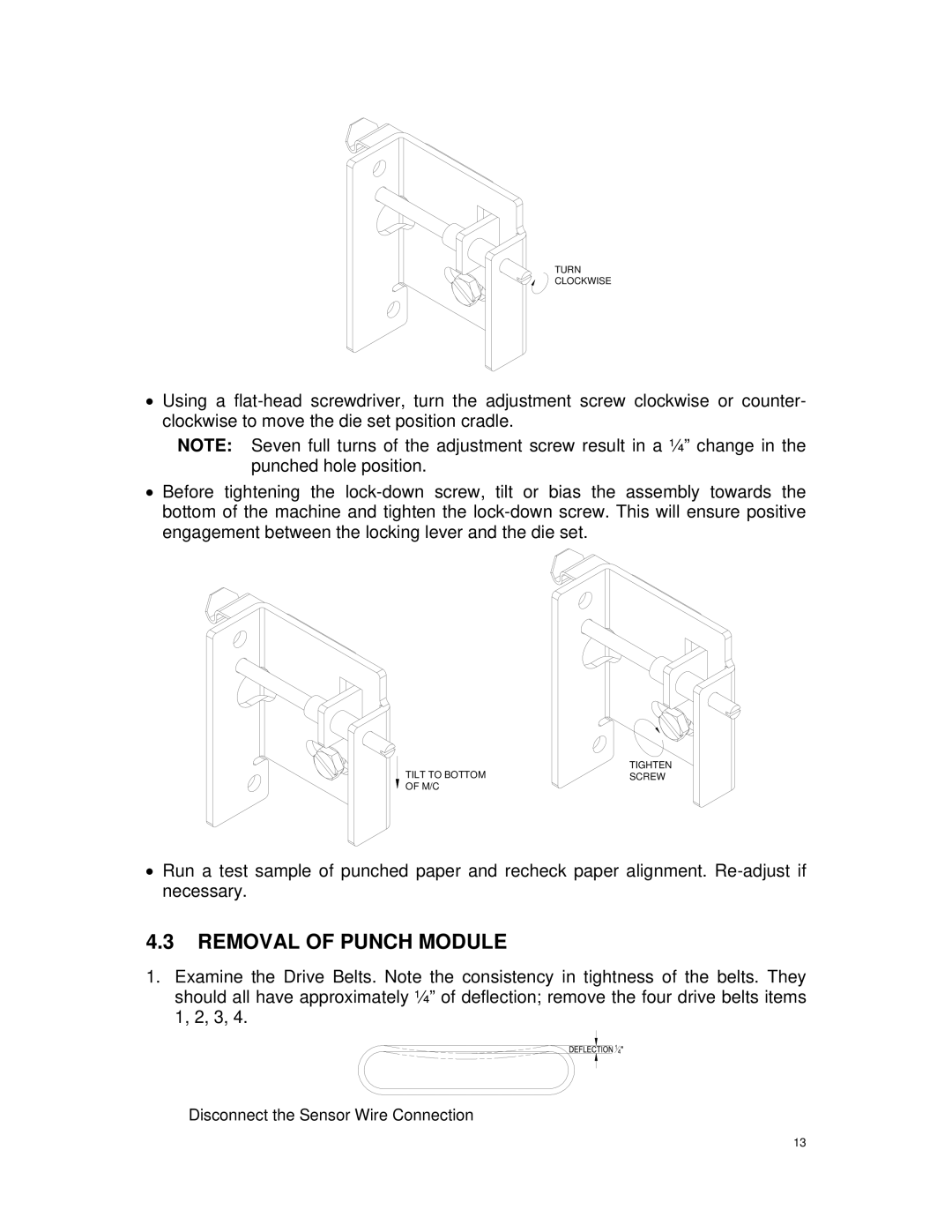

TURN

CLOCKWISE

•Using a

NOTE: Seven full turns of the adjustment screw result in a ¼” change in the punched hole position.

•Before tightening the

TIGHTEN

TILT TO BOTTOMSCREW

OF M/C

•Run a test sample of punched paper and recheck paper alignment.

4.3REMOVAL OF PUNCH MODULE

1.Examine the Drive Belts. Note the consistency in tightness of the belts. They should all have approximately ¼” of deflection; remove the four drive belts items 1, 2, 3, 4.

Disconnect the Sensor Wire Connection

13