OPERATION

8.Move Choke Lever to RUN ( ![]() ) position a short distance at a time over several seconds in warm weather or several minutes in cold weather. Let engine run smoothly before each change. Operate with choke in RUN position.

) position a short distance at a time over several seconds in warm weather or several minutes in cold weather. Let engine run smoothly before each change. Operate with choke in RUN position.

![]() WARNING

WARNING

Running engines produce heat.Temperature of muffler and nearby areas can reach or exceed 150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles, structures or damage fuel tank causing a fire.

•DO NOT touch hot surfaces and avoid hot exhaust gases.

•Allow equipment to cool before touching.

•Keep at least 5 feet (152 cm) of clearance on all sides of air compressor including overhead.

•Code of Federal Regulation (CFR) Title 36 Parks, Forests, and Public Property require equipment powered by an internal combustion engine to have a spark arrester, maintained in effective working order, complying to USDA Forest service standard

9.After engine has been running

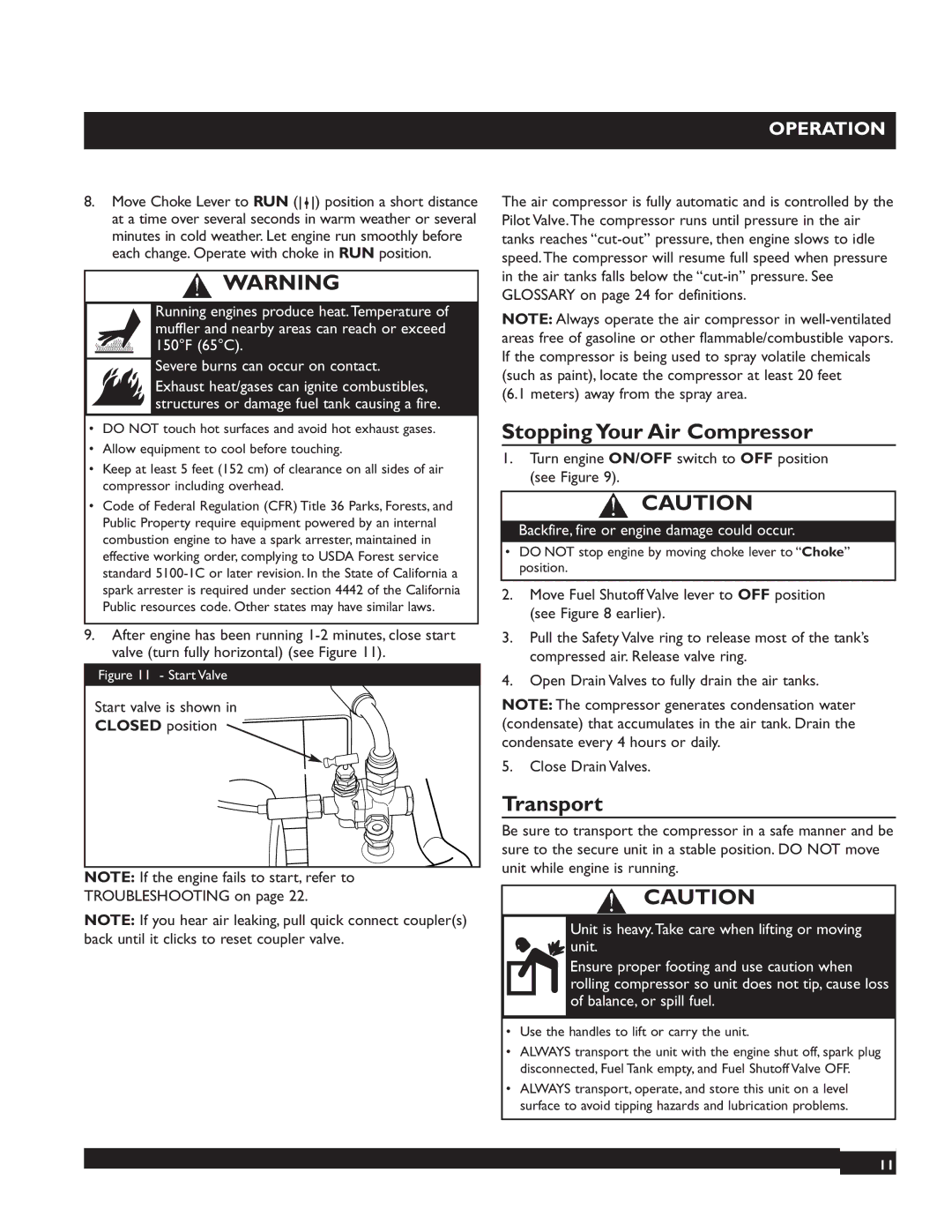

Figure 11 - Start Valve

Start valve is shown in

CLOSED position

NOTE: If the engine fails to start, refer to

TROUBLESHOOTING on page 22.

NOTE: If you hear air leaking, pull quick connect coupler(s) back until it clicks to reset coupler valve.

The air compressor is fully automatic and is controlled by the Pilot Valve.The compressor runs until pressure in the air tanks reaches

NOTE: Always operate the air compressor in

(6.1 meters) away from the spray area.

Stopping Your Air Compressor

1.Turn engine ON/OFF switch to OFF position (see Figure 9).

CAUTION

Backfire, fire or engine damage could occur.

•DO NOT stop engine by moving choke lever to “Choke” position.

2.Move Fuel Shutoff Valve lever to OFF position (see Figure 8 earlier).

3.Pull the Safety Valve ring to release most of the tank’s compressed air. Release valve ring.

4.Open Drain Valves to fully drain the air tanks.

NOTE: The compressor generates condensation water (condensate) that accumulates in the air tank. Drain the condensate every 4 hours or daily.

5.Close Drain Valves.

Transport

Be sure to transport the compressor in a safe manner and be sure to the secure unit in a stable position. DO NOT move unit while engine is running.

CAUTION

Unit is heavy.Take care when lifting or moving ![]() unit.

unit.

Ensure proper footing and use caution when rolling compressor so unit does not tip, cause loss of balance, or spill fuel.

•Use the handles to lift or carry the unit.

•ALWAYS transport the unit with the engine shut off, spark plug disconnected, Fuel Tank empty, and Fuel Shutoff Valve OFF.

•ALWAYS transport, operate, and store this unit on a level surface to avoid tipping hazards and lubrication problems.

11