Piping

5.0PIPING CONSIDERATIONS—WATER/GLYCOL MODELS ONLY

The XDF’s supply and return fittings are on the upper portion of the rear of the unit (see Figure 6). The

5.1General

Equipment damage and personal injury can result from improper piping installation, leak checking, fluid chemistry and fluid maintenance.

• Follow local piping codes, safety codes and Liebert unit installation and maintenance instruc- tions.

• Qualified personnel must install and inspect system piping.

• Contact a local water consultant regarding water quality, corrosion protection and freeze protec- tion requirements.

! CAUTION

Risk of dirt and debris contamination. May cause condenser clogging.

Do not install the XDF on an

! CAUTION

Risk of piping stress. Can cause leaks and equipment damage.

To help prevent piping failures, supply and return lines must be supported so that their weight does not bear on the XDF’s piping, on the drycooler or on the pumps.

5.2Closed Loop Water System

Where water will be used as a coolant medium, Liebert recommends use of a

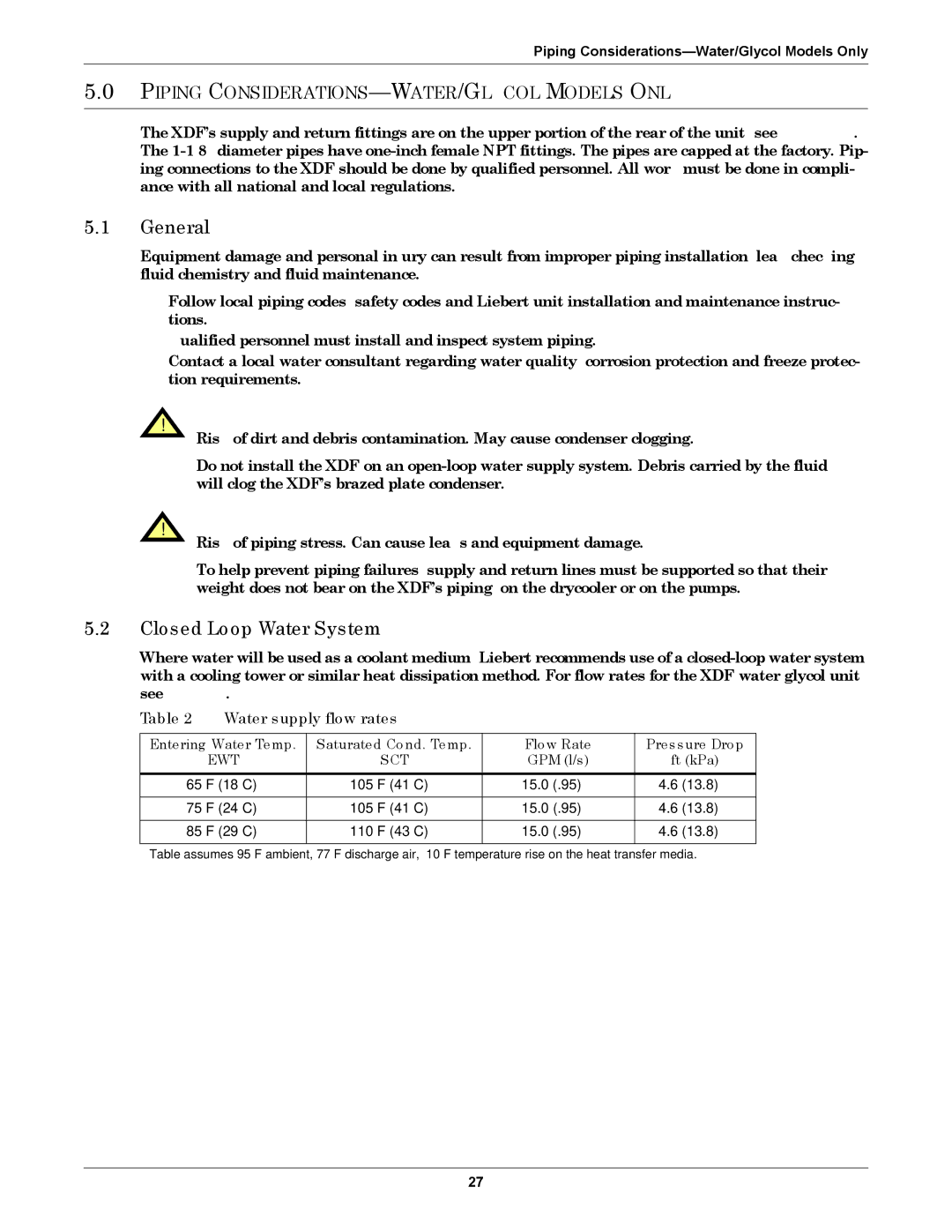

Table 2 | Water supply flow rates |

|

| |

|

|

|

| |

Entering Water Temp. | Saturated Cond. Temp. | Flow Rate | Pressure Drop | |

| EWT | SCT | GPM (l/s) | ft (kPa) |

65°F (18°C) | 105°F (41°C) | 15.0 (.95) | 4.6 (13.8) | |

|

|

|

| |

75°F (24°C) | 105°F (41°C) | 15.0 (.95) | 4.6 (13.8) | |

|

|

|

| |

85°F (29°C) | 110°F (43°C) | 15.0 (.95) | 4.6 (13.8) | |

|

|

|

|

|

Table assumes 95°F ambient, 77°F discharge air, 10°F temperature rise on the heat transfer media.

27