2.Remove 4 screws in front and 2 in back

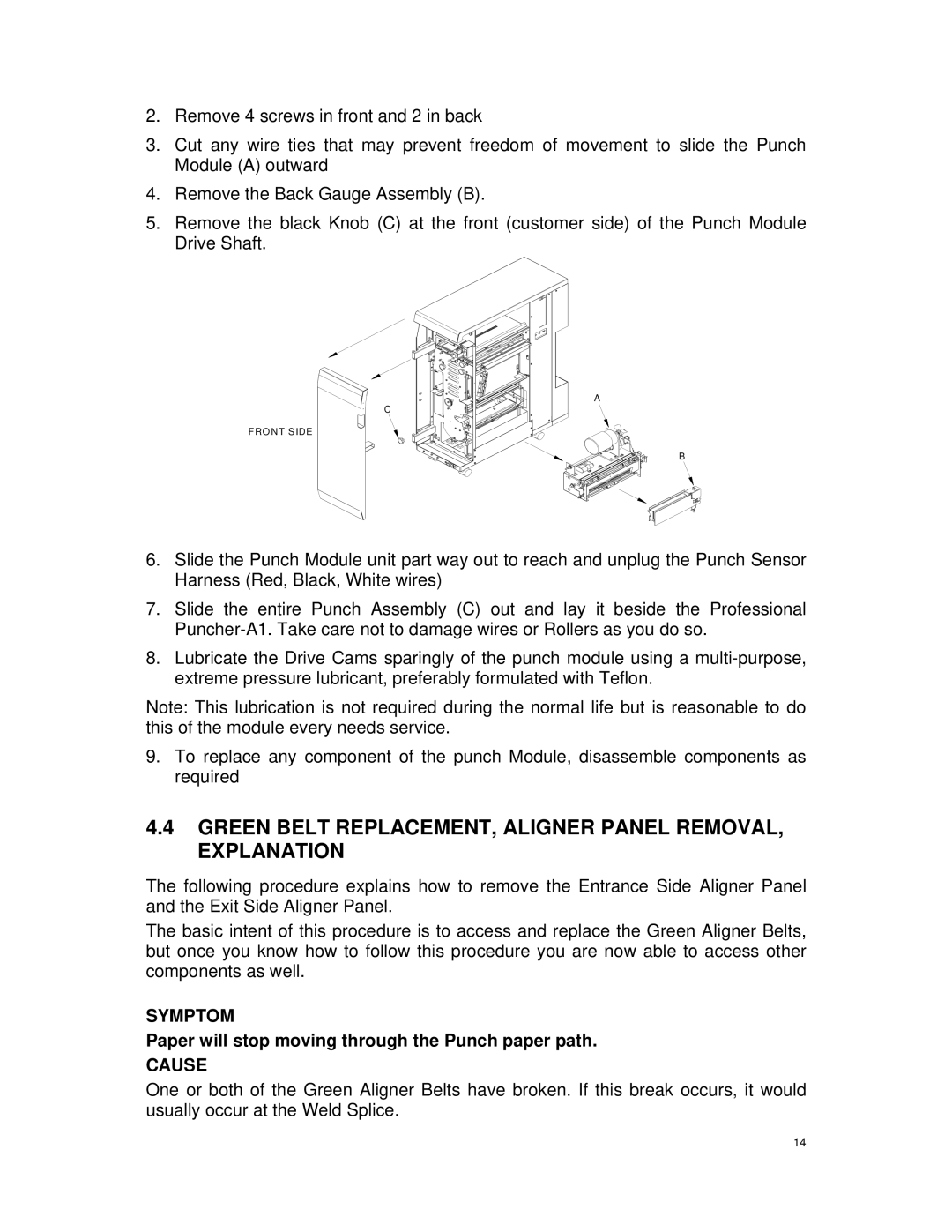

3.Cut any wire ties that may prevent freedom of movement to slide the Punch Module (A) outward

4.Remove the Back Gauge Assembly (B).

5.Remove the black Knob (C) at the front (customer side) of the Punch Module Drive Shaft.

C

FRONT SIDE

A

B

6.Slide the Punch Module unit part way out to reach and unplug the Punch Sensor Harness (Red, Black, White wires)

7.Slide the entire Punch Assembly (C) out and lay it beside the Professional

8.Lubricate the Drive Cams sparingly of the punch module using a

Note: This lubrication is not required during the normal life but is reasonable to do this of the module every needs service.

9.To replace any component of the punch Module, disassemble components as required

4.4GREEN BELT REPLACEMENT, ALIGNER PANEL REMOVAL, EXPLANATION

The following procedure explains how to remove the Entrance Side Aligner Panel and the Exit Side Aligner Panel.

The basic intent of this procedure is to access and replace the Green Aligner Belts, but once you know how to follow this procedure you are now able to access other components as well.

SYMPTOM

Paper will stop moving through the Punch paper path.

CAUSE

One or both of the Green Aligner Belts have broken. If this break occurs, it would usually occur at the Weld Splice.

14