Page

Page

Welcome to the World of Cub Cadet Yanmar Tractor

INTRODUCTION

Sc2400 Operator’s Manual

TABLE OF CONTENTS

11-1

9. POWER TAKE OFF PTO

10-1

11.HYDRAULIC SYSTEM

12-1

13.MAINTENANCE

TABLE OF CONTENTS

12.TIRES, WHEELS AND BALLAST

15.SERVICING THE ELECTRICAL SYSTEM

16.STORAGE

17.TROUBLESHOOTING

18.INDEX

1. About This Manual

1.SAFETY PRECAUTIONS

1.SAFETY PRECAUTIONS

1. SAFETY PRECAUTIONS

2. Safety-AlertSymbols

DANGER

NOTICE

3. Precautions before Operating Your Tractor

1. Starting Your Tractor

4. Safe Practices for Operating Your Tractor

2. Working with Your Tractor

3. Considerations for Safety of Children

DO NOT

5. Operating Your Tractor on Slopes

7. Safe Practices for Parking Your Tractor

6. Traveling on a Road

9. Using the 3-PointHitch

8. Operating the Power Take Off PTO

11. Safe Practices for Servicing Your Tractor

Sc2400 Operator’s Manual

1-11

12.Understanding the Tractor Safety Decals

Safety-AlertSymbols

Care of DANGER, WARNING and CAUTION Decals

BCY1A7880-65620

TO AVOID INJURY OR DEATH

DANGER

ACY1A8160-65300

C CY124764-44810

DANGER/POISON ENGLISH

D CY1A8160-51520

NUAL

4.DO NOT USE WHEN WET

12V DC OUTLET

TORS

HCY1A7880-85170

GCY1A7880-65350

ICY1A7880-85180

KCY1A8160-65310

AVOID INJURY FROM PTO

TO AVOID INJURY

JCY198220-65621

2.SERVICING THE TRACTOR

2.SERVICING THE TRACTOR

1. Specifications Table

3.SPECIFICATIONS

3.SPECIFICATIONS

3. SPECIFICATIONS

2. Traveling Speeds

4.IMPLEMENT CAPACITIES

4.IMPLEMENT CAPACITIES

5.NAMES AND FUNCTIONS OF COMPONENTS

1. Appearance

98 20

19 18 17

25 24

2. Operator Station Controls

21 20 19 18 17 16 15

12 3 4 5 6 7 8 9 10

1 Tachometer

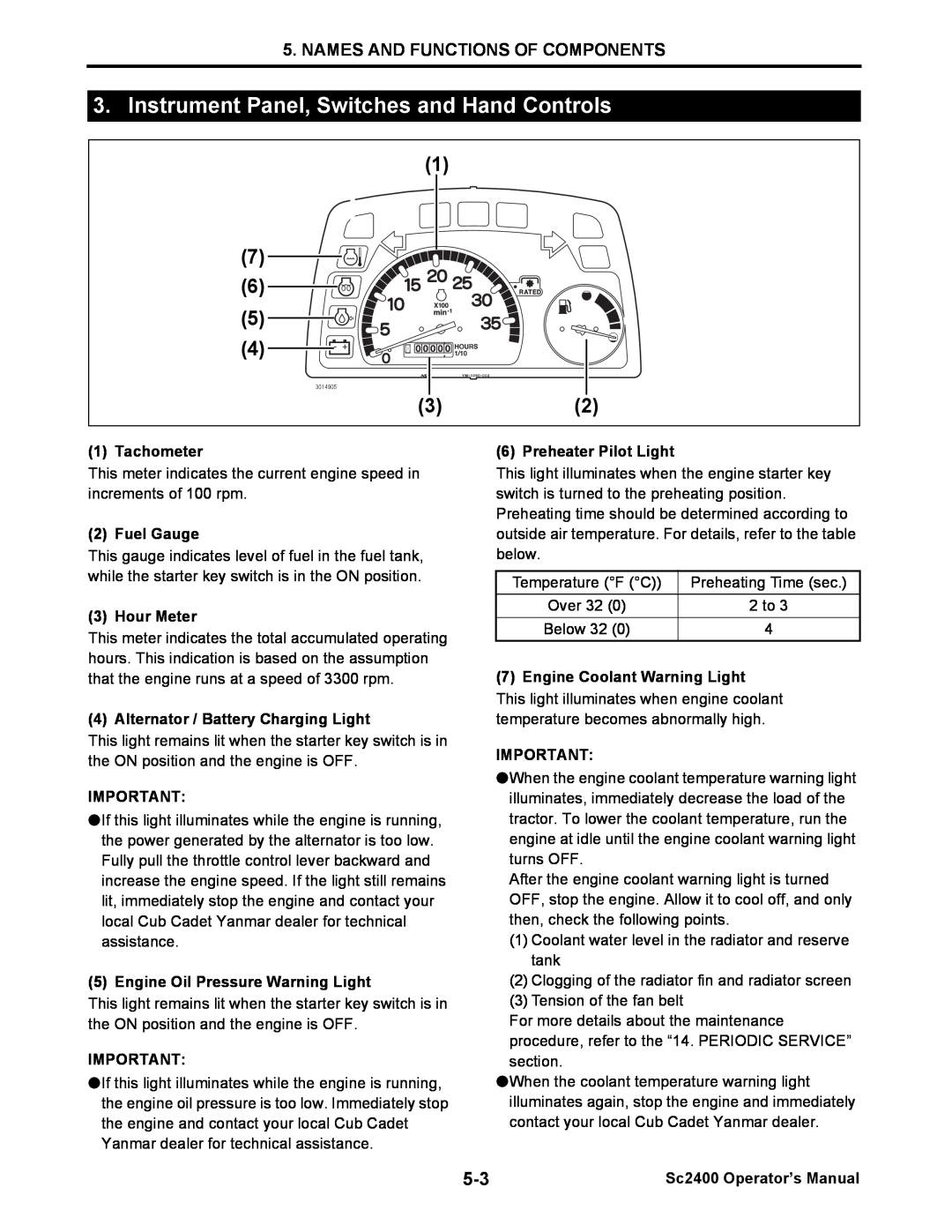

3.Instrument Panel, Switches and Hand Controls

1 7 6 5 4

4 Alternator / Battery Charging Light

a b c A

9Hazard Lights Button Switch

3.Routine Check

2. Precautions before the Operation

6.PRE-OPERATIONCHECK

1.Pre-OperationCheck

1. Starting the Engine

7.OPERATING THE ENGINE

7.OPERATING THE ENGINE

Avoid injury

2. Sit on the seat Adjusting the Operators Seat

Fastening the Retractable Seat Belt

7. OPERATING THE ENGINE

IMPORTANT: Avoid damage

5.Set the range shift lever to the Slow position

6.Turn off the Power Take Off PTO switch

9. Set the throttle control lever about

Checking the Lights on the Instrument Panel

Warming Up the Engine in Cold Weather

13.After the engine has started, warm up

IMPORTANT: Avoid starter damage

2. Stopping the Engine

3. Restarting a Stalled Engine

Accident Hazard

8.OPERATING THE TRACTOR

8.OPERATING THE TRACTOR

1. Operating a New Tractor

Hazard Lights

