Repetitive Crosscutting

REPETITIVE CROSSCUTTING is known as cutting a quantity of pieces the same length without having to mark each piece. When making repetitive cuts from a long workpiece, make sure it is supported – see Fig. 58.

! | WARNING | Never use the rip fence as a direct length stop | |

because the cutoff piece could bind between the | |||

fence and the blade causing kickback. | |||

|

| When attaching the facing block, make sure the | |

! | WARNING | ||

block is well in front of the sawblade, because | |||

|

| ||

the cutoff piece could bind between the fence and the blade causing kickback.

MAKING THE FACING BLOCK

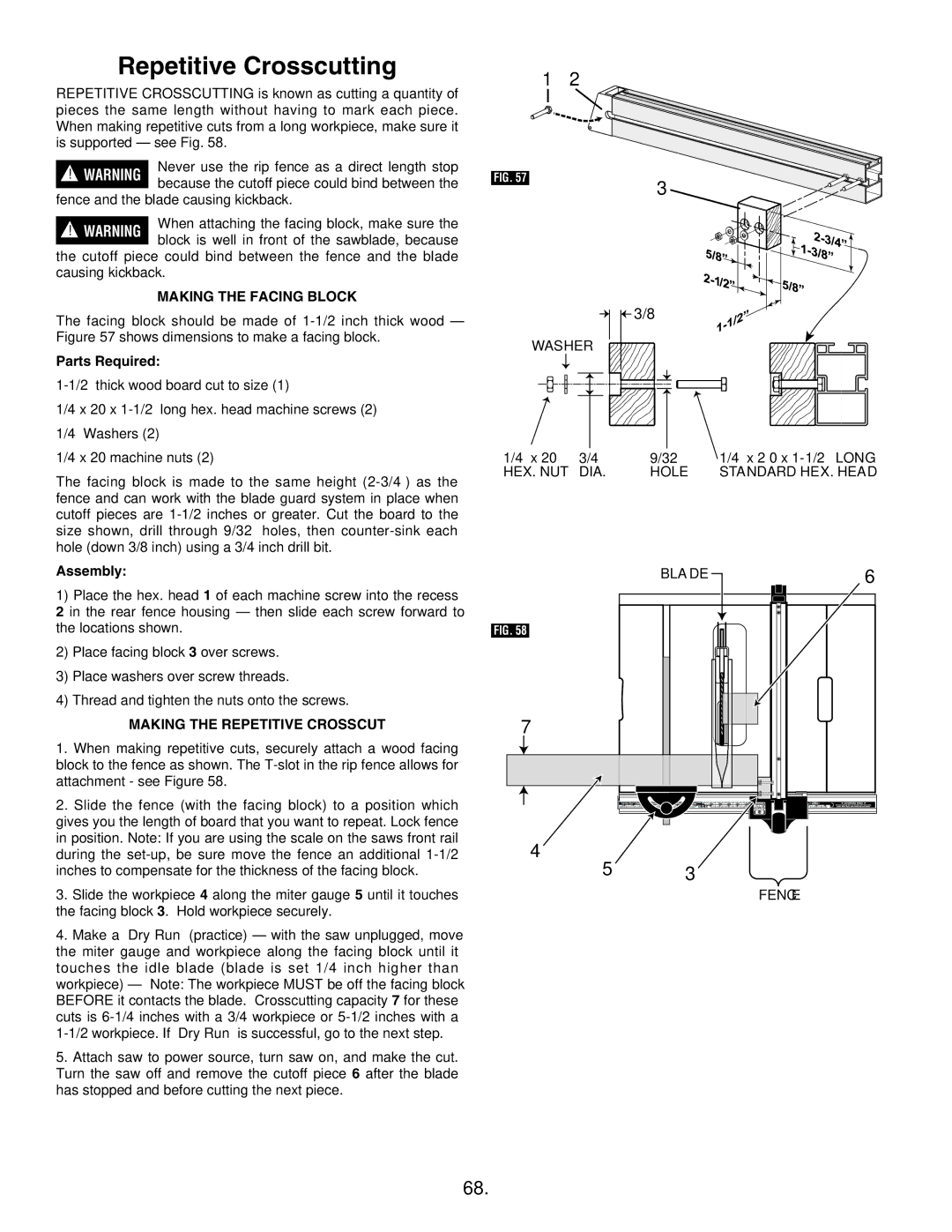

The facing block should be made of

Parts Required:

1/4 x 20 x

1/4” Washers (2)

1/4 x 20 machine nuts (2)

The facing block is made to the same height

Assembly:

1 2

FIG. 57

WASHER

1/4” x 20 | 3/4” |

HEX. NUT | DIA. |

3

![]() 3/8”

3/8”

9/32” | 1/4” x 20 x |

HOLE | STANDARD HEX. HEAD |

BLADE6

1)Place the hex. head 1 of each machine screw into the recess 2 in the rear fence housing – then slide each screw forward to the locations shown.

2)Place facing block 3 over screws.

3)Place washers over screw threads.

4)Thread and tighten the nuts onto the screws.

MAKING THE REPETITIVE CROSSCUT

1.When making repetitive cuts, securely attach a wood facing block to the fence as shown. The

2.Slide the fence (with the facing block) to a position which gives you the length of board that you want to repeat. Lock fence in position. Note: If you are using the scale on the saws front rail during the

3.Slide the workpiece 4 along the miter gauge 5 until it touches the facing block 3. Hold workpiece securely.

4.Make a “Dry Run” (practice) – with the saw unplugged, move the miter gauge and workpiece along the facing block until it touches the idle blade (blade is set 1/4 inch higher than workpiece) – Note: The workpiece MUST be off the facing block BEFORE it contacts the blade. Crosscutting capacity 7 for these cuts is

5.Attach saw to power source, turn saw on, and make the cut. Turn the saw off and remove the cutoff piece 6 after the blade has stopped and before cutting the next piece.

FIG. 58

7 |

|

4 |

|

5 | 3 |

| FENCE |

68.