Compressor — Conduct annual amperage checks to in- sure that amp draw is no more than 10% greater than indicated on the serial plate data.

Fan Motors — All units have lubricated fan motors. Fan motors should never be lubricated unless obvious, dry opera- tion is suspected. Periodic maintenance oiling is NOT recom- mended as it will result in dirt accumulating in the excess oil and cause eventual motor failure. Conduct annual dry opera- tion check and amperage check to ensure amp draw is no more than 10% greater than indicated on serial plate data.

Condensate Drain Cleaning — Clean the drain line and unit drain pan at the start of each cooling season. Check flow by pouring water into drain. Be sure trap is filled to main- tain an air seal.

Air Coil Cleaning — Remove dirt and debris from evap- orator coil as required by condition of the coil. A 10% solution of dishwasher detergent and water is recommended for cleaning both sides of the coil, followed by a thorough water rinse. Clean coil with a stiff brush, vacuum cleaner, or com- pressed air. Use a fin comb of the correct tooth spacing when straightening mashed or bent coil fins.

Condenser Cleaning —

Local water conditions may cause excessive fouling or pitting of tubes. Condenser tubes should therefore be cleaned at least once a year, or more often if the water is contaminated.

Proper water treatment can minimize tube fouling and pitting. If such conditions are anticipated, water treatment analysis is recommended. Refer to the Carrier System Design Manual, Part 5, for general water conditioning information.

Follow all safety codes. Wear safety glasses and rubber gloves when using inhibited hydrochloric acid solution. Observe and follow acid manufacturer’s instructions.

Clean condensers with an inhibited hydrochloric acid solution. The acid can stain hands and clothing, damage concrete, and, without inhibitor, damage steel. Cover sur- roundings to guard against splashing. Vapors from vent pipe are not harmful, but take care to prevent liquid from being carried over by the gases.

Warm solution acts faster, but cold solution is just as effec- tive if applied for a longer period.

