XDT User’s Manual

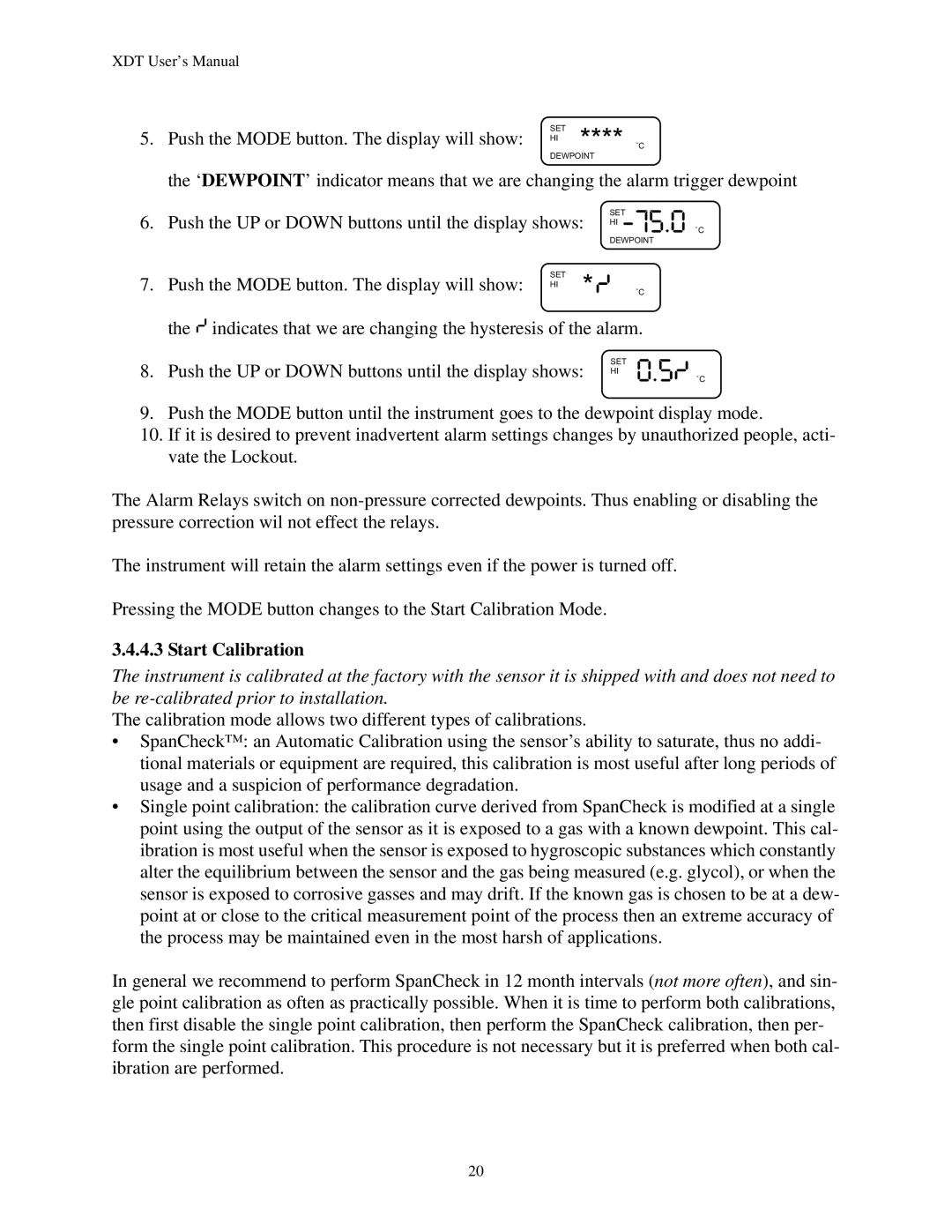

5. Push the MODE button. The display will show:

SET

HI **** ˚C

DEWPOINT

the ‘DEWPOINT’ indicator means that we are changing the alarm trigger dewpoint

6. | Push the UP or DOWN buttons until the display shows: | SET | |

HI | |||

|

|

| ˚C |

|

|

| DEWPOINT |

| SET | * |

|

7. | Push the MODE button. The display will show: HI | ˚C | |

the Z indicates that we are changing the hysteresis of the alarm.

8. Push the UP or DOWN buttons until the display shows: | SET |

HI | |

| ˚C |

9.Push the MODE button until the instrument goes to the dewpoint display mode.

10.If it is desired to prevent inadvertent alarm settings changes by unauthorized people, acti- vate the Lockout.

The Alarm Relays switch on

The instrument will retain the alarm settings even if the power is turned off.

Pressing the MODE button changes to the Start Calibration Mode.

3.4.4.3 Start Calibration

The instrument is calibrated at the factory with the sensor it is shipped with and does not need to be

The calibration mode allows two different types of calibrations.

•SpanCheck™: an Automatic Calibration using the sensor’s ability to saturate, thus no addi- tional materials or equipment are required, this calibration is most useful after long periods of usage and a suspicion of performance degradation.

•Single point calibration: the calibration curve derived from SpanCheck is modified at a single point using the output of the sensor as it is exposed to a gas with a known dewpoint. This cal- ibration is most useful when the sensor is exposed to hygroscopic substances which constantly alter the equilibrium between the sensor and the gas being measured (e.g. glycol), or when the sensor is exposed to corrosive gasses and may drift. If the known gas is chosen to be at a dew- point at or close to the critical measurement point of the process then an extreme accuracy of the process may be maintained even in the most harsh of applications.

In general we recommend to perform SpanCheck in 12 month intervals (not more often), and sin- gle point calibration as often as practically possible. When it is time to perform both calibrations, then first disable the single point calibration, then perform the SpanCheck calibration, then per- form the single point calibration. This procedure is not necessary but it is preferred when both cal- ibration are performed.

20