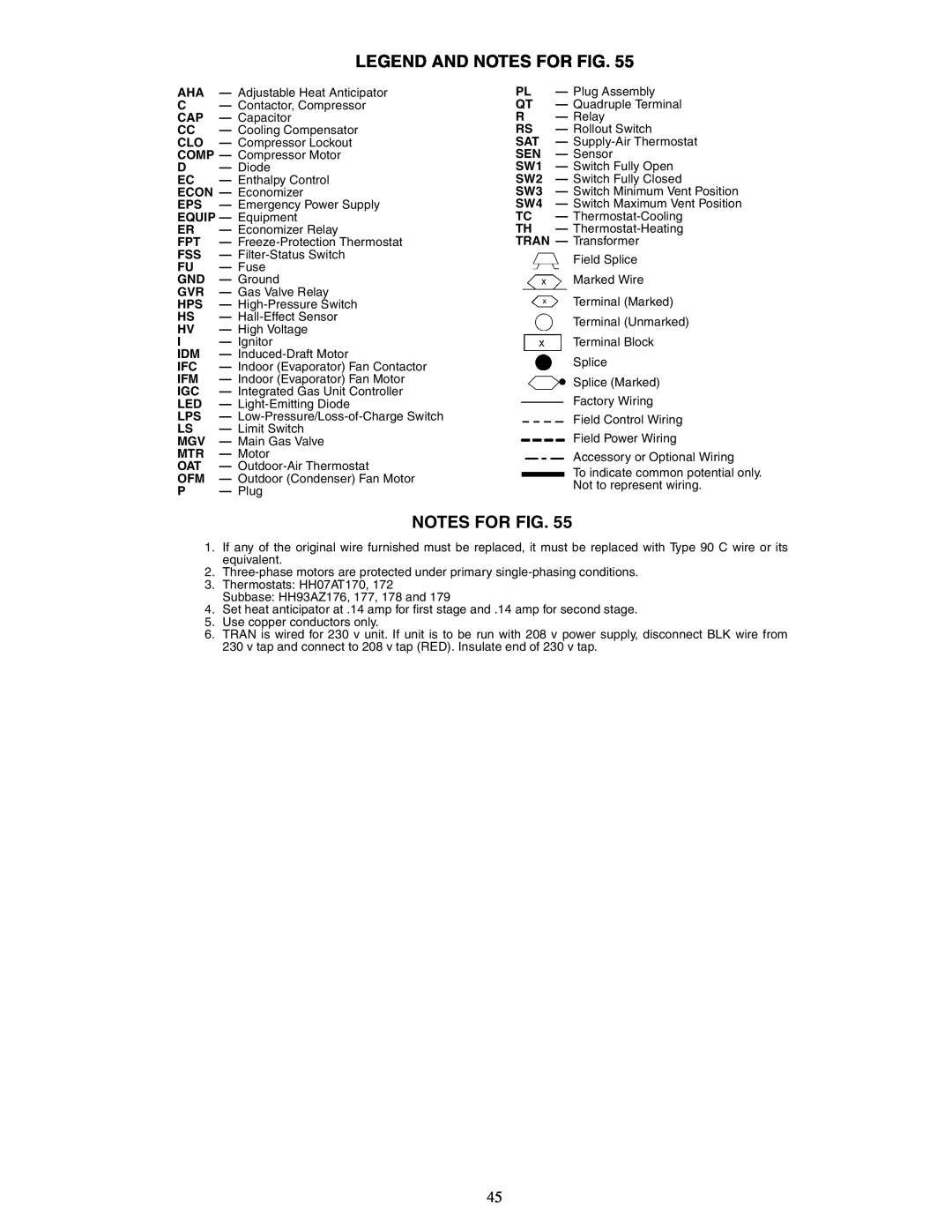

LEGEND AND NOTES FOR FIG. 55

AHA — Adjustable Heat Anticipator

C— Contactor, Compressor CAP — Capacitor

CC— Cooling Compensator CLO — Compressor Lockout COMP — Compressor Motor

D— Diode

EC | — Enthalpy Control |

ECON — Economizer | |

EPS | — Emergency Power Supply |

EQUIP — Equipment | |

ER | — Economizer Relay |

FPT | — |

FSS | — |

FU | — Fuse |

GND | — Ground |

GVR | — Gas Valve Relay |

HPS | — |

HS | — |

HV | — High Voltage |

I— Ignitor

IDM | — |

IFC | — Indoor (Evaporator) Fan Contactor |

IFM | — Indoor (Evaporator) Fan Motor |

IGC | — Integrated Gas Unit Controller |

LED | — |

LPS | — |

LS | — Limit Switch |

MGV | — Main Gas Valve |

MTR | — Motor |

OAT | — |

OFM | — Outdoor (Condenser) Fan Motor |

P— Plug

PL — Plug Assembly

QT — Quadruple Terminal

R— Relay

RS | — Rollout Switch |

SAT | — |

SEN | — Sensor |

SW1 | — Switch Fully Open |

SW2 | — Switch Fully Closed |

SW3 | — Switch Minimum Vent Position |

SW4 | — Switch Maximum Vent Position |

TC | — |

TH | — |

TRAN — Transformer

Field Splice

Marked Wire

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Splice (Marked)

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

To indicate common potential only. Not to represent wiring.

NOTES FOR FIG. 55

1.If any of the original wire furnished must be replaced, it must be replaced with Type 90 C wire or its equivalent.

2.

3.Thermostats: HH07AT170, 172

Subbase: HH93AZ176, 177, 178 and 179

4.Set heat anticipator at .14 amp for first stage and .14 amp for second stage.

5.Use copper conductors only.

6.TRAN is wired for 230 v unit. If unit is to be run with 208 v power supply, disconnect BLK wire from 230 v tap and connect to 208 v tap (RED). Insulate end of 230 v tap.

45