2. Operation of the Tractor

3. Start the engine

Throttle Control Lever

7. Disengage the parking brake

Disengaging the Cruise Control

Engaging the Cruise Control

3. Stopping Travel of the Tractor

Applying the Parking Brake

4.Parking the Tractor

Releasing the Parking Brake

Do not attempt to turn with the differential lock

5. Safe Practices for Operation

Avoid injury. To prevent the tractor from

overturning

8-11

2. Safely Driving the Tractor on Roads

8-12

8-13

8-14

4. Transporting the Tractor on a Trailer

Close the fuel shut-offvalve

5. Operating on Slopes

When exiting a ditch, deep mud or traveling on

8-15

Steep Downhill

Uphill / Downhill

8-16

7. About the 12V DC Outlet

6. About the Power Steering

8-17

Be careful to avoid injury

9.POWER TAKE OFF PTO

1. Operating the Power Take Off PTO

9.POWER TAKE OFF PTO

9. POWER TAKE OFF PTO

Rear- Power Take Off PTO

Mid- Power Take Off PTO

Engaging the Power Take Off PTO

c b A a

a b A

Disengaging the Power Take Off PTO

Sc2400 Operator’s Manual

10. 3-POINTHITCH

1. Adjusting the 3-PointHitch

10. 3-POINTHITCH

Hitch

Right Lift Link

Top Link

Sway Link

1. 3-PointHitch Control System

11.HYDRAULIC SYSTEM

11.HYDRAULIC SYSTEM

11-2

Hydraulic Flow Control / Stop Knob

11. HYDRAULIC SYSTEM

pressure Use a piece of cardboard to detect leaks

2.Controlling the Implement Control Valve Option

11-4

Implement Control Lever Option

Implement Lock Lever Option

b a c f d e

11-5

Connecting the Implement Hydraulic Hoses

1. Tires

12.TIRES, WHEELS AND BALLAST

12.TIRES, WHEELS AND BALLAST

12. TIRES, WHEELS AND BALLAST

Inflation Pressure

Wheel Bolt Tightening Torque

12-2

Front End Weights Option

2.Ballast

NEVER overload the tires

IMPORTANT: Avoid damage

1.Maintenance Check List

13.MAINTENANCE

13.MAINTENANCE

13. MAINTENANCE

Lubricants

13-3

3.Replacement Parts

1.Technical Document

2. Parts

NEVER inhale the emission gas

14.PERIODIC SERVICE

Warranty and Repair of the Engine

14. PERIODIC SERVICE

Closing the Hood

1. Opening / Closing the Hood

Opening the Hood

A a b

Bio-dieselFuels

2.Daily Checks

IMPORTANT: Be careful to avoid damage

Keep the fuel away from an open flame or sparks

EPA REGULATION

14-5

Checking the Engine Oil Level

a b B

Checking the Transmission Oil Level

14-6

BC B

Cleaning the Radiator Cooling Fins and Screen

Checking the Radiator Hoses and Clamps

BA B

IMPORTANT Avoid damage

ALWAYS shut the engine down and allow it to cool

Checking the Cooling System

BA a b

14-9

14-10

Checking the Fuel Line

Checking the Intake Air Hoses and Clamps

A A A

To avoid personal injury, do as follows

