HARmonica Software Manual

Elmo Motion Control Inc

USA

HARSFEN0602ElmoHARmonicaSoftwareManual

HARSFEN0602ElmoHARmonicaSoftwareManual

Program execution

Preliminary

115

HARSFEN0602ElmoHARmonicaSoftwareManual

Language

100

HARSFEN0602ElmoHARmonicaSoftwareManual

About This Manual

Scope

Relevant documentation

Glossary

Harmonica

Related Software

Units

Position units

Can EDS

Speed and acceleration units

Current and torque

Internal Units and Conversions

Power DC voltage

Speed

Electrical angle

Peripherals

A/D converter

Digital inputs

Digital output

Communication With the Host

General RS232 Communications

1 RS232 Basics

Description

Errors and exceptions in RS232

Echo

Background Transmission

CANopen Communication

ElmoHARSFEN0602HARmonicaSoftwareManual Preliminarydraft

Interpreter Language

Command line

Expressions And Operators

Numbers

Mathematical And Logical Operators

Operator details

XOR

Addition

Subtraction

Multiplication

Division

Bitwise not

Bitwise or

Bitwise

Logical Equality

Logical Greater than or equal

Logical Less than

Logical

Logical or

Logical not

Unary Minus

Bitwise Left Shift and Right Shift operators

Mathematical functions

Expressions

Simple Expressions

Assignment Expressions

User variables

Built-in Function Calls

Time functions

Example ca1 =

User Function Calls

Comments

Harmonica User Programming Language

User Program Organization

Common

Line and Expression Termination

Line Continuation

Limitations

Expressions And Operators Numbers

General rules for operators

Expressions Simple Expressions

Syntax

System Commands

Built-in Function Calls

Program Flow Commands

Labels Entry points

For iteration

#@LABELNAME

XQ ##LOOP2

While iteration

Infiniteloop

Until iteration

While expression

Wait iteration

If condition

Switch selection

OFF

Break

Functions Function definition

Syntax break

Function is absent

Dummy variables

Count of output variables

Automatic variables

STD

Mean

Global variables

Jumps

Functions and The Call Stack

##LABEL1

##LABEL2

Return

Killing The Call Stack

Automatic subroutines List Of Automatic Routines

##STARTNEW

#@AUTOI1

Autoexec

Autoer

Autostop

Autobg

Automatic Routines Arbitration

Automatic Subroutine Mask

##LOOP

#@AUTOI3

#@TESTPARS

MI=MI8

Compilation Error List

Program Development and Execution

Editing a Program

Compilation

HARSFEN0602ElmoHARmonicaSoftwareManual

Asusid@elmo.co.il

Preliminarydraft

Preliminarydraft

Preliminarydraft

Preliminarydraft

Asusid@elmo.co.il

Downloading and Uploading a Program

#@AUTOEXEC

Assisting Commands For Down/Upload LPN command

Binary data

Examples

CP command

CC command

Downloading a Program DL command

Program downloading process

Uploading a Program LS command

Program execution

Initiating a Program

Halting and resuming a program

XQ##TASK1

Automatic program running with power up

DB command

Save to Flash

Clear user program from Flash

Machine status

Program status

DB##MS

DB##PSN

Setting and clearing break points

Continuation of the program

Single step

Run to Cursor

Step Over

Step

Step Out

Setting stack

Getting stack entries

Getting call stack

View of global variables

View of local variables

HARSFEN0602ElmoHARmonicaSoftwareManual

Virtual Machines

Virtual Machine registers

Call Stack During Function Call

