Maintenance

11.0MAINTENANCE

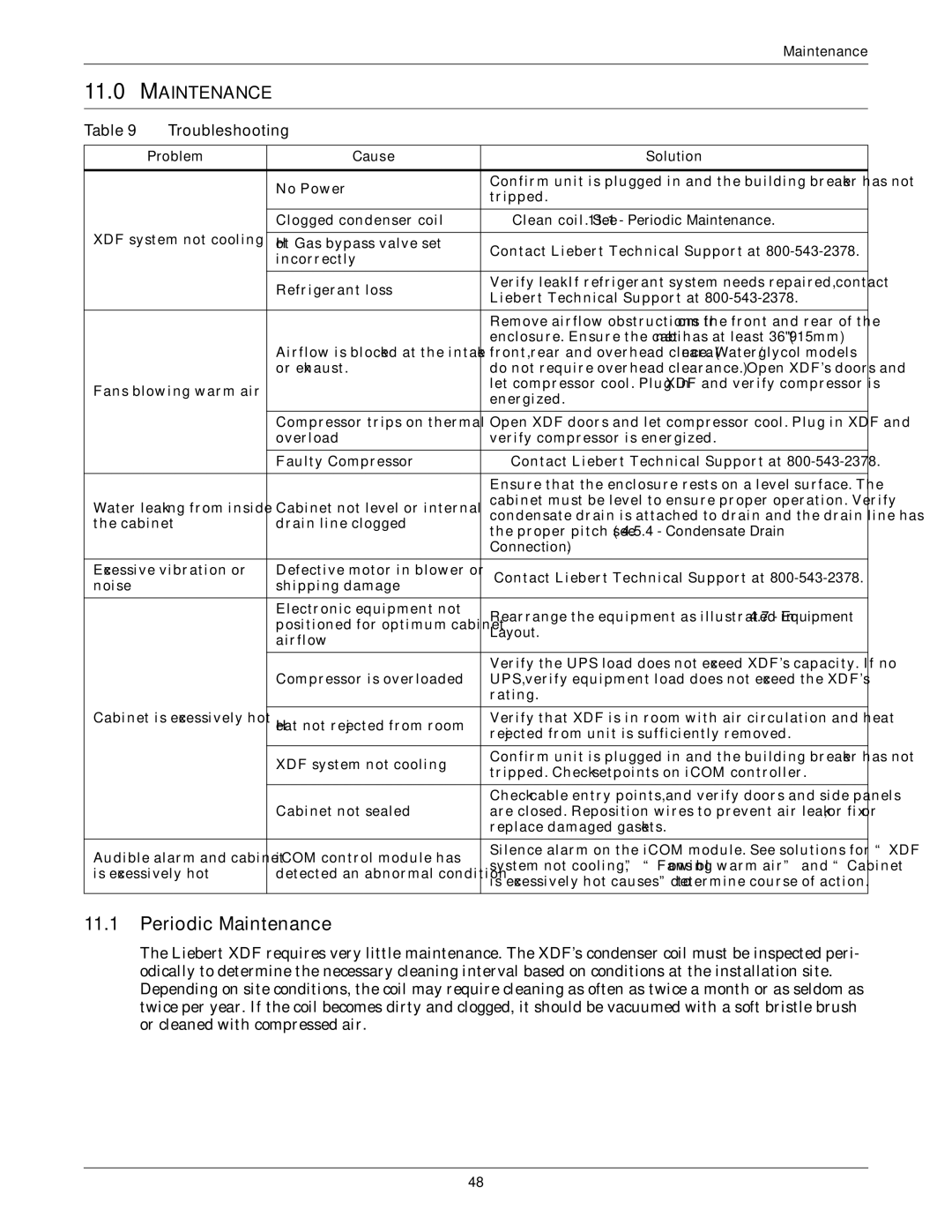

Table 9 | Troubleshooting |

| ||

|

|

|

| |

| Problem | Cause | Solution | |

|

|

|

| |

|

| No Power | Confirm unit is plugged in and the building breaker has not | |

|

| tripped. | ||

|

|

| ||

|

| Clogged condenser coil | Clean coil. See 11.1 - Periodic Maintenance. | |

XDF system not cooling |

|

| ||

Hot Gas bypass valve set | Contact Liebert Technical Support at | |||

|

| incorrectly | ||

|

|

| ||

|

| Refrigerant loss | Verify leak. If refrigerant system needs repaired, contact | |

|

| Liebert Technical Support at | ||

|

|

| ||

|

|

| Remove airflow obstructions from the front and rear of the | |

|

|

| enclosure. Ensure the cabinet has at least 36" (915mm) | |

|

| Airflow is blocked at the intake | front, rear and overhead clearance. (Water/glycol models | |

|

| or exhaust. | do not require overhead clearance.) Open XDF’s doors and | |

Fans blowing warm air |

| let compressor cool. Plug in XDF and verify compressor is | ||

| energized. | |||

|

|

| ||

|

| Compressor trips on thermal | Open XDF doors and let compressor cool. Plug in XDF and | |

|

| overload | verify compressor is energized. | |

|

| Faulty Compressor | Contact Liebert Technical Support at | |

|

|

|

| |

|

|

| Ensure that the enclosure rests on a level surface. The | |

Water leaking from inside | Cabinet not level or internal | cabinet must be level to ensure proper operation. Verify | ||

condensate drain is attached to drain and the drain line has | ||||

the cabinet | drain line clogged | |||

the proper pitch (see 4.5.4 - Condensate Drain | ||||

|

|

| ||

|

|

| Connection). | |

|

|

| ||

Excessive vibration or | Defective motor in blower or | Contact Liebert Technical Support at | ||

noise |

| shipping damage | ||

|

| |||

|

| Electronic equipment not | Rearrange the equipment as illustrated in 4.7 - Equipment | |

|

| positioned for optimum cabinet | ||

|

| Layout. | ||

|

| airflow | ||

|

|

| ||

|

|

|

| |

|

|

| Verify the UPS load does not exceed XDF’s capacity. If no | |

|

| Compressor is overloaded | UPS, verify equipment load does not exceed the XDF’s | |

|

|

| rating. | |

Cabinet is excessively hot | Heat not rejected from room | Verify that XDF is in room with air circulation and heat | ||

|

| rejected from unit is sufficiently removed. | ||

|

|

| ||

|

| XDF system not cooling | Confirm unit is plugged in and the building breaker has not | |

|

| tripped. Check setpoints on iCOM controller. | ||

|

|

| ||

|

|

| Check cable entry points, and verify doors and side panels | |

|

| Cabinet not sealed | are closed. Reposition wires to prevent air leak, or fix or | |

|

|

| replace damaged gaskets. | |

Audible alarm and cabinet | iCOM control module has | Silence alarm on the iCOM module. See solutions for “XDF | ||

system not cooling,” “Fans blowing warm air” and “Cabinet | ||||

is excessively hot | detected an abnormal condition | |||

is excessively hot causes” to determine course of action. | ||||

|

|

| ||

|

|

|

| |

11.1Periodic Maintenance

The Liebert XDF requires very little maintenance. The XDF’s condenser coil must be inspected peri- odically to determine the necessary cleaning interval based on conditions at the installation site. Depending on site conditions, the coil may require cleaning as often as twice a month or as seldom as twice per year. If the coil becomes dirty and clogged, it should be vacuumed with a soft bristle brush or cleaned with compressed air.

48