Models CHS-810, CHS-814, CHS-819, and CHS-824

CHS Tangential Feed Granulators

Date Manual Number UGG011/0504 Serial Numbers Model Numbers

Technical Specification

Table of Contents

4. Safety Instructions

Installation

Spare Parts List

Service

Wiring Diagram

i i l Ta b l e o f C o n t e n t s

A. Customer Service

11. Accessories, Overview

10. Layout

12. Transport and Storage

i v l Ta b l e o f C o n t e n t s

P u r p o s e o f t h e U s e r G u i d e . . . . . . . . . . . . . 1

I n t r o d u c t i o n

H o w t h e G u i d e i s O r g a n i z e d . . . . . . . . . . . . 1

AT T E N T I O N

Purpose of the User Guide

How the Guide is Organized

Your Responsibility as a User

AT T E N T I O N Read This so no One Gets Hurt

WARNING Voltage hazard

1 I n t r o d u c t i o n

This manual applies to the CHS series of Conair granulators

Technical Specifications

Technical Specifications

Technical Specifications l 2

2 - 2 l Technical Specifications

Hardened cutter housing

Performance characteristics

SPECIFICATION NOTES

G e n e r a l

Function Description

S a f e t y S y s t e m

Function Description

General

Function Description

models with a conveyor, the hopper is equipped with a conveyor belt. The conveyor can be equipped with a metal detector