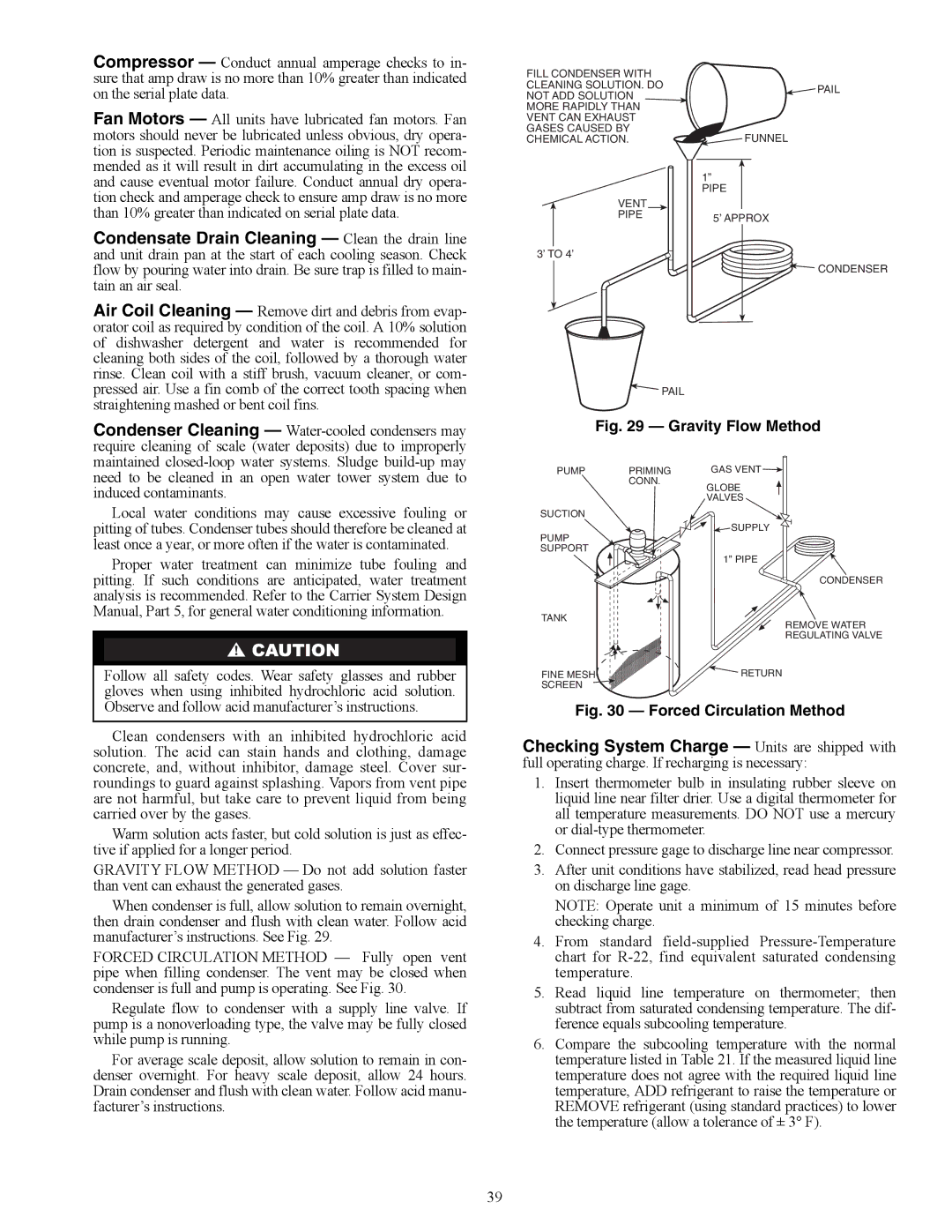

GRAVITY FLOW METHOD — Do not add solution faster than vent can exhaust the generated gases.

When condenser is full, allow solution to remain overnight, then drain condenser and flush with clean water. Follow acid manufacturer’s instructions. See Fig. 29.

FORCED CIRCULATION METHOD — Fully open vent pipe when filling condenser. The vent may be closed when condenser is full and pump is operating. See Fig. 30.

Regulate flow to condenser with a supply line valve. If pump is a nonoverloading type, the valve may be fully closed while pump is running.

For average scale deposit, allow solution to remain in con- denser overnight. For heavy scale deposit, allow 24 hours. Drain condenser and flush with clean water. Follow acid manu- facturer’s instructions.

FILL CONDENSER WITH |

| |

CLEANING SOLUTION. DO | PAIL | |

NOT ADD SOLUTION | ||

| ||

MORE RAPIDLY THAN |

| |

VENT CAN EXHAUST |

| |

GASES CAUSED BY | FUNNEL | |

CHEMICAL ACTION. | ||

| 1” | |

| PIPE | |

VENT |

| |

PIPE | 5’ APPROX | |

|

3’ TO 4’

CONDENSER

![]() PAIL

PAIL

Fig. 29 — Gravity Flow Method

PUMP | PRIMING | GAS VENT |

| CONN. | GLOBE |

|

| |

|

| VALVES |

SUCTION |

|

|

PUMP |

| SUPPLY |

|

| |

SUPPORT |

|

|

|

| 1” PIPE |

|

| CONDENSER |

TANK |

| REMOVE WATER |

|

| |

|

| REGULATING VALVE |

FINE MESH |

| RETURN |

SCREEN |

|

|

Fig. 30 — Forced Circulation Method

Checking System Charge — Units are shipped with full operating charge. If recharging is necessary:

1.Insert thermometer bulb in insulating rubber sleeve on liquid line near filter drier. Use a digital thermometer for all temperature measurements. DO NOT use a mercury or

2.Connect pressure gage to discharge line near compressor.

3.After unit conditions have stabilized, read head pressure on discharge line gage.

NOTE: Operate unit a minimum of 15 minutes before checking charge.

4.From standard

5.Read liquid line temperature on thermometer; then subtract from saturated condensing temperature. The dif- ference equals subcooling temperature.

6.Compare the subcooling temperature with the normal temperature listed in Table 21. If the measured liquid line temperature does not agree with the required liquid line temperature, ADD refrigerant to raise the temperature or REMOVE refrigerant (using standard practices) to lower the temperature (allow a tolerance of ± 3° F).

39