7.Keep your hands clear of the blade and out of the path of the blade.

8.If the blade stalls or stops while cutting, TURN SWITCH OFF before attempting to free the blade.

9.Do not reach over or behind the blade to pull the workpiece through the cut … to support long or heavy workpieces … to remove small

10.Do not pick up small pieces of

11.Do not remove small pieces of

12.If workpiece is warped, place the CONCAVE side DOWN. This will prevent it from rocking while it is being ripped.

RIP FENCE AUXILIARY FACING

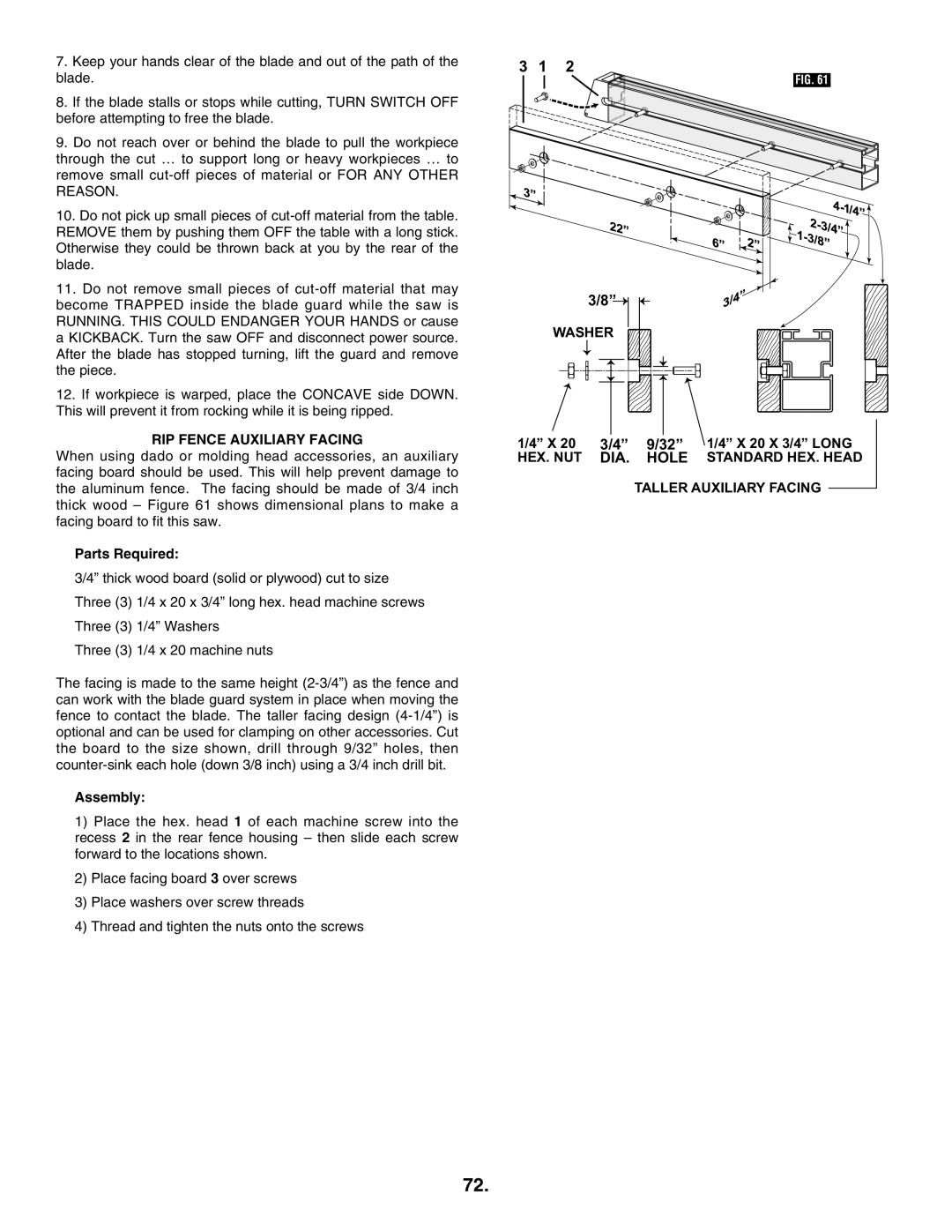

When using dado or molding head accessories, an auxiliary facing board should be used. This will help prevent damage to the aluminum fence. The facing should be made of 3/4 inch thick wood – Figure 61 shows dimensional plans to make a facing board to fit this saw.

Parts Required:

3/4” thick wood board (solid or plywood) cut to size

Three (3) 1/4 x 20 x 3/4” long hex. head machine screws

Three (3) 1/4” Washers

Three (3) 1/4 x 20 machine nuts

The facing is made to the same height

Assembly:

1)Place the hex. head 1 of each machine screw into the recess 2 in the rear fence housing – then slide each screw forward to the locations shown.

2)Place facing board 3 over screws

3)Place washers over screw threads

4)Thread and tighten the nuts onto the screws

3 1 2

FIG. 61

3/8” ![]()

WASHER

1/4” X 20 | 3/4” | 9/32” | 1/4” X 20 X 3/4” LONG |

HEX. NUT | DIA. | HOLE | STANDARD HEX. HEAD |

TALLER AUXILIARY FACING

72.