Safety System

Safety Switch

Emergency Stop

Before Starting

Star Knob

3 - 6 l Function Description

Safety Instructions

4 S a f e t y I n s t r u c t i o n s

S a f e t y I n s t r u c t i o n s l 4

Electrical installation must only be done by a competent electrician

Safety Instructions

During maintenance, pull out the plug on the distribution box

If the rotor must be turned manually - do this with great care

DANGER! High voltage

DANGER! Cutting or pinch risk

DANGER! Be careful

4 - 4 l S a f e t y I n s t r u c t i o n s

I n s t a l l a t i o n l 5

I n s t a l l a t i o n

I n s t a l l a t i o n

Pre-Start Checks

Two Hours After First Start

The granulator should be connected by a competent electrician

Electrical Connection

Check the direction of rotation of the granulator motor

If any direction of rotation should be incorrect

Opening the hopper

Opening of Hopper, Screen Box and Granule Bin

Opening the screen box

screen box, switch both the main switch and

Closing the Screen Box, Granule Bin and Hopper

Close the screen box and install the granule bin

Close the hopper

There is a pinch risk during closing, be careful

5 - 6 l M a i n t e n a n c e

Maintenance

Operation and Daily Maintenance

Operation and Daily Maintenance l 6

S t a r t i n g a n d S t o p i n g

Operation and Daily Maintenance

Starting and Stopping

6 - 2 l Operation and Daily Maintenance

Daily Inspection

Inspection

Weekly Inspection

Monthly Inspection

Cleaning

Switch “Off” both the main switch and the switch on the granulator

6 - 4 l Operation and Daily Maintenance

Re-install after cleaning

Fault-Finding

6 - 6 l Operation and Daily Maintenance

The granulator does not start

Operation and Daily Maintenance l 6

6 - 8 l Operation and daily maintenance

S e r v i c e

Changing the knives

Service

Removing the knives

Changing the knives

Installing the Knives

First install the rear, fixed knife

Install the rotating knives

6 Install screws A with washers B, and tighten so that they hold

Then install the front, fixed knife

Sharpening Knives - Granulators with Open Cutter

Sharpening Knives

Grind the cutting angle of the knives to

V-Belts, Inspection, and Adjustment

Transmission

The granulator is driven by 3 V-belts Checking the V-belts

V-belt Adjustment

Transmission continued

Lubrication

Cutter Housing

7 - 1 0 l Service

Cutter Pulley/Motor Pulley

Installing

Removal

Cutter Pulley

7 - 1 2 l Service

S a f e t y

Spare Parts List

Ordering Spare Parts

Spare Parts List

Cutting Chamber

Art. no

Description

Art. no

Staggered Rotor

Description

8 - 4 l S p a r e P a r t s L i s t

List

Open Rotor

Spare

Parts

Knives, Open Cutter

Knives

8 - 6 l S p a r e P a r t s L i s t

Art. no

Screen

Screen Box

8 - 8 l S p a r e P a r t s L i s t

Granule Bin Manual Optional

8 - 1 0 l S p a r e P a r t s L i s t

Vaccum Suction /Blower F-7/F-15

Pos Qty

Art. no

Hopper

8 - 12 l S p a r e P a r t s L i s t

Hopper - Noise encapsulated machine with with Conveyor

S p a r e P a r t s L i s t l 8 - 1

Hopper Device

8 - 14 l S p a r e P a r t s L i s t

Sound Cabin

8.17 Enclosure/Body

8 - 1 6 l S p a r e P a r t s L i s t

Safety

9 Wiring Diagram

Wiring Diagram

W i r i n g D i a g r a m

W i r i n g D i a g r a m l 9

Wiring diagram

Relay functions and normal settings

Current Sensing Relay

Default setting for this granulator

Connection

Relay Setting

Example

9 - 6 l W i r i n g D i a g r a m

1 0 Layout

L a y o u t

1 0 - 2 l L a y o u t

Layout

1650mm64.96in

1490mm58.66in

27.56in.700mm

1790mm70.47in

1 0 - 4 l L a y o u t

1 1 Accessories

A c c e s s o r i e s

Ordering Spare Parts

A c c e s s o r i e s

Pre - Setting of Rotating Knives, Granulator with Open Cutter

Setting Up the Knives

Installation of Pre-Set Knives

Tighten the fastening screws, tightening torque 162.26lb-ft 220 Nm

Installation

Third Fixed Knife

Sharpening

Band Conveyor

Safety

Electrical Connection

The band conveyor should be connected up by an authorised electrician

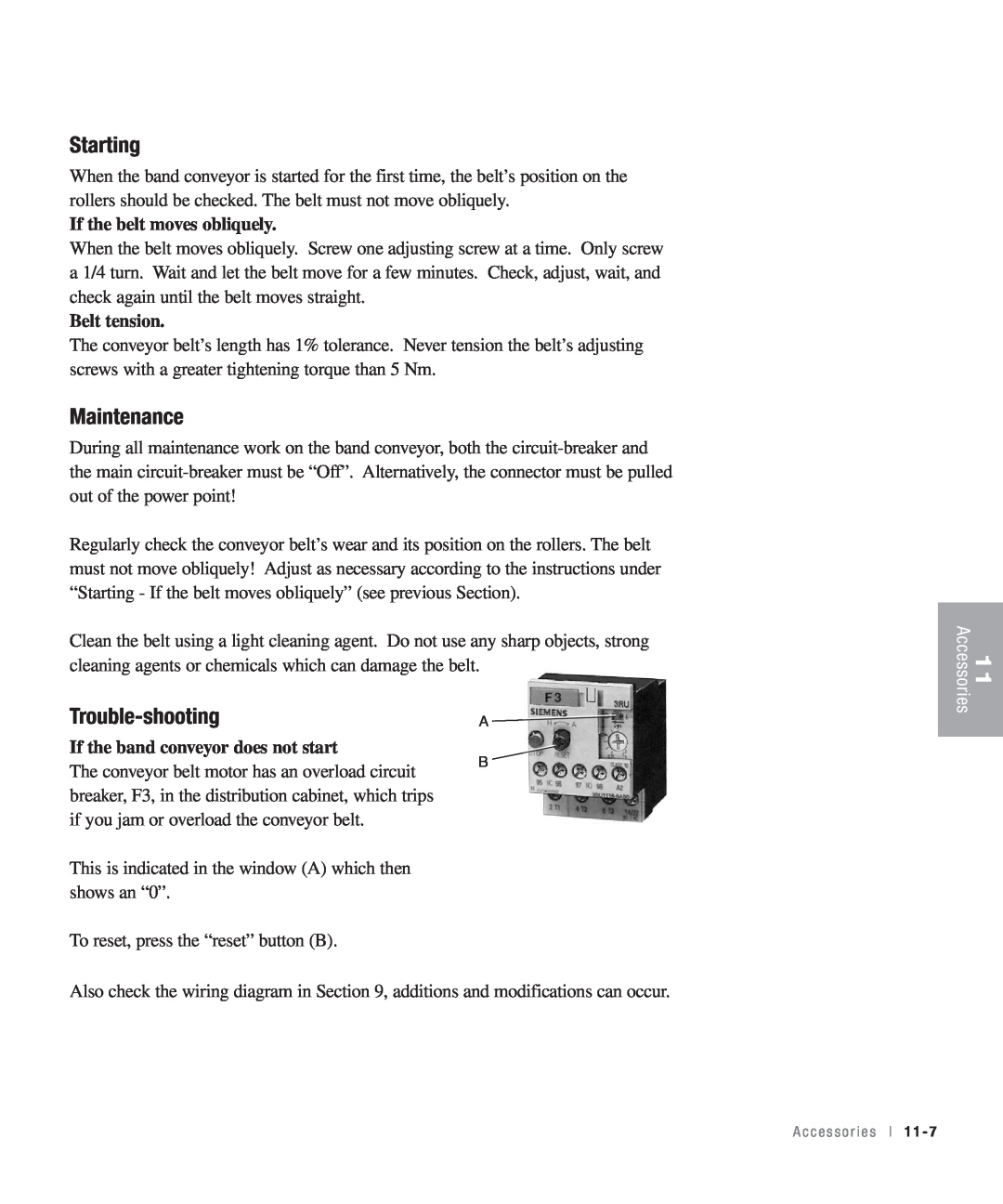

Trouble-shooting

Maintenance

Starting

If the belt moves obliquely

11 - 8 l A c c e s s o r i e s

Spare Parts for the Band Conveyor

U n p a c k i n g a n d C h e c k i n g

Transport and Storage

Transport and

Storeage

Lifting and Transport to Place of Use

Transport and storage

Unpacking and Checking

Positioning in Place of Use

Long-Term Storage/Conservation

Storage

1 2 - 4 l T r a n s p o r t a n d S t o r a g e

We’re Here to Help

How to Contact Customer Ser vice

Before You Call

From outside the United States, call

Performance Warranty

Equipment Guarantee

Warranty Limitations

A - 2 l A p p e n d i