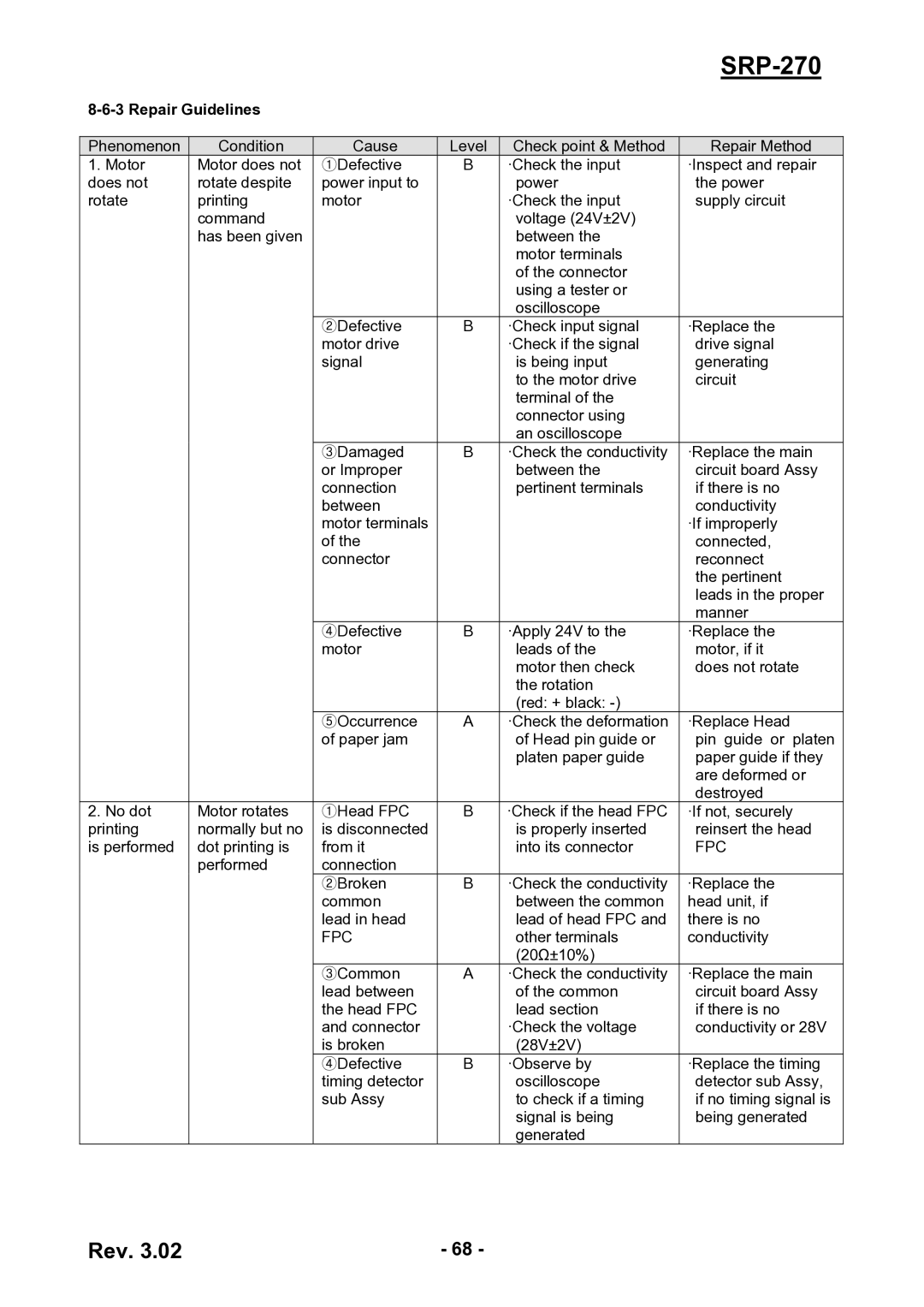

Phenomenon | Condition | Cause | Level | Check point & Method | Repair Method |

1. Motor | Motor does not | ①Defective | B | ·Check the input | ·Inspect and repair |

does not | rotate despite | power input to |

| power | the power |

rotate | printing | motor |

| ·Check the input | supply circuit |

| command |

|

| voltage (24V±2V) |

|

| has been given |

|

| between the |

|

|

|

|

| motor terminals |

|

|

|

|

| of the connector |

|

|

|

|

| using a tester or |

|

|

|

|

| oscilloscope |

|

|

| ②Defective | B | ·Check input signal | ·Replace the |

|

| motor drive |

| ·Check if the signal | drive signal |

|

| signal |

| is being input | generating |

|

|

|

| to the motor drive | circuit |

|

|

|

| terminal of the |

|

|

|

|

| connector using |

|

|

|

|

| an oscilloscope |

|

|

| ③Damaged | B | ·Check the conductivity | ·Replace the main |

|

| or Improper |

| between the | circuit board Assy |

|

| connection |

| pertinent terminals | if there is no |

|

| between |

|

| conductivity |

|

| motor terminals |

|

| ·If improperly |

|

| of the |

|

| connected, |

|

| connector |

|

| reconnect |

|

|

|

|

| the pertinent |

|

|

|

|

| leads in the proper |

|

|

|

|

| manner |

|

| ④Defective | B | ·Apply 24V to the | ·Replace the |

|

| motor |

| leads of the | motor, if it |

|

|

|

| motor then check | does not rotate |

|

|

|

| the rotation |

|

|

|

|

| (red: + black: |

|

|

| ⑤Occurrence | A | ·Check the deformation | ·Replace Head |

|

| of paper jam |

| of Head pin guide or | pin guide or platen |

|

|

|

| platen paper guide | paper guide if they |

|

|

|

|

| are deformed or |

|

|

|

|

| destroyed |

2. No dot | Motor rotates | ①Head FPC | B | ·Check if the head FPC | ·If not, securely |

printing | normally but no | is disconnected |

| is properly inserted | reinsert the head |

is performed | dot printing is | from it |

| into its connector | FPC |

| performed | connection |

|

|

|

|

| ②Broken | B | ·Check the conductivity | ·Replace the |

|

| common |

| between the common | head unit, if |

|

| lead in head |

| lead of head FPC and | there is no |

|

| FPC |

| other terminals | conductivity |

|

|

|

| (20Ω±10%) |

|

|

| ③Common | A | ·Check the conductivity | ·Replace the main |

|

| lead between |

| of the common | circuit board Assy |

|

| the head FPC |

| lead section | if there is no |

|

| and connector |

| ·Check the voltage | conductivity or 28V |

|

| is broken |

| (28V±2V) |

|

|

| ④Defective | B | ·Observe by | ·Replace the timing |

|

| timing detector |

| oscilloscope | detector sub Assy, |

|

| sub Assy |

| to check if a timing | if no timing signal is |

|

|

|

| signal is being | being generated |

|

|

|

| generated |

|

Rev. 3.02 | - 68 - |