MANUALUSER’S 24-wire dot matrix printers

User’s Manual

User’s Manual

Manufacturers Declaration of Conformity

Trademark Acknowledgment

User’s Manual

User’s Manual

Contents

10-1

Changing Head Gap Adjustment Options

12-1

11-1

IN-1

Image and graphics reproduction

Introduction

Package

Contents

Functions

Parts

Inside

Or continuous forms width

Lists the printer parts and functions

Recommended

Setting Up the Printer

Removing Stopper Cushion

Check that the jam removal lever is locked

Installing the Paper Guide

Insert the platen knob and align it with the gear teeth

Installing the Platen Knob

Plug the power cord into an outlet

Connecting the Power Cord

Connecting the Interface Cable

User’s Manual

Choosing a Cassette

Installing the Ribbon Cassette

Preparing the Ribbon Cassette

Installing the Ribbon Cassette

Close the top cover of the printer

Removing the Ribbon Cassette

Lift the reverse guide and remove the old ribbon

Replacing the Subcassette

Paper tape

Knob Lock tabs B

Turn on the printer power switch

Loading Paper

Loading Continuous Forms Front

Loading Continuous Forms Front

Tractor pins Paper holders Tractors Continuous forms

Close the front cover of the printer

Lower the cut-sheet tray

Indicator

Loading

Forms Rear Cutting

Forms

Turn on printer power

Raise the paper guide. See Installing the Paper Guide on

Loading Cut Sheets

Align the cut-sheet guide with the reference point

Open the front tray

Cut-sheet guide Cut sheet

Printing on Cut Sheets

Cut sheet Continuous forms

Returning to Continuous Forms

Online

Using

Operating the Printer

Control Panel

Locked

Friction

Front Tractor

Rear Tractor

Load

LF/FF

Font

Lock

Online + Tear OFF

Menu

Tear OFF

Paper Path

Friction *2

Power

Alarm

Online *2

Next Display

Online *1

Turning Printer Power On Off Test Printing

Test Printing

Test printing sample

Demonstration Pattern Printing

Demonstration pattern

Sensor Detection

User’s Manual

Clearing Paper Jams

Continuous Forms Front

Top cover Print head Paper thickness lever

Cut Sheets

Cut Sheets

User’s Manual

Shows the size range for continuous forms

Paper Specifications

Continuous Forms

Parts do not separate or

Become misaligned easily

Misaligned

Types of binding

Single-sided zigzag spot gluing Combination of the other two

30 mm

Printing

Area Size in mm Remarks

Type Number Ream weight in g/cm Front

Paste here FrontSide

Labels

Ambient temperature 40C

Or more

25.4

Formats

Recommended label formats

Label arrangement

Preprinting

Precautions

Leave an interval of 8 mm 0.3 in or greater

Unit mm

Miscellaneous

Overview

Setup Mode

Chapter Organization Activating Setup Mode

Initial setup mode printout

Mode

Using Setup

Using Setup Mode

Setup mode summary

Exit setup mode, saving the new font and spacing

Printing a List of Options

Default settings at shipment

MENU1 Emulate

Setting Required Options

Changing MENU1 MENU2 Options

DPL24C+

XL24E

ESC/P2

Draft

Quality

Letter

Report

CHAR-H

CHAR-W

Normal

Times

Condnsd

Attrib

None

Italics

TOP-MRG

Swedish

Languge

USA

German

ISO-LTN

ELOT928

PG-DHN

