|

|

|

|

|

|

|

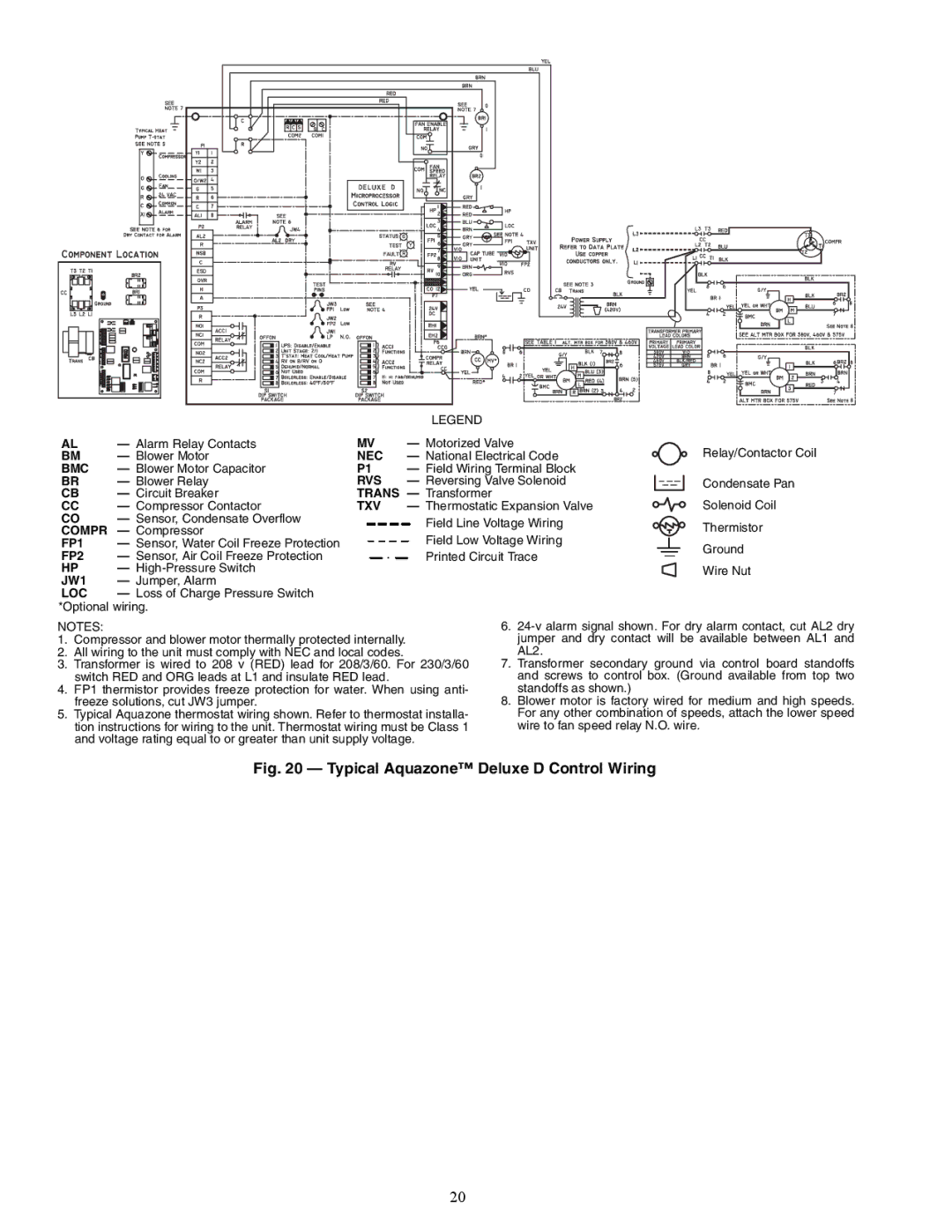

| LEGEND |

|

AL | — Alarm Relay Contacts | MV | — Motorized Valve | Relay/Contactor Coil |

BM | — Blower Motor | NEC | — National Electrical Code | |

BMC | — Blower Motor Capacitor | P1 | — Field Wiring Terminal Block |

|

BR | — Blower Relay | RVS | — Reversing Valve Solenoid | Condensate Pan |

CB | — Circuit Breaker | TRANS — Transformer |

| |

CC | — Compressor Contactor | TXV | — Thermostatic Expansion Valve | Solenoid Coil |

CO | — Sensor, Condensate Overflow |

| Field Line Voltage Wiring | Thermistor |

COMPR | — Compressor |

| ||

| Field Low Voltage Wiring | |||

FP1 | — Sensor, Water Coil Freeze Protection |

| Ground | |

FP2 | — Sensor, Air Coil Freeze Protection |

| Printed Circuit Trace | |

|

| |||

HP | — |

|

| Wire Nut |

JW1 | — Jumper, Alarm |

|

|

|

LOC | — Loss of Charge Pressure Switch |

|

|

|

*Optional wiring. |

|

| |

NOTES: | 6. | ||

1. | Compressor and blower motor thermally protected internally. |

| jumper and dry contact will be available between AL1 and |

2. | All wiring to the unit must comply with NEC and local codes. |

| AL2. |

3. | Transformer is wired to 208 v (RED) lead for 208/3/60. For 230/3/60 | 7. | Transformer secondary ground via control board standoffs |

| switch RED and ORG leads at L1 and insulate RED lead. |

| and screws to control box. (Ground available from top two |

4. | FP1 thermistor provides freeze protection for water. When using anti- |

| standoffs as shown.) |

| freeze solutions, cut JW3 jumper. | 8. | Blower motor is factory wired for medium and high speeds. |

5. | Typical Aquazone thermostat wiring shown. Refer to thermostat installa- |

| For any other combination of speeds, attach the lower speed |

| tion instructions for wiring to the unit. Thermostat wiring must be Class 1 |

| wire to fan speed relay N.O. wire. |

| and voltage rating equal to or greater than unit supply voltage. |

|

|

Fig. 20 — Typical Aquazone™ Deluxe D Control Wiring

20