Data types

Usrsubj

Op code structure and addressing modes

Short reference

REM

Rsltand

Rsltor

Not

Alphabetic reference

Bitwise and Operator

Purpose

Algorithm

CMP Compare

DIV Divide

EOL End Of Line

Foritr for Loop Iteration

Algorithm itr iterator

Freevac Free Virtual Machine

For Bitwise or Operator

Getcomm Get Command

JMP Jump

Jmpeol Jump

Jmplabel Jump to the label

JNZ Jump Not Zero

Jnzeol Jump Not Zero

JZ Jump If Zero

Jzeol Jump If Zero

Link

MLT Multiply

MOV Assignment Operator =

Not Bitwise not Operator

REM Reminder

Rslta Relational Operator

Rsltae Relational Operator =

Rsltand Logical and Operator

Rsltb Relational Operator

Rsltbe Relational Operator =

SP SP

Rslte Relational Operator ==

Rsltne Relational Operator !=

Setcomm Set Command

Rsltor Logical or Operator

SHR Shift Right

SHL Shift Left

Spadd

Syssubj Jump To System Subroutine

Unarynot Logical not Operator

Usrsubj jump To User Subroutine

Usrsubrt Return from user subroutine

OP2

XOR Bitwise XOR Operator

Recorder

BG,BT

ILN

RPN

Signal mapping

Signal Signal Name Command Length Description Type

Defining the set of recorded signals

Programming the length and the resolution

Example The commands RV1=5RV2=1RC=3

Trigger events and timing

Trigger delay

Slope and window trigger types

Preliminary

Definition

100

Launching the recorder

Uploading recorded data

101

Preliminary Draft

Byte Number Value Type

103

Commutation

General

Brush DC motors

104

Bldc commutation policy

Mechanical and electrical motion Figures are missing

Commutation sensors

Rotor Magnetic field sensors

106

Shaft Angle Sensors

Detecting commutation errors loss of feedback

107

Hall sensors parameterization

108

Encoder parameterization

109

Commutation search General

Selecting the parameters

110

Method limitation

Protections

111

Continuous Vs. Six-Steps commutation

112

Continuous commutation

113

Winding shapes

114

Loading the commutation table

115

Current controller

116

ID = I hθ + 90 + Ib hθ + 210 + Ic hθ +

117

Peak/Continuous current limit selection

Torque command filter

118

119

32768

120

PI current controller

121

Current amplifier protections

122

Torque control Unit mode

123

Unit Modes

Speed mode Unit mode

11.2.1The software speed command

124

Speed Profiling using JV, AC and DC

125

11.2.2The auxiliary speed command

126

127

Stop management

RLS,FLS

Stepper mode Unit mode

128

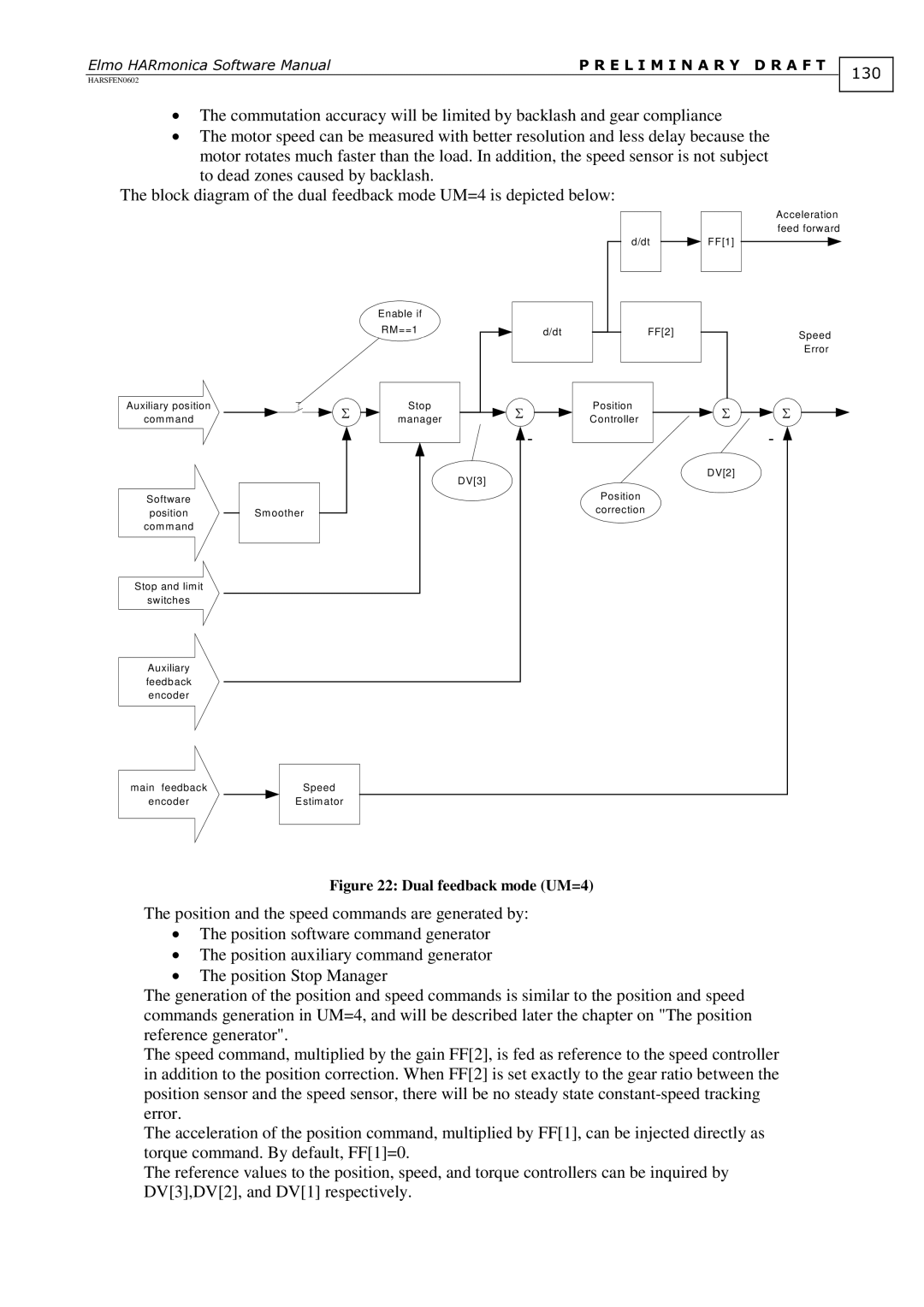

Dual feedback mode UM=4

129

Dual feedback mode UM=4

130

Single feedback mode UM=5

131

12.1.1Switching Between Motion Modes

132

Position reference generator

Software reference generator

12.1.3The Idle Mode and Motion Status

133

12.1.2Comparison of the PT and the PVT interpolated modes

134

12.1.4Point-To-Point PTP Basic Point-To-Point

135

Example

136

More Complicated PTP Motions

137

Example On-The-Fly Change of The Position Target

138

Jogging

Example On the fly mode switching

139

Example Simple jogging

140

141

Vt = 3at − t0 2 + 2bt − t0 + c

142

Ifference Counts Msec 500 1000 1500 2000 2500

143

144

QP… QV… QT…

145

Motion Management

PVT Decisions Flow Chart

146

Mode Termination

PVT Motion Using can

147

148

PVT Motion Programming Message

149

Underflow

Programming Sequence for The Auto Increment PVT Mode

Parameters of The PVT Motion Mode