LATIN-P

Graphic

CHR-SET

SET

Italic

CR & LF

Enable

Disable

CR-CODE CR only

OVR-PRT

Rghtend Wrap

End-of-line wrap. Causes a carriage return plus a line

Feed

Change other MENU1 or MENU2 options as required

Select MENU1 or MENU2

ADJUST, or Config

Default does not reset options handled by Hardware

Hardware

Changing

2KBYTE2

WORD-LG

BIT

Buffer

REV-CHL

SPACE1

XON/XOF

DTR

Printer detects CD

Printer ignores CD

Changing Print Adjustment Options

Cutfine

CNT-ORG

Cntfine

CUT-ORG

Fcntadj

Rcntadj

CUT-ADJ

CNT-ORG

Tearpos Visible

Changing Configuration Options

Tearoff Manual

Auto

Loadtim

TEAR-EN SEC

Cutload Auto

Button

Tractor

Setup

ALL

CONT-PE

Tearoff Manual Auto

PLY POS.A POS.B POS.C POS.D Manual

Changing Head Gap Adjustment Options

Amount

PLY

Select SAVE&END

Resetting Default Values

Using Diagnostic Functions

Test printing SELF-TST

Hex dump printing HEX-DUMP

Sample hex dump

Checking vertical print alignment V-ALMNT

Bars offset to the left

Correct vertical printing alignment

You can also exit setup mode to exit V-ALMNT

Listed for IBM Proprinter XL24E and Epson ESC/P2 emulations

Setup Mode

Flowchart in -6 shows the setup mode for the Fujitsu

Reference

Hardwre Adjust Config GAP-ADJ

LF code

AGM

Performing Online Setup

Print head

Ribbon cassette

Correct continuous forms loading

User’s Manual

To troubleshoot printer problems, follow the flowchart

Troubleshooting

Troubleshooting

Inspection Maintenance

Daily Inspection and Maintenance

11-2

Specifications

Vertical ⋅

Configuration body Horizontal Face Draft Quality

Printer Specifications Printer specifications

Parallel two pins

Dimensions

D86B-1138-C359 for DL6600 Pro

Consumables and Options

Aptc

D86B-1138-C353 for DL6600 Pro

User’s Manual

Command Sets

Fujitsu DPL24C

Select underline type

Condensed characters off

DC2

ESC T

ESC P

Space Backspace Carriage return Elite 12 cpi

ESC M

Pica 10 cpi

255 ESC J n

Line feed Reverse line feed

ESC LF

Form feed

ESC O

Horizontal tab execution

255 ESC VT n

Set right margin 0 ≤ n ≤ ESC Q n

ESC =

Can

DC1

DC3

Resident font

ESC % m n

Select font m with source and style set by n

Bits 0 and 1 Font device selection

255 0 ≤ n2 ≤

Select character spacingn/360 inch, font attributes

Fixed 10 cpi 12 pt

ESC NUL m n

Bits 4 and 5 Specifies the quality of characters to be reg

Istered

Cut-Sheet Feeder Control

EAN

Codabar nw-7 EAN

Ignore the paper-out sensor

Enable paper-out sensor

Sound bell

BEL

LETTER, REPORT, Draft

Cour 10, Prstg 12, Comprsd

BOLDFCE, Pica 10, Corresp

Downld 0, Downld ESC %

ESC G ESC H

NONE, ITALICS, Condnsd

SHADOW, Bold

ESC E ESC F

LF-ONLY, LF & CR

DC1/DC3 ENABLE, Disable

NO-SLSH, Slash

CR-ONLY, CR & LF

DC4

Unchanged Normal Double Single M4 controls character width

Unchanged Normal Double

≤ t1 ≤ 255, 0 ≤ t2 ≤ 255, t3 = 0, t4 = 180 or

Space Backspace Carriage return Elite characters on

Set line spacing to 7/72 inch

Set line spacing to n/216 inch 0 ≤ n ≤ ESC 3 n

ESC B NUL

ESC D NUL

ESC Q #

ESC EM

ESC EM E

ESC EM R

Underline on or off ESC n On n = 1, off n =

ESC n 1 n

Select line

