CAPACITOR Ð The 52S units use a dual capacitor. One part of the capacitor is used with the fan motor. The other part of the capacitor is used by the compressor.

Run circuits on

To evaluate the capacitor, perform a visual check ®rst. A shorted capacitor may give a visual indication of its failure. For example, the

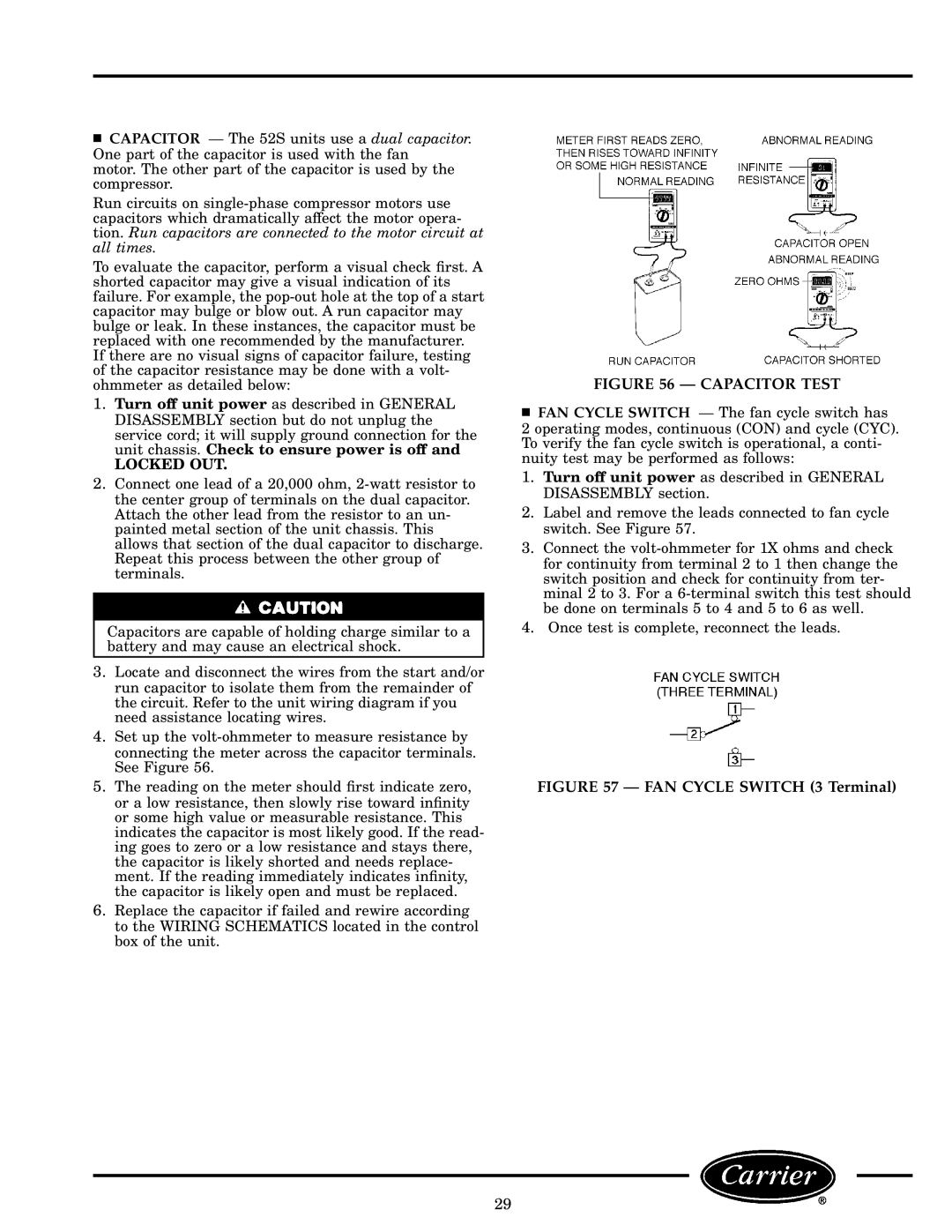

If there are no visual signs of capacitor failure, testing of the capacitor resistance may be done with a volt- ohmmeter as detailed below:

1.Turn off unit power as described in GENERAL DISASSEMBLY section but do not unplug the service cord; it will supply ground connection for the unit chassis. Check to ensure power is off and

LOCKED OUT.

2.Connect one lead of a 20,000 ohm,

Capacitors are capable of holding charge similar to a battery and may cause an electrical shock.

3.Locate and disconnect the wires from the start and/or run capacitor to isolate them from the remainder of the circuit. Refer to the unit wiring diagram if you need assistance locating wires.

4.Set up the

5.The reading on the meter should ®rst indicate zero, or a low resistance, then slowly rise toward in®nity or some high value or measurable resistance. This indicates the capacitor is most likely good. If the read- ing goes to zero or a low resistance and stays there, the capacitor is likely shorted and needs replace- ment. If the reading immediately indicates in®nity, the capacitor is likely open and must be replaced.

6.Replace the capacitor if failed and rewire according to the WIRING SCHEMATICS located in the control box of the unit.

FIGURE 56 Ð CAPACITOR TEST

FAN CYCLE SWITCH Ð The fan cycle switch has

2 operating modes, continuous (CON) and cycle (CYC). To verify the fan cycle switch is operational, a conti- nuity test may be performed as follows:

1.Turn off unit power as described in GENERAL DISASSEMBLY section.

2.Label and remove the leads connected to fan cycle switch. See Figure 57.

3.Connect the

4.Once test is complete, reconnect the leads.

FIGURE 57 Ð FAN CYCLE SWITCH (3 Terminal)

29