Safety Considerations

Contents

Contents

General

Introduction

Unit Sizes and Modular Combinations 30GUN,R

Major System Components

Unit Sizes and Modular Combinations 30GTN,R

Unit Nominal Section a Section B 30GTN,R Tons Unit 30GTN,R

Control Module Communication

Carrier Comfort Network CCN Interface

Thermistor Designations

Status Switches

Output Relay

Page

24 V Control Schematic, Unit Sizes

24 V Control Schematic, Unit Sizes 080-110, 230B-315B

CCN LEN Data Communication Port

Main Base Board

Operating Data

040-110 130-210

Thermistor T3 and T4 Locations

Compressor Thermistor Locations T7 and T8

Belden 8205

Regular Wiring Plenum Wiring Alpha 1895 American

Manufacturer

Columbia D6451 Manhattan M13402 M64430 Quabik 6130

Compressor Protection Control System Module Sizes

Stepper Motor 12 VDC

CEPL130351

30GUN,R

Part Load Data Percent Displacement, Standard Units

Displacement Compressors

Approx

110, 290B

255A 60 Hz

390B 60 Hz

330A/B

360B 50 Hz

390B 50 Hz

B1†

A1,B1 A1†,A2,B1 A1*,B1†,B2

Unloaded compressor Two unloaders, both unloaded

170, 270A

190, 290A, 360A/B

A1*,B1*,B2

Required Hardware for Additional Unloaders

150-210

Head Pressure Control

Pumpout

Power

FAN Arrangement FAN Relay Normal Control

Service Test See Both main power

Scrolling Marquee Display

Modes

GEN.O Test

Strt

Run Status Mode and Sub-Mode Directory

SUB-MODE Keypad Range Item Expansion Comment Entry View

Vers

Service Test Mode and Sub-Mode Directory

SUB-MODE Keypad Range Item Expansion Comment Entry Test

Outs

Temperature Mode and Sub-Mode Directory

Pressure Mode and Sub-Mode Directory

Set Point Mode and Sub-Mode Directory

SUB-MODE Keypad Range Item Expansion Comment Entry GEN.I

Inputs Mode and Sub-Mode Directory

Reading and Changing Chilled Fluid Set Point

Crct

Outputs Mode and Sub-Mode Directory

Configuration Mode and Sub-Mode Directory

SUB-MODE Keypad Range Item Expansion Comment Entry GEN.O

CCN

OPT1

OPT2

EMM

240

Rset

Example of Temperature Reset Return Fluid Configuration

SUB-MODE Keypad Display Item Expansion Comment Entry Rset

Example of Configuring Dual Chiller Control Master Chiller

Example of Configuring Dual Chiller Control Slave Chiller

SUB-MODE Keypad Entry Display Item Expansion Comment Rset

SUB-MODE Keypad Display Item Expansion Comment Entry OPT2

Example of Compressor Lead/Lag Configuration

Time Clock Mode and Sub-Mode Directory

SUB-MODE Keypad Entry Item Expansion Comment Range Time

Setting an Occupied Time Schedule

Operating Mode and Sub-Mode Directory

Mode no Item Expansion Description

Operating Modes

Alarms Mode and Sub-Mode Directory

Example of Reading and Clearing Alarms

Configuration

Configuring Temperature Reset

Mode Keypad SUB-MODE

Entry Expansion

RED LED Entry Expansion Configuration

Configuring Demand Limit

DLS2

Troubleshooting

To 20 mA Demand Limiting

Page

Alarm and Alert Codes

T051

FSM

By Control Method Cause Code Alert GENERATED?

