5HDU&RQWURO | /DPLQDWRU3XOO5ROO3UHVVXUH | Operation |

|

|

The switch on the back of the drive cabinet starts and stops the main rolls when pressed while guards are in place.

Rear

RUN/STOP

Switch

6HWXSFigure 3-6: ear RUN/STOP Switch

Setup of the

/DPLQDWRUTo adjust the nip,0DLQplease5ROOsee3UHVVXUHMaintenance.

Use only the minimum amount of roll pressure needed to accomplish the task. While higher pressure can make the adhesive bond faster, excess pressure can damage the rolls. Wrinkles and bubbles have causes that gener- ally cannot be cured by applying more pressure.

![]() CAUTION

CAUTION

Excess pressure can damage the laminating rolls. Minimum laminator roll pressure is consistent with good results.

A typical roll pressure for soft substrates such as Foam- core is between 30 to 40%.

The range of typical values for hard substrates is 30 to 50%.

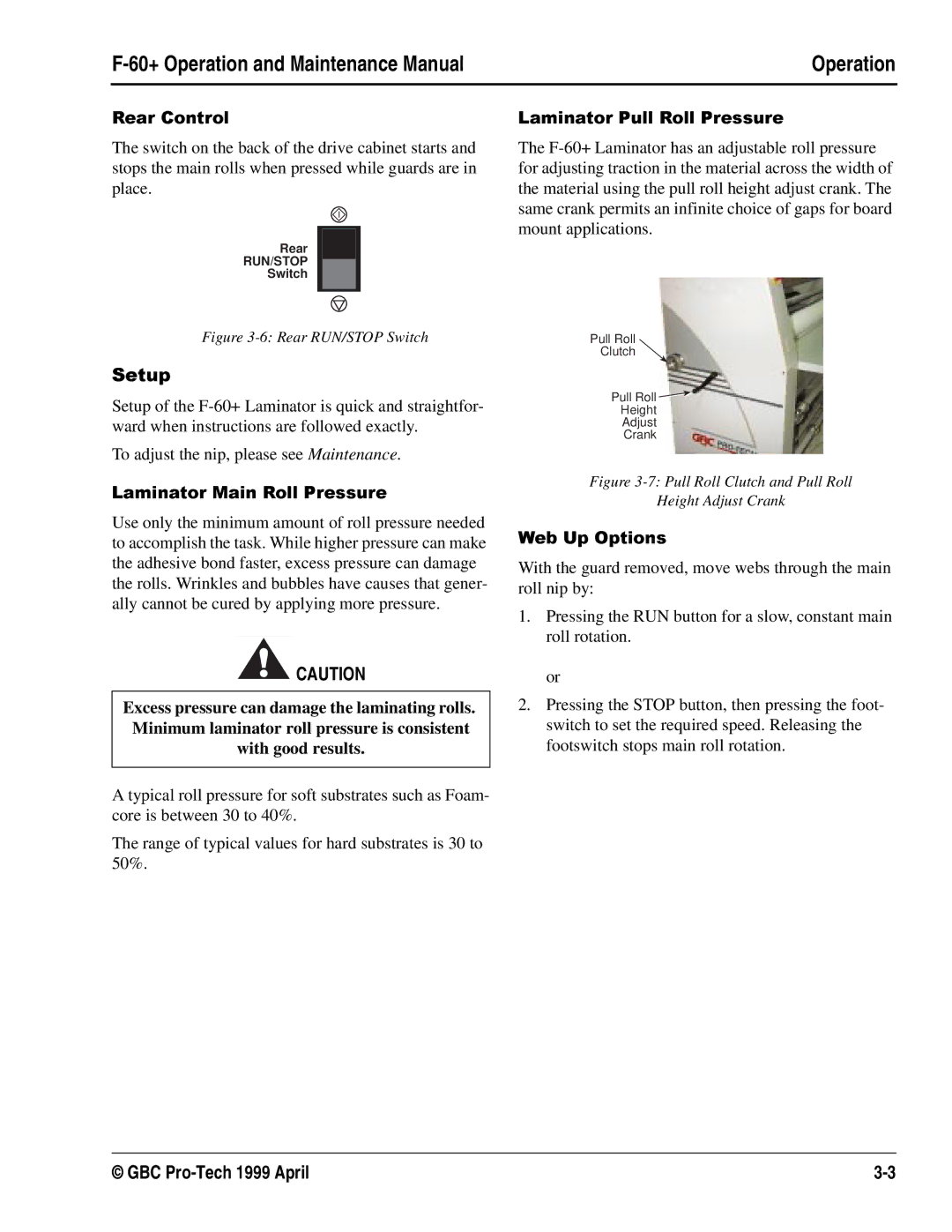

The

Pull Roll

Clutch

Pull Roll ![]()

Height

Adjust

Crank

Figure 3-7: Pull Roll Clutch and Pull Roll

:HE8S | Height Adjust Crank |

With the guard removed, move webs through the main roll nip by:

1.Pressing the RUN button for a slow, constant main roll rotation.

or

2.Pressing the STOP button, then pressing the foot- switch to set the required speed. Releasing the footswitch stops main roll rotation.

© GBC |