150

151

152

PT Motion What Is PT

153

Interpolation Mathematics

PT Motion Programming The Basic Mode

154

Flow chart of the basic PT mode is depicted below

155

PT Motion Using can

156

PT Motion Programming Message

Programming Sequence for The Auto Increment PT Mode

157

Parameters of The PT Motion Mode

158

159

External Position Reference Generator

160

External position reference generator

161

Xt = 10000 ⋅ cos2πt + ct

162

Ecam

163

164

165

Dividing Ecam table into several logical portions

On the fly Ecam programming using can

166

167

Initializing the external reference parameters

Jump-Free Motor Starting Policy

168

Stop management 12.3.1General description

169

Stop Manager Internals

VHN,VLN

XM,YM

Right Limit Switch Marked as 3 in the Figure

Forward Limit Switch Marked as 4 in the Figure

170

Rate and Acceleration Marked as 5 in the Figure

171

Position output of the stop manager

172

Sensors, I/O, and Events

Modulo counting Modulo Counting

173

Digital Outputs

174

Events, and response methods

Manual inquiry

Periodical Inquiry

Homing and Capture What Is Homing?

175

Automatic routines

Real time Motion management, Homing, Capture, and Flag

176

Homing Programming

Homing the auxiliary encoder

On the fly position counter updates

13.5.5A homing with home switch and index example

177

Switches location

178

179

Example Double homing corrects backlash offsets

180

Capturing

Limits, Protections, Faults, and Diagnosis

181

182

Current limiting

VLN

183

Speed Protection

184

Position Protection

Enable switch

185

Limit switches

Connecting an external brake

186

When the motor fails to start

Motion faults

187

188

Diagnosis Monitoring motion faults

14.9.2Inconsistent setup data

189

Polling the amplifier status

Sensor faults Motor cannot move

190

14.9.3Device failures, and the CPU dump

Commutation error is static i.e. Does not change in time

191

Commutation is lost General

Reasons and effect of incorrect commutation

Detection of Commutation Feedback Fault

192

Commutation is drifting i.e Changes in time

Double sensor systems

193

Controller

KPN

Speed Control 15.2.1Block diagram

194

Not found

195

Parameters of the Speed Controller

Position Controller 15.3.1Block Diagram

196

197

Parameters of the Position Controller

198

High Order Filter Block Types

Double lead block Block type=12

Fist order block Block type=14

199

Second order block Block Type=15

Scheduled Double lead block Block type=22

200

User Interface

An Example

201

Gain-Scheduling Algorithm

202

Automatic Controller Gain-Scheduling

203

KP = SpeedKpTable k KI = SpeedKiTable k

Table of Contents TOC

204

Appendix a The Harmonica Flash Memory Organization

Main partitions

Contents of Text1

Contents of Text2

Contents of Text3

Contents of Text4-Text7

206

Contents of Text8

Contents of Text9

207

208

Autostop Autobg Autorls

Autoena AUTOI1

AUTOI5

209

210

TOC

Compilation Done Flag

Text Backup & Compiler data segment

Function Symbol Table

211

Virtual Machine Code Segment

Variable Symbol Table

212

Automatic Routines Table

213

Appendix B Harmonica Internals

Software Structure

17.1.1The Initialization block

214

Idle Loop

215

Idle loop

216

Converter

Converter Call

Algorithm

217

18.5 Examples

JP##LABEL

JS##LABEL Label

218

![]()