Line feed Form feed

Space Backspace Carriage return Set elite

Set pica

ESC c n1 n2

ESC D

127 ESC C n Set page length to n inches 1 ≤ n ≤ ESC C NUL n

255 0 ≤

ESC t n

Delete character

DEL

ESC % n

Print raster image graphics

ESC X m n 1 n

Point

ESC * m n 1 n 2 data

ESC @

Enter online setup mode ESC e Online data

User’s Manual

Parallel Interface

Interface Information

ACK

Dstb

Slct

Inprm

Data transfer, it is used as data bit

This signal is set low when the printer is

This signal is used to indicate that data is

Ready to send data to the host. During

Figure C-1 Data transmission timing

Data Transmission Timing

Figure C-2 Data transmission timing

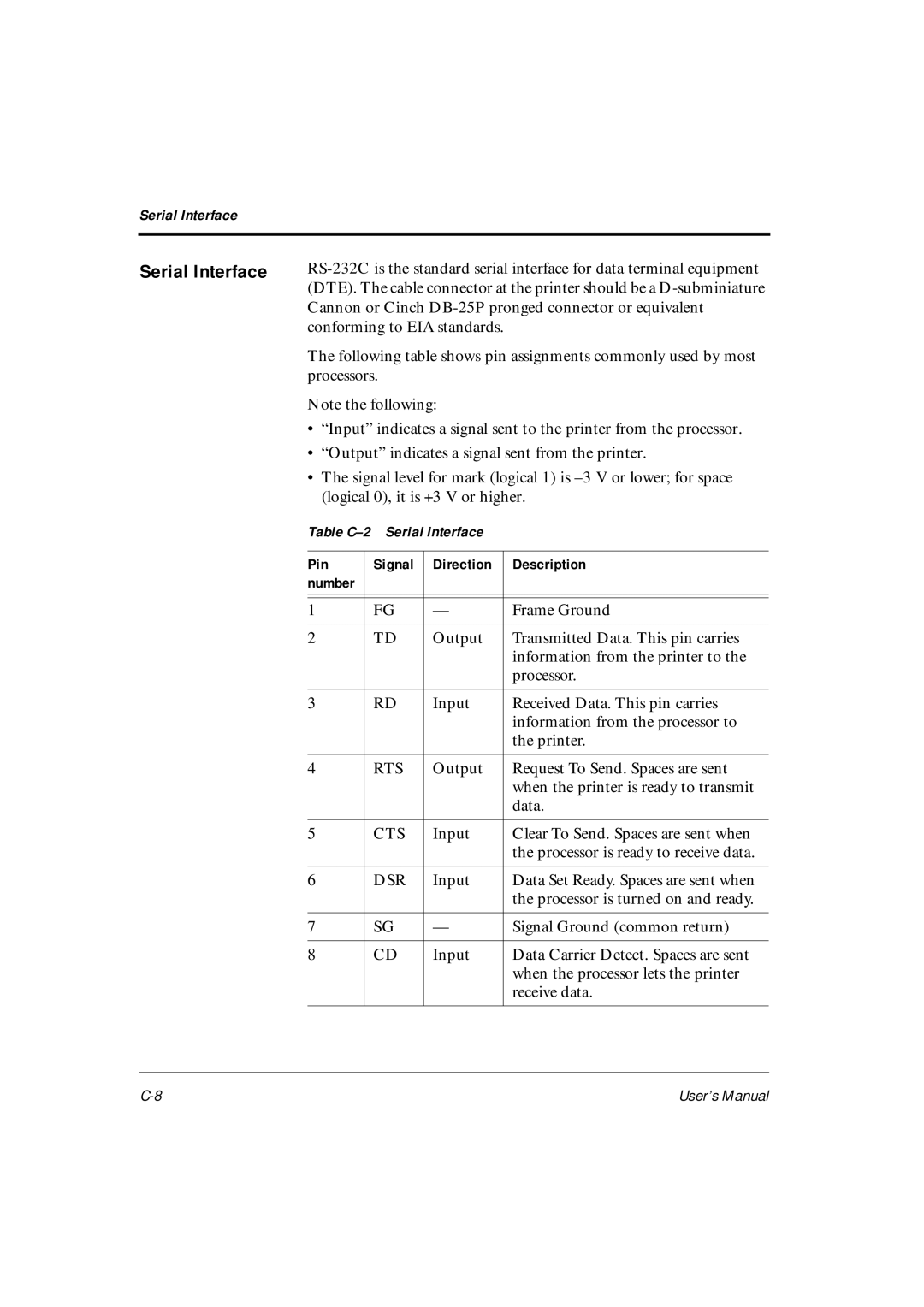

Serial Interface

RTS

CTS

ETX/ACK selectable

When the printer is turned on

Serial Options

Ready

TD RD

Cable Wiring

Figure C-1 Cable wiring DSR-enabled control

Serial Protocols

ON/XOFF

ETX/ACK

Basic character sets for DPL24C Plus and IBM XL24E emulation

Character Sets

User’s Manual

User’s Manual

User’s Manual

User’s Manual

User’s Manual

User’s Manual

LITHUA1 Lithuanian LITHUA2 Lithuanian

MIK

User’s Manual

User’s Manual

User’s Manual

User’s Manual

User’s Manual

Character Sets

Ecma ECMA94

USA*2

PG-MAC ELOT927

LATN2-T

LITHUA2 MIK

Macedon ABG ABY

User’s Manual

Using the LCD/LED Type Control Panel

Control panel components

LCD screen

Indicator lights

Unload

Buttons

Points to remember about basic menus

Menus and functions

Executes form feed

Changes the font, print quality, and pitch

Executes line feed

Backward. To invert the arrow, press the ↓↑ but- ton

Executing a form feed or line feed

Executing a micro line feed

To execute a form feed or line feed

To tear off continuous forms

Resetting the printer

To reset the printer

Tearing off continuous forms

Changing print font, quality, and pitch temporarily

Letter Report Draft

Selecting MENU1 or MENU2

Entering setup mode

Enabling or disabling lock mode

Exiting setup mode

Selecting options

Using the Setup Menus

Selections are not in effect until they are saved

Starting functions

Example of operations

Save Exit from Setup SELF-TEST Alignment

Saving changed options

Selecting options in MENU1 and MENU2

Using the Save function

Exit from Setup

Press F1 until SELF-TEST appears under Func

Printing the self-test

Correcting vertical character displacement

Power-on Special Functions

Exit

Messages

Stop

USE Save

Appears for 2 seconds immediately

Where line 001 is the top-of-form

Where xxxx is -128 to +127

Internal test Printer is performing its

Exit Stop GO

Speed Incr Decr

MICRO↑ Exit Save

Operational error messages

Messages indicating user-correctable problems

LCD model

Cover open Cover is open Shut the cover Error

Table E-5 Warning errors list

Table E-5 Warning errors list

Buffer overflow

Or check the interface cable

Table E-6 lists nonfatal error messages alphabetically

Space for download data, or check the format

Download data

Compress

Messages indicating fatal errors

Cour

Prestg

Fatal

Index

Index

Platen Platen knob

IN-4

IN-5

IN-6

Fujitsu Offices

C147-E041-05EN