ASSEMBLY

3.Slowly add fuel to fuel tank. Fill to red fuel level indicator (see Figure 1). Be careful not to overfill tank.

Figure 1 - Add Fuel

Fuel Level Indicator |

4.Replace fuel cap and wait for any spilled fuel to evaporate.

CAUTION! Some fuels, called oxygenated or reformulated fuel, are fuels blended with alcohols or ethers. Excessive amounts of these blends can damage the fuel system or cause performance problems. If any undesirable operating indications occur, use fuel with a lower percentage of alcohol or ether.

Fresh fuel prevents gum from forming in the fuel system or on essential carburetor parts. Purchase only quantities of fuel that can be used within 30 days.

Install Pump Oil Breather Cap

1.Ensure compressor is resting on a flat, level surface.

2.Open Drain Valves (rotate fully counterclockwise) to release residual air pressure

Figure 2 Drain Valve

Drain Valve shown in Open position

CAUTION

Residual compressed air in pump can propel oil and cause soft tissue damage to exposed skin or eyes leading to severe injury.

•Always wear ANSI Z87.1 approved safety glasses with side shields.

3.Remove and discard shipping cap.

4.Install pump oil breather cap into the oil fill (see Figure 3).

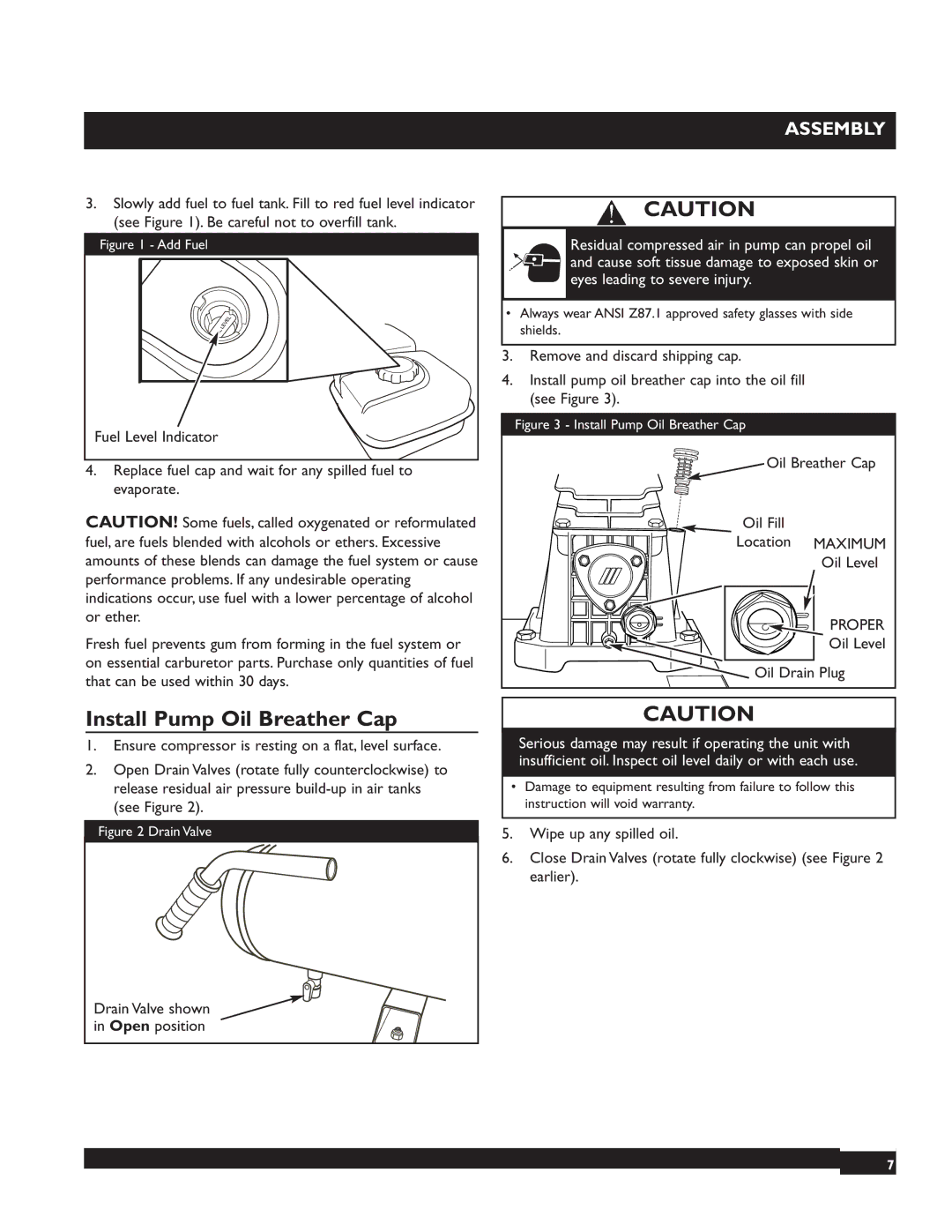

Figure 3 - Install Pump Oil Breather Cap

Oil Breather Cap | |

Oil Fill |

|

Location | MAXIMUM |

| Oil Level |

| PROPER |

| Oil Level |

Oil Drain Plug | |

CAUTION |

|

Serious damage may result if operating the unit with insufficient oil. Inspect oil level daily or with each use.

•Damage to equipment resulting from failure to follow this instruction will void warranty.

5.Wipe up any spilled oil.

6.Close Drain Valves (rotate fully clockwise) (see Figure 2 earlier).

7