XDT User’s Manual Appendices

Appendix H: Sample Gas Filter Considerations

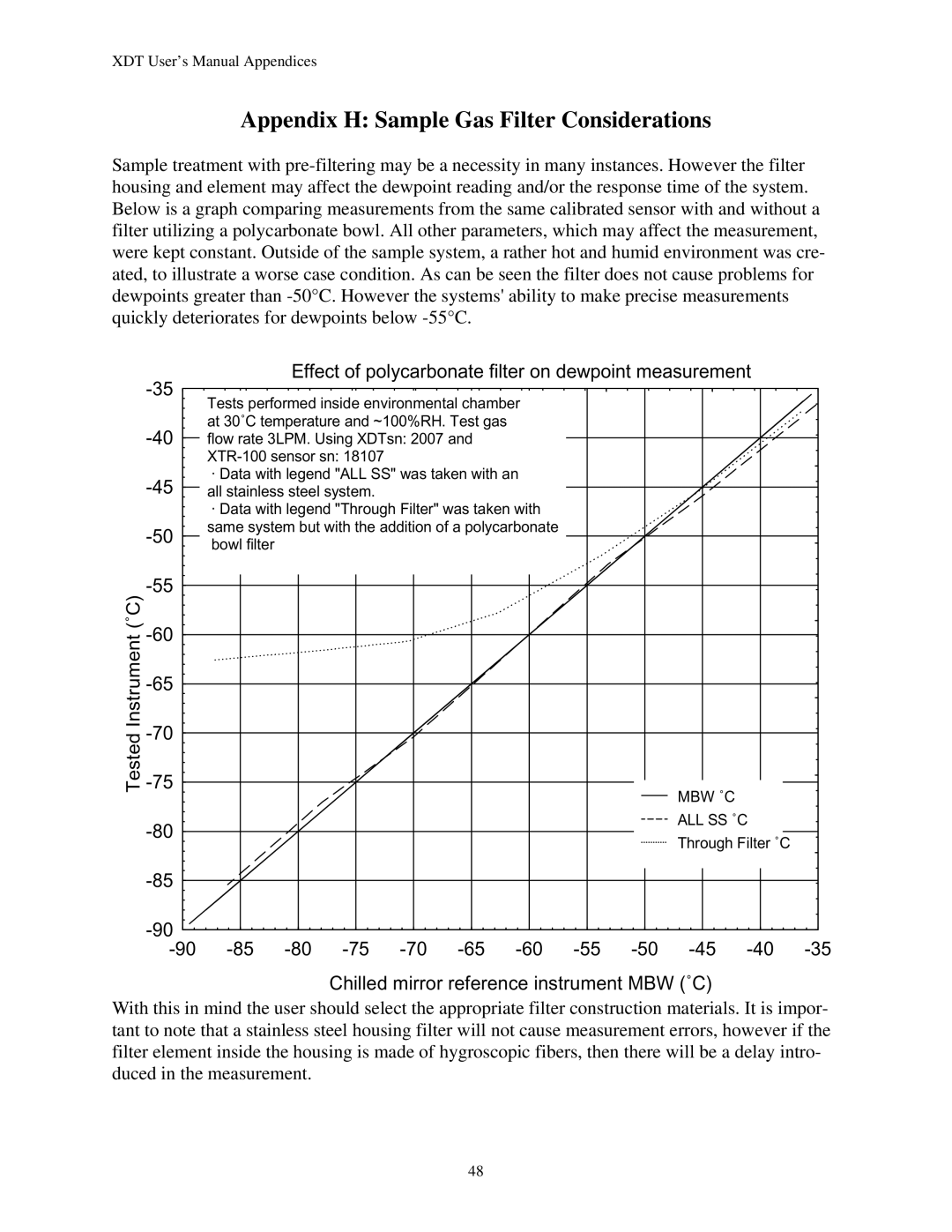

Sample treatment with

Tested Instrument (˚C)

Effect of polycarbonate filter on dewpoint measurement | ||

Tests performed inside environmental chamber | ||

| ||

at 30˚C temperature and ~100%RH. Test gas | ||

flow rate 3LPM. Using XDTsn: 2007 and | ||

|

·Data with legend "ALL SS" was taken with an

all stainless steel system. | ||

| · Data with legend "Through Filter" was taken with | |

same system but with the addition of a polycarbonate | ||

bowl filter | ||

| ||

| ||

| ||

| ||

| ||

MBW ˚C | ||

| ||

ALL SS ˚C | ||

Through Filter ˚C | ||

| ||

| ||

| ||

Chilled mirror reference instrument MBW (˚C)

With this in mind the user should select the appropriate filter construction materials. It is impor- tant to note that a stainless steel housing filter will not cause measurement errors, however if the filter element inside the housing is made of hygroscopic fibers, then there will be a delay intro- duced in the measurement.

48