OPERATION

2.Open start valve (turn fully vertical) and both Drain Valves to prevent air pressure

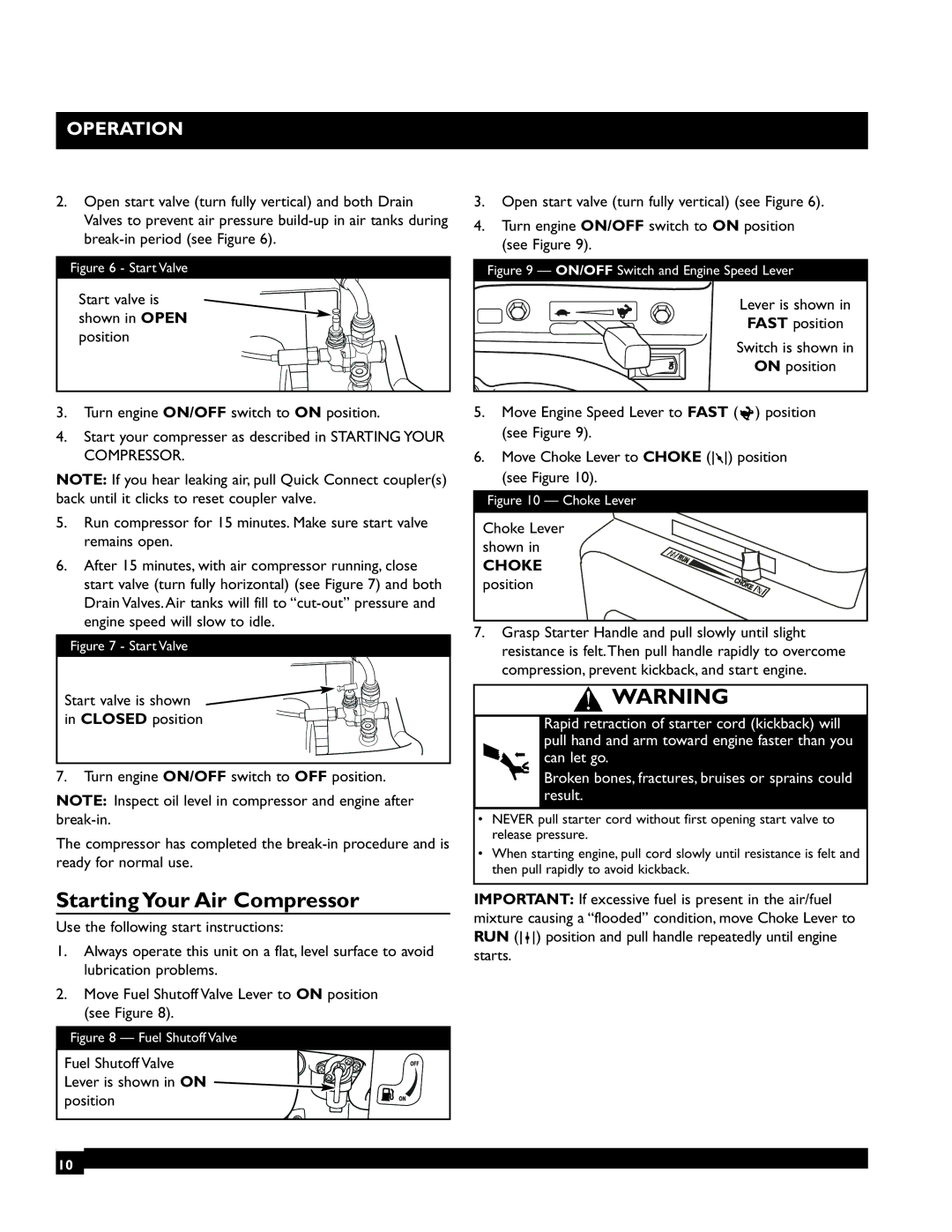

Figure 6 - Start Valve

Start valve is shown in OPEN position

3.Turn engine ON/OFF switch to ON position.

4.Start your compresser as described in STARTING YOUR COMPRESSOR.

NOTE: If you hear leaking air, pull Quick Connect coupler(s) back until it clicks to reset coupler valve.

5.Run compressor for 15 minutes. Make sure start valve remains open.

6.After 15 minutes, with air compressor running, close start valve (turn fully horizontal) (see Figure 7) and both Drain Valves. Air tanks will fill to

Figure 7 - Start Valve

Start valve is shown  in CLOSED position

in CLOSED position

7.Turn engine ON/OFF switch to OFF position.

NOTE: Inspect oil level in compressor and engine after

The compressor has completed the

Starting Your Air Compressor

Use the following start instructions:

1.Always operate this unit on a flat, level surface to avoid lubrication problems.

2.Move Fuel Shutoff Valve Lever to ON position (see Figure 8).

Figure 8 — Fuel Shutoff Valve

Fuel Shutoff Valve Lever is shown in ON position

10

3.Open start valve (turn fully vertical) (see Figure 6).

4.Turn engine ON/OFF switch to ON position (see Figure 9).

Figure 9 — ON/OFF Switch and Engine Speed Lever

Lever is shown in

FAST position

Switch is shown in

ON position

5.Move Engine Speed Lever to FAST ( ![]() ) position (see Figure 9).

) position (see Figure 9).

6.Move Choke Lever to CHOKE (![]() ) position (see Figure 10).

) position (see Figure 10).

Figure 10 — Choke Lever

Choke Lever shown in

CHOKE

position

7.Grasp Starter Handle and pull slowly until slight resistance is felt.Then pull handle rapidly to overcome compression, prevent kickback, and start engine.

![]() WARNING

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward engine faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

•NEVER pull starter cord without first opening start valve to release pressure.

•When starting engine, pull cord slowly until resistance is felt and then pull rapidly to avoid kickback.

IMPORTANT: If excessive fuel is present in the air/fuel mixture causing a “flooded” condition, move Choke Lever to RUN ( ![]() ) position and pull handle repeatedly until engine starts.

) position and pull handle repeatedly until engine starts.