Piping

5.3Drycooler Loop System

5.3.1Glycol Solutions

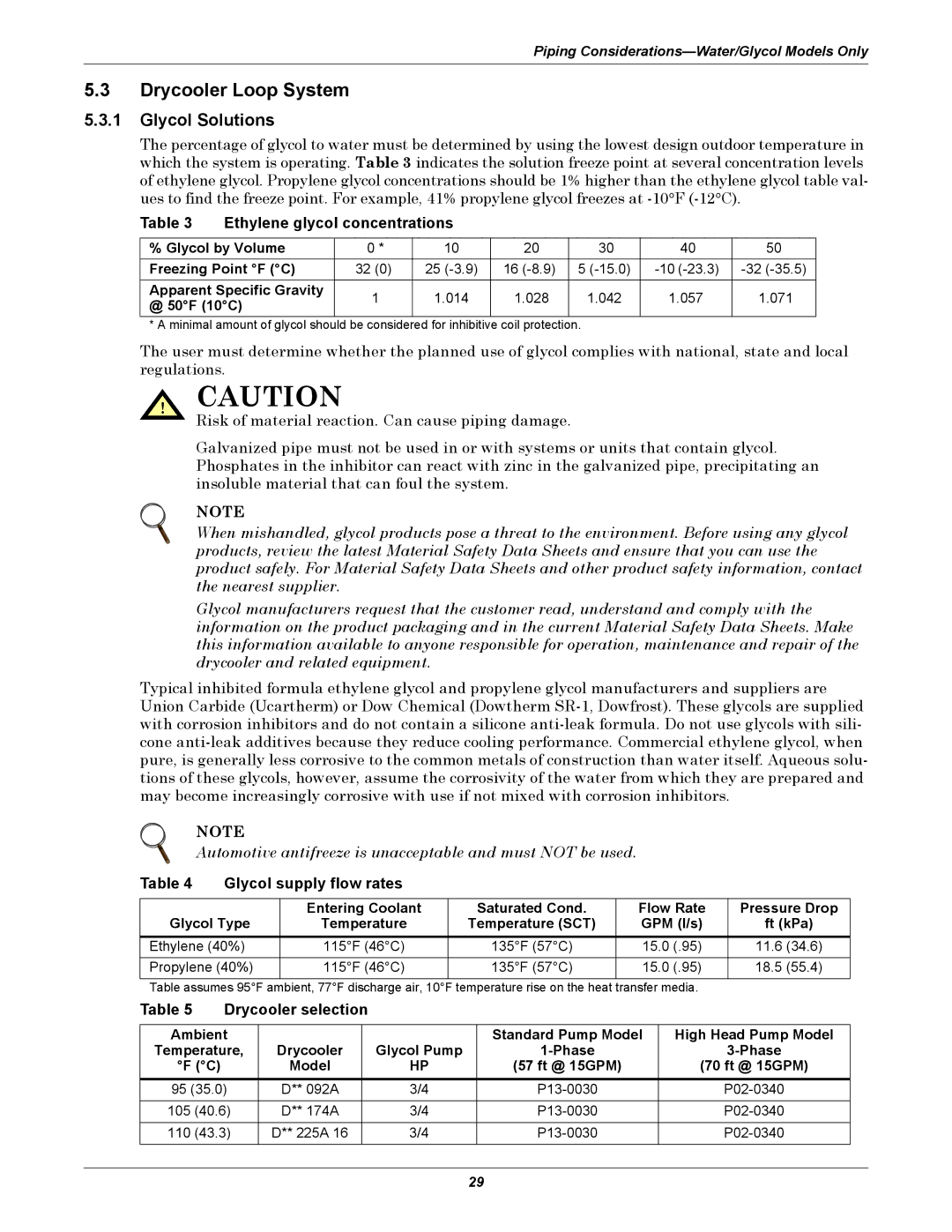

The percentage of glycol to water must be determined by using the lowest design outdoor temperature in which the system is operating. Table 3 indicates the solution freeze point at several concentration levels of ethylene glycol. Propylene glycol concentrations should be 1% higher than the ethylene glycol table val- ues to find the freeze point. For example, 41% propylene glycol freezes at

Table 3 Ethylene glycol concentrations

% Glycol by Volume | 0 * | 10 | 20 | 30 | 40 | 50 | |

Freezing Point °F (°C) | 32 (0) | 25 | 16 | 5 | |||

Apparent Specific Gravity | 1 | 1.014 | 1.028 | 1.042 | 1.057 | 1.071 | |

@ 50°F (10°C) | |||||||

|

|

|

|

|

|

* A minimal amount of glycol should be considered for inhibitive coil protection.

The user must determine whether the planned use of glycol complies with national, state and local regulations.

! CAUTION

Risk of material reaction. Can cause piping damage.

Galvanized pipe must not be used in or with systems or units that contain glycol. Phosphates in the inhibitor can react with zinc in the galvanized pipe, precipitating an insoluble material that can foul the system.

NOTE

When mishandled, glycol products pose a threat to the environment. Before using any glycol products, review the latest Material Safety Data Sheets and ensure that you can use the product safely. For Material Safety Data Sheets and other product safety information, contact the nearest supplier.

Glycol manufacturers request that the customer read, understand and comply with the information on the product packaging and in the current Material Safety Data Sheets. Make this information available to anyone responsible for operation, maintenance and repair of the drycooler and related equipment.

Typical inhibited formula ethylene glycol and propylene glycol manufacturers and suppliers are Union Carbide (Ucartherm) or Dow Chemical (Dowtherm

NOTE

Automotive antifreeze is unacceptable and must NOT be used.

Table 4 | Glycol supply flow rates |

|

|

| |

|

|

|

|

|

|

|

| Entering Coolant | Saturated Cond. | Flow Rate | Pressure Drop |

Glycol Type | Temperature | Temperature (SCT) | GPM (l/s) | ft (kPa) | |

Ethylene (40%) | 115°F (46°C) | 135°F (57°C) | 15.0 (.95) | 11.6 (34.6) | |

Propylene (40%) | 115°F (46°C) | 135°F (57°C) | 15.0 (.95) | 18.5 (55.4) | |

|

|

|

|

|

|

Table assumes 95°F ambient, 77°F discharge air, 10°F temperature rise on the heat transfer media.

Table 5 | Drycooler selection |

|

|

| ||

|

|

|

|

|

| |

Ambient |

|

|

| Standard Pump Model | High Head Pump Model | |

Temperature, | Drycooler |

| Glycol Pump | |||

°F (°C) |

| Model |

| HP | (57 ft @ 15GPM) | (70 ft @ 15GPM) |

95 (35.0) | D** 092A |

| 3/4 | |||

105 (40.6) | D** 174A |

| 3/4 | |||

|

|

|

|

|

| |

110 (43.3) | D** 225A 16 |

| 3/4 | |||

|

|

|

|

|

|

|

29