Checking the Safety Interlock System

1. Power Take Off PTO Safety Switch

14-11

5. Seat Safety Switch

2. Parking Brake Safety Switch

3. Drive Pedal Safety Switch

4. Drive Pedal and Seat Safety Switch

14-13

Checking and Adjusting the Brake

14-14

Checking the Wheel Bolt Tightening Torque

Checking the Inflation Pressure

a b c

14-15

A Tie-rodrubber boots

P3014960

ALWAYS wear protective goggles and gloves

1. Power Steering Hoses

Checking the Hydraulic Hoses

14-16

2. Implement Control Valve Hoses

4.Every 50 Hours

3.First 50 Hours

When the oil level is low

Before servicing, stop the engine

14-19

NEVER smoke while handling the fuel

Keep the fuel away from open flames or sparks

Adjusting the Fan Belt

All other conditions

14-21

IMPORTANT: Prevent damage

Extremely wet or muddy conditions

4.Lubricating the 3-PointHitch

3. Lubricating the Seat Slide Rails

14-22

Engine crankcase

5. Every 100 Hours

Keep the fuel away from open flames or sparks

14-25

10.Reinstall the air cleaner element

hot, stay clear of the hot engine oil and other

6.Every 200 Hours

When draining away the engine oil that is still

14-27

7.Every 300 Hours

14-29

Front Axle Case Oil

8.Every 500 Hours

14-31

The following coolants are recommended

9.Every 1000 Hours

14-33

14-34

2. Flushing the Cooling System

14-35

Adjusting the Engine Valve Clearance

Changing the Coolant

Checking the Fuel Injection Pump

Replacing the Radiator Hoses and Clamp

10.Every 1 Year

11.Every 2 Years

Replacing the Air Cleaner Element

15.SERVICING THE ELECTRICAL SYSTEM

1.Battery

15.SERVICING THE ELECTRICAL SYSTEM

Wear protective goggles and gloves

NEVER smoke near the battery

E F C D A BE

Inspecting the Battery

Removing and Installing the Battery

1. Removing the Battery

Cleaning the Battery and Terminals

2. Installing the Battery

15-4

15-5

Using a Booster Battery

2. Fuses

the bulb carefully when replacing it

3.Bulb

may shatter. Wear protective goggles and handle

15-8

Replacing the Work Light Bulb

Replacing the Tail Light Bulb

Replacing the Turn Signal / Hazard Lights Bulb

15-9

15-10

4.Headlights

Adjusting the Headlights

Replacing the Instrument Panel Light Bulb

1. Safe Practices for Storage

16. STORAGE

16. STORAGE

IMPORTANT: Be very careful to avoid damage

2. Preparing the Fuel and Engine for Storage Fuel

Engine

16-2

2.Preparing the Stored Tractor for Operation

it is not powerful

17.TROUBLESHOOTING

1. How to Use the Troubleshooting Table

17.TROUBLESHOOTING

The machine

17. TROUBLESHOOTING

The engine

overheats

function correctly

Brake does not

Steering does not

18. INDEX

18. INDEX