EWT

LCW

T170

T153

T155

T173

T205

T203

T204

T206

Oil Charge

Service

Electronic Components

Compressor OIL Required

Cooler Thermistor Locations

Plugs

Components for Part Number Plugging

Condenser Coils

Cooler Head Bolt Tightening Sequence Typical Tube Sheet

Condenser Fan Adjustment Hz Low Noise Fan Option Units

Dimension FAN Type

Printed Circuit Board Connector

Refrigerant Feed Components Each circuit has

Thermistors Temperature Sensors

5K Thermistor Temperature F vs Resistance/Voltage

Drop B

Drop a

5K Thermistor Temperature C vs Resistance/Voltage

Temp Voltage Resistance Drop

200,510

30GTN,R Units

Pressure Switch Settings Psig kPa

Switch Cutout CUT-IN

30GUN,R Units

PRE-START-UP

System Check

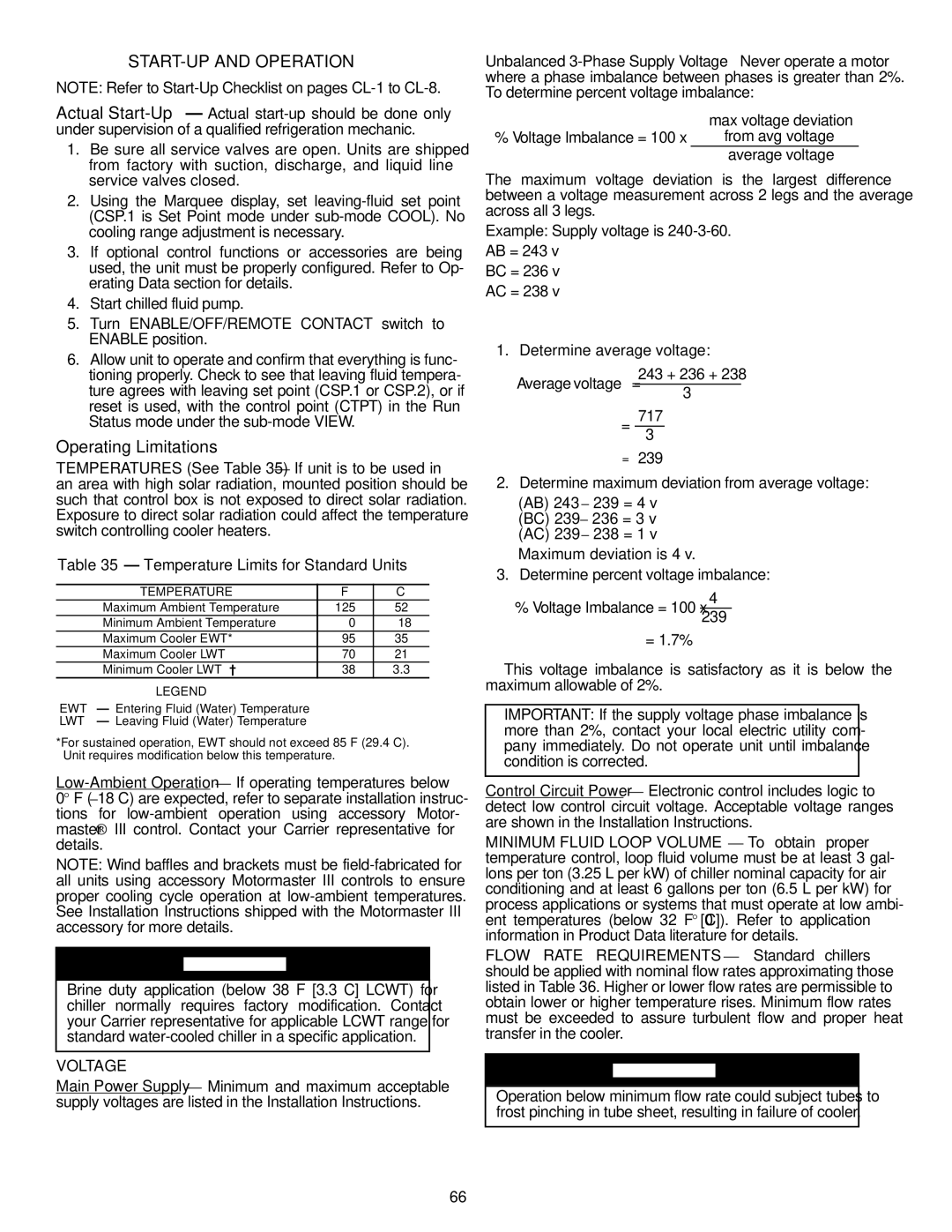

Maximum Ambient Temperature 125

Temperature Limits for Standard Units

Temperature

START-UP and Operation

Field Wiring

Refrigerant Circuit

Nominal and Minimum Cooler Fluid Flow Rates

ALM

CWP

Hgbps

Energy Management Module EMM Wiring

Compressor Expansion Board CXB Accessory Wiring

Description Status Default Units Point

Unit Configuration Settings

OPTIONS1 Options Configuration

Description Status Default Point

OPTIONS2 Options Configuration

Alarmdef Alarm Definition Table

Appendix a CCN Tables

Resetcon Temperature Reset and Demand Limit

Brodefs Broadcast POC Definition Table

Circadio Circuit a Discrete Parameters

Aunit General Unit Parameters

Circaan Circuit a Analog Parameters

Description Status Units Point Forceable

Circban Circuit B Analog Parameters

Circbdio Circuit B Discrete Parameters

Options Unit Parameters

Strthour

Description Status Units Point

Description Status Units Point Defaults

Currmods

CSM/FSM Equipment Table Type 621H, Block

Line Description Point

Description Status Point

Appendix B Fluid Drop Pressure Curves

Cooler Fluid Pressure Drop Curves 30GUN,GUR040-110

Appendix B Fluid Drop Pressure Curves

Cooler Fluid Pressure Drop Curves 30GUN,GUR130-210

Cooler Pressure Drop KEY

Appendix B Fluid Drop Pressure Curves

Cooler Fluid Pressure Drop Curves 30GUN,GUR230B-315B

Cooler Fluid Pressure Drop Curves 30GTN,GTR040-110

Cooler Fluid Pressure Drop Curves 30GTN,GTR130-210

Appendix B Fluid Drop Pressure Curves

Module B 30GTN,GTR230,245 Module B 30GTN,GTR255,290,315

Service Training

Call for Free Catalog

START-UP Checklist for Comfortlink Chiller Systems

Remove and use for job file Preliminary Information

Equipment Chiller Model no

Preliminary Equipment Check Check box if complete

System Fluid Volume in Loop Type System

UnitStart-Up

Unit Start-Up

Ccnb

Description Status Units Value Ctrl

Ccna

Baud

Slct Heating Cooling Setpoint Select

CND.P RMT.A

All Units