HARSFEN0602ElmoHARmonicaSoftwareManual | PRELIMINARYDRAFT |

At that very instance the Hall sensors read the electrical angle accurately.

After the first Hall sensor switch, the commutation is kept accurate by updating the commutation counter incrementally using the shaft position sensor.

9.3.3.2Detecting commutation errors (loss of feedback)

After commutation by the encoder starts, there exist two sources for the electrical angle measurement. There is the

The digital Hall sensor readout defines a range in which the high resolution calculated angle should reside. Deviating from this range by more than few degrees results in declaring a commutation error and automatic motor shut down.

The allowed deviation is increased in higher speeds, since there the sensor and the calculation delays contribute a significant matching error.

The most common causes for commutation loss are:

-A slit in the encoder disk is clogged with dirt. When this happens, an encoder of 4000 counts/rev may count for example 3999 counts/rev. After enough revolutions, the cumulative error is large.

-Speed to fast relative to the defined encoder filer, and encoder pulses are lost.

-An interpolator derives the encoder A/B pulses. Some interpolators send, from time to time, pulse batches of much higher frequency then the motor speed. Avoid using the encoder filter with interpolators even if you think that the motor speed shall be slow enough.

9.3.4Parameterization of the commutation and the commutation sensors

9.3.4.1Winding order

The Harmonica has three motor connection pins, named A, B, and C.

The pin names are not rigidly tied to their actual role. The harmonica can define internally which motor phase is connected to which output pin. The parameter CA[25] controls the connection:

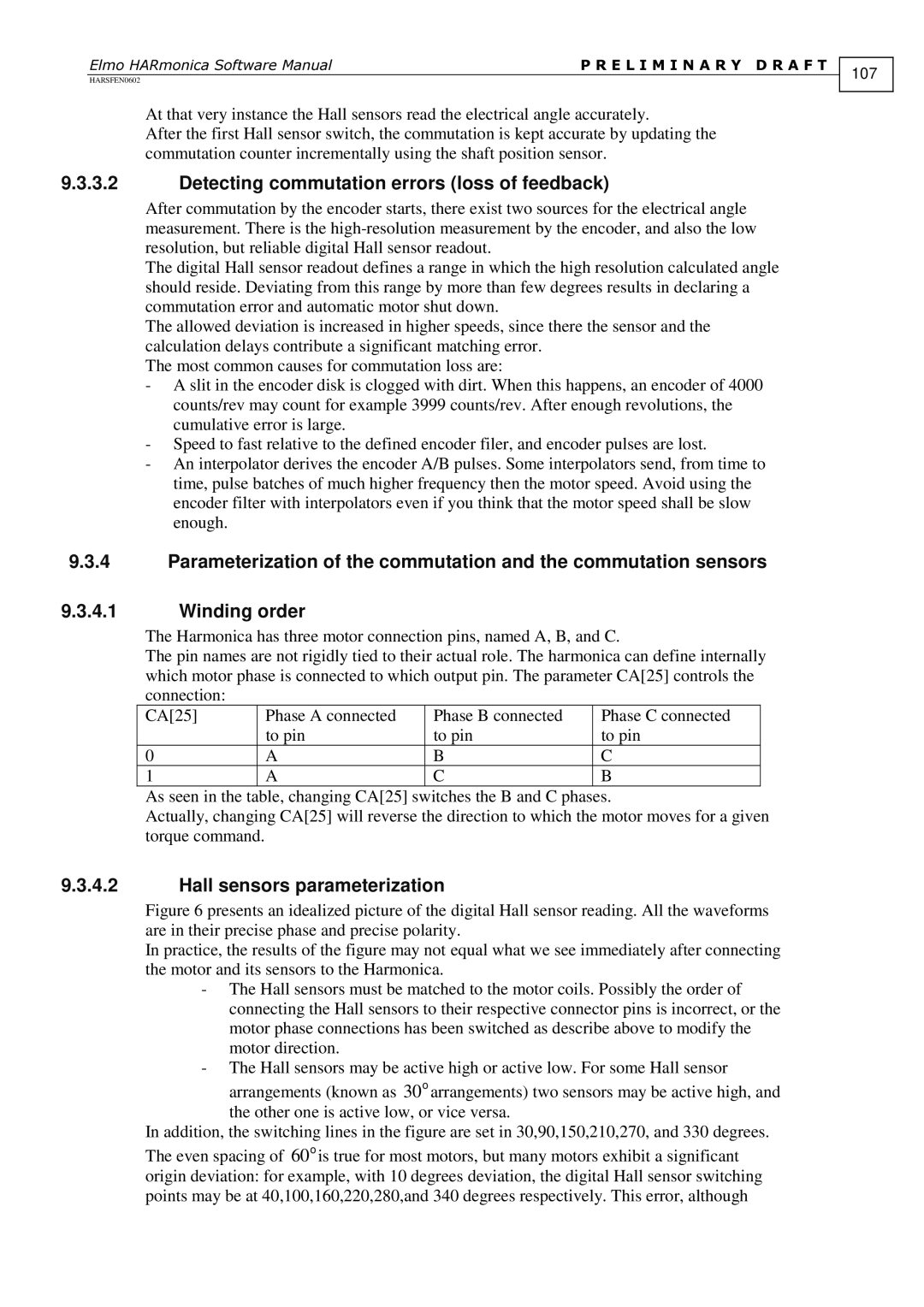

CA[25] | Phase A connected | Phase B connected | Phase C connected |

| to pin | to pin | to pin |

0 | A | B | C |

1 | A | C | B |

As seen in the table, changing CA[25] switches the B and C phases.

Actually, changing CA[25] will reverse the direction to which the motor moves for a given torque command.

9.3.4.2Hall sensors parameterization

Figure 6 presents an idealized picture of the digital Hall sensor reading. All the waveforms are in their precise phase and precise polarity.

In practice, the results of the figure may not equal what we see immediately after connecting the motor and its sensors to the Harmonica.

-The Hall sensors must be matched to the motor coils. Possibly the order of connecting the Hall sensors to their respective connector pins is incorrect, or the motor phase connections has been switched as describe above to modify the motor direction.

-The Hall sensors may be active high or active low. For some Hall sensor arrangements (known as 30oarrangements) two sensors may be active high, and

the other one is active low, or vice versa.

In addition, the switching lines in the figure are set in 30,90,150,210,270, and 330 degrees.

The even spacing of 60ois true for most motors, but many motors exhibit a significant origin deviation: for example, with 10 degrees deviation, the digital Hall sensor switching points may be at 40,100,160,220,280,and 340 degrees respectively. This error, although