Instruction Manual

Hazardous Area Oxymitter DR

This check valve or blocking valve is to prevent breathing of the calibration gas line and subsequent flue gas condensation and corrosion.

g.Upgrading the Hazardous Area Oxymitter DR

The Hazardous Area Oxymitter DR can be easily upgraded to a full Oxymitter 4000 or 5000. This provides an economi- cal upgrade path for users looking to pre- serve their probe investment upon the eventual failure of the signal conditioning electronics. Upgrading the Hazardous Area Oxymitter DR to a full Oxymitter 4000 or 5000 requires only the addition of a small electronics package to the exist- ing termination housing of the Hazardous Area Oxymitter DR probe. The converted unit will be a full Oxymitter 4000 or 5000 Oxygen Transmitter with the capability of providing a

1-3 PROBE OPTIONS

a.Abrasive Shield Assembly

The abrasive shield assembly, Figure

b.Flame Arrestor Ceramic Diffusion Assembly

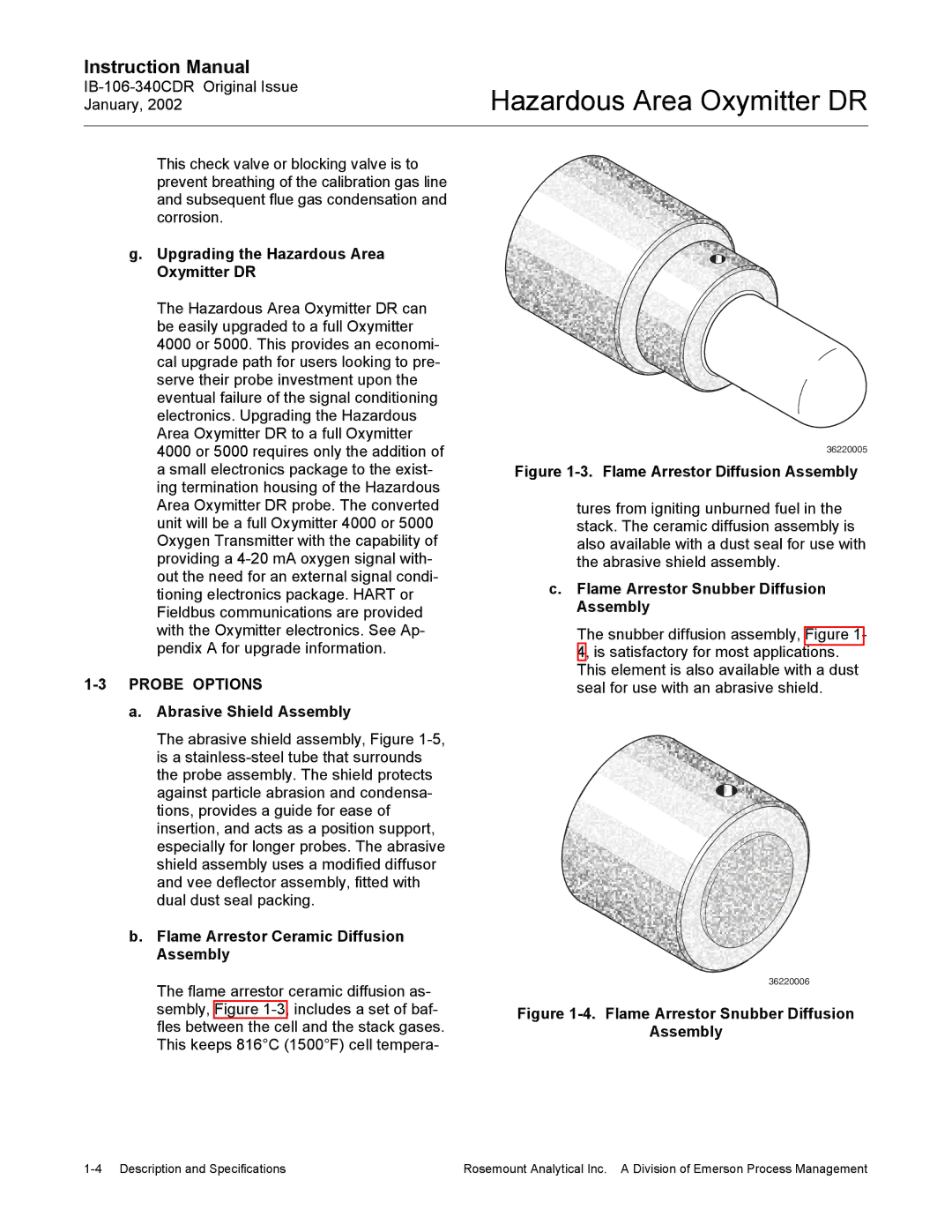

The flame arrestor ceramic diffusion as- sembly, Figure

36220005

Figure 1-3. Flame Arrestor Diffusion Assembly

tures from igniting unburned fuel in the stack. The ceramic diffusion assembly is also available with a dust seal for use with the abrasive shield assembly.

c.Flame Arrestor Snubber Diffusion Assembly

The snubber diffusion assembly, Figure 1- 4, is satisfactory for most applications. This element is also available with a dust seal for use with an abrasive shield.

36220006

Figure 1-4. Flame Arrestor Snubber Diffusion

Assembly

Rosemount Analytical Inc. A Division of Emerson Process Management |