Product Description

2.2Operational Overview - Water/Glycol Cooled Model

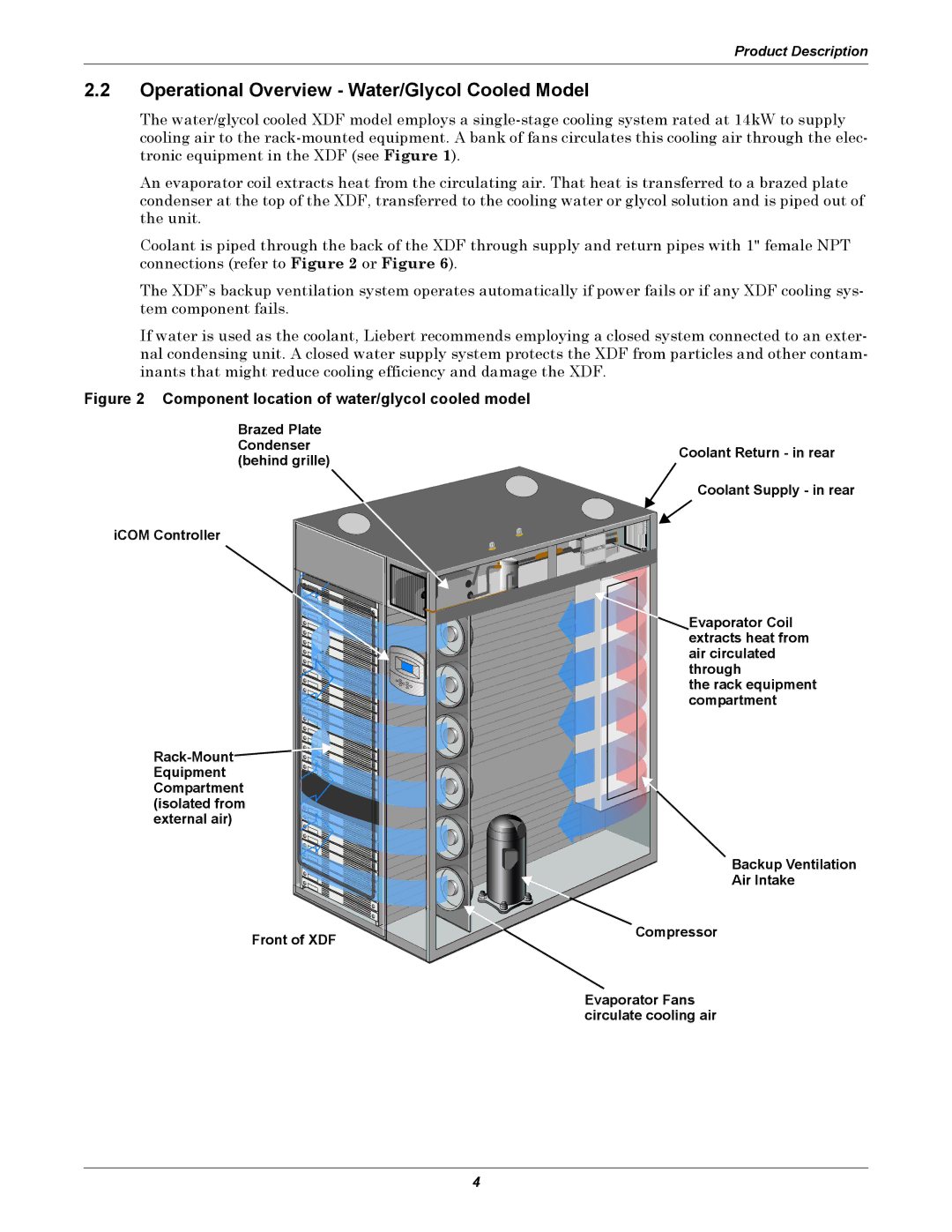

The water/glycol cooled XDF model employs a

An evaporator coil extracts heat from the circulating air. That heat is transferred to a brazed plate condenser at the top of the XDF, transferred to the cooling water or glycol solution and is piped out of the unit.

Coolant is piped through the back of the XDF through supply and return pipes with 1" female NPT connections (refer to Figure 2 or Figure 6).

The XDF’s backup ventilation system operates automatically if power fails or if any XDF cooling sys- tem component fails.

If water is used as the coolant, Liebert recommends employing a closed system connected to an exter- nal condensing unit. A closed water supply system protects the XDF from particles and other contam- inants that might reduce cooling efficiency and damage the XDF.

Figure 2 Component location of water/glycol cooled model

Brazed Plate Condenser (behind grille)

iCOM Controller

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Compartment

Compartment ![]()

![]()

![]()

![]()

![]() (isolated from

(isolated from ![]()

![]()

![]()

![]()

![]() external air)

external air) ![]()

![]()

Front of XDF

Coolant Return - in rear

Coolant Supply - in rear

![]()

![]()

Evaporator Coil

Evaporator Coil

extracts heat from air circulated through

the rack equipment compartment

Backup Ventilation

Air Intake

Compressor

Evaporator Fans circulate cooling air

4