Water Supply and Quantity — Check water supply. Water supply should be plentiful and of good quality. See Table 4 for water quality guidelines.

IMPORTANT: Failure to comply with the above required water quality and quantity limitations and the closed- system application design requirements may cause damage to the

In all applications, the quality of the water circulated through the heat exchanger must fall within the ranges listed in the Water Quality Guidelines table. Consult a local water treat- ment firm, independent testing facility, or local water authority for specific recommendations to maintain water quality within the published limits.

•Limit piping materials to only polyethylene fusion in the buried sections of the loop.

•Do not use galvanized or steel fittings at any time due to corrosion.

•Avoid all plastic to metal threaded fittings due to the potential to leak. Use a flange fitted substitute.

•Do not overtighten connections.

•Route piping to avoid service access areas to unit.

•Use

Water Flow

Control Regulator

Valve

Boiler

Drains

Pressure-

Temperature

Plugs

Pressure

Tank

Water Out

Water In

From Pump

Valve

Strainer –

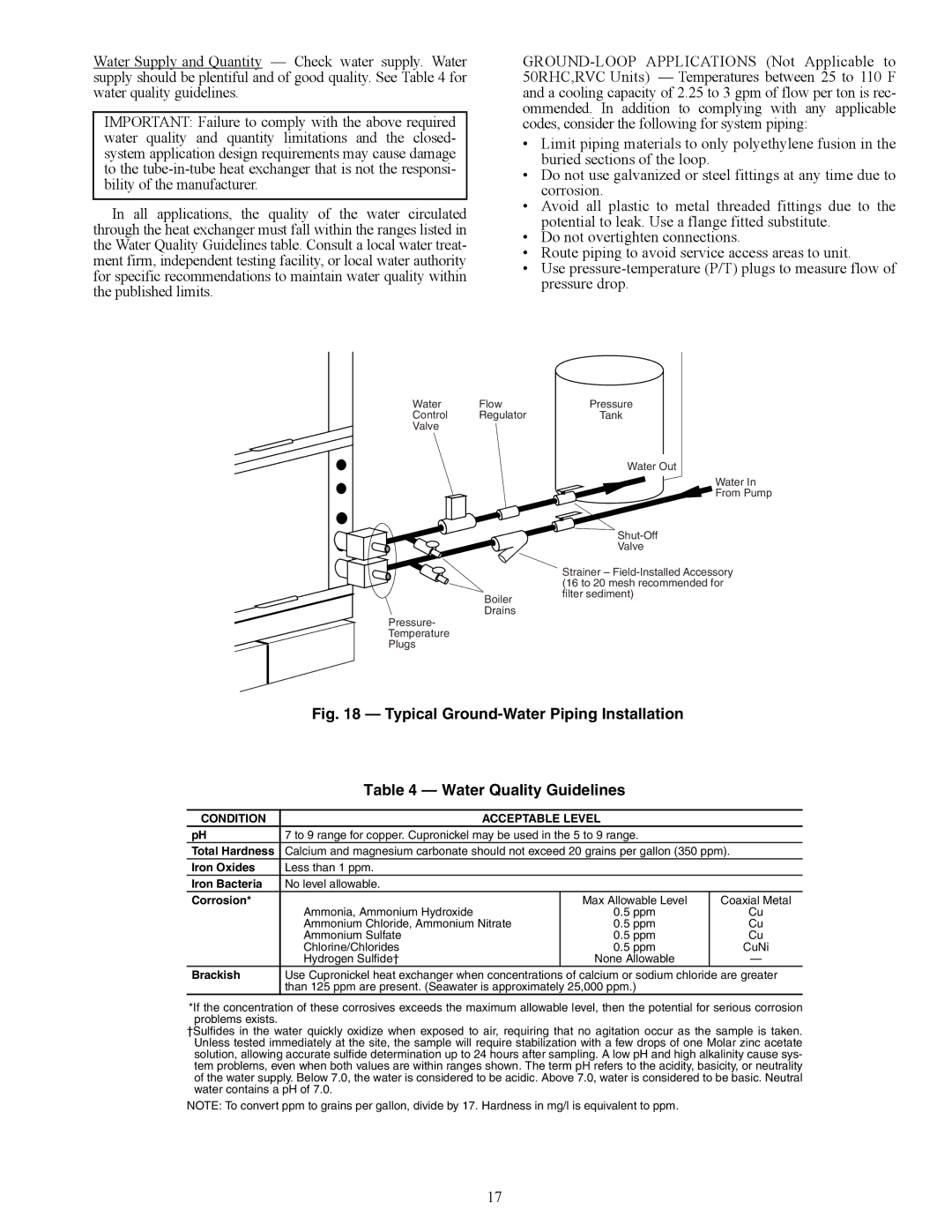

Fig. 18 — Typical Ground-Water Piping Installation

| Table 4 — Water Quality Guidelines |

| |

|

|

|

|

CONDITION | ACCEPTABLE LEVEL |

| |

pH | 7 to 9 range for copper. Cupronickel may be used in the 5 to 9 range. |

| |

Total Hardness | Calcium and magnesium carbonate should not exceed 20 grains per gallon (350 ppm). | ||

Iron Oxides | Less than 1 ppm. |

|

|

Iron Bacteria | No level allowable. |

|

|

Corrosion* |

| Max Allowable Level | Coaxial Metal |

| Ammonia, Ammonium Hydroxide | 0.5 ppm | Cu |

| Ammonium Chloride, Ammonium Nitrate | 0.5 ppm | Cu |

| Ammonium Sulfate | 0.5 ppm | Cu |

| Chlorine/Chlorides | 0.5 ppm | CuNi |

| Hydrogen Sulfide† | None Allowable | — |

Brackish | Use Cupronickel heat exchanger when concentrations of calcium or sodium chloride are greater | ||

| than 125 ppm are present. (Seawater is approximately 25,000 ppm.) |

| |

*If the concentration of these corrosives exceeds the maximum allowable level, then the potential for serious corrosion problems exists.

†Sulfides in the water quickly oxidize when exposed to air, requiring that no agitation occur as the sample is taken. Unless tested immediately at the site, the sample will require stabilization with a few drops of one Molar zinc acetate solution, allowing accurate sulfide determination up to 24 hours after sampling. A low pH and high alkalinity cause sys- tem problems, even when both values are within ranges shown. The term pH refers to the acidity, basicity, or neutrality of the water supply. Below 7.0, the water is considered to be acidic. Above 7.0, water is considered to be basic. Neutral water contains a pH of 7.0.

NOTE: To convert ppm to grains per gallon, divide by 17. Hardness in mg/l is equivalent to ppm.

17