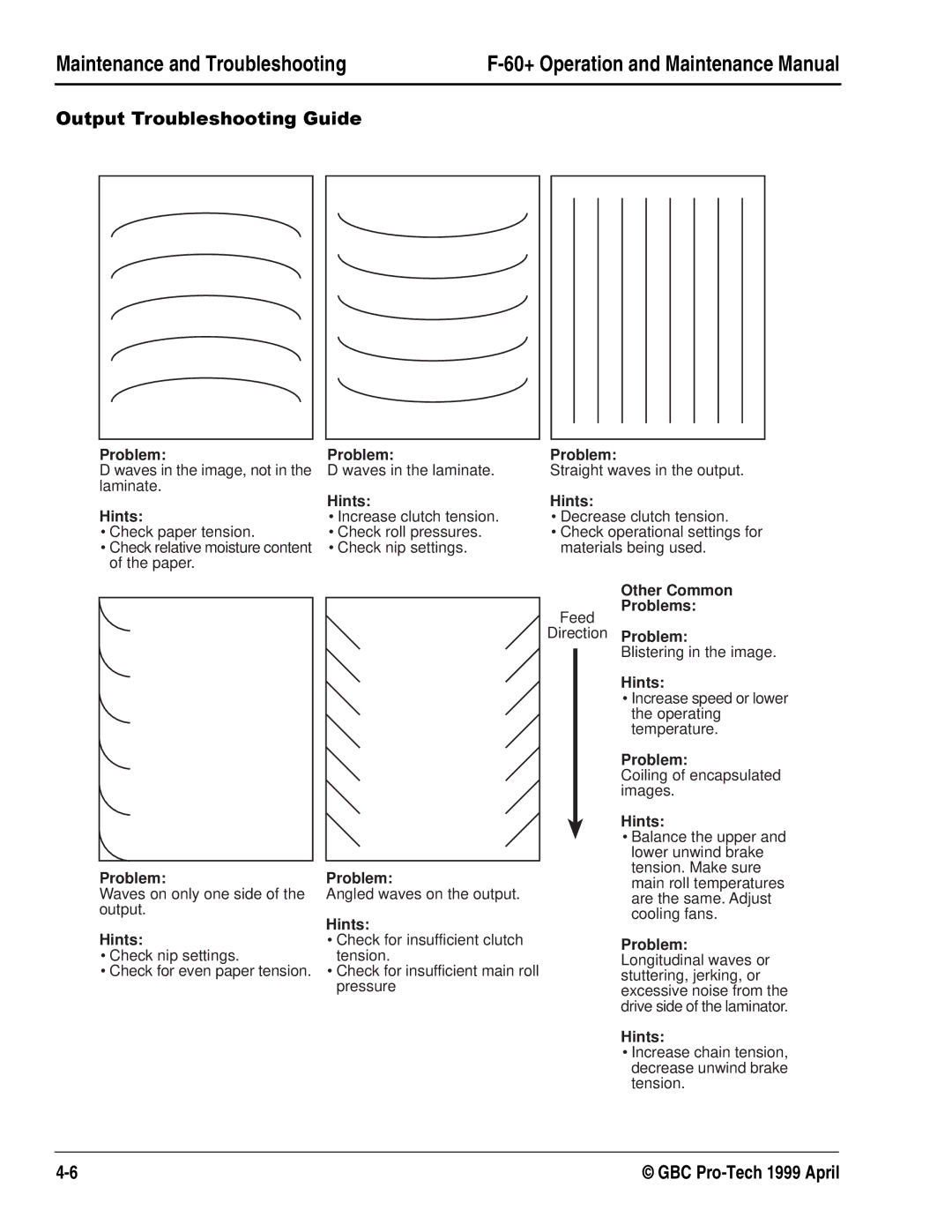

2XWSXW7URXEOHVKRRWLQJ*XLGH |

|

Maintenance and Troubleshooting |

Problem:

D waves in the image, not in the laminate.

Hints:

•Check paper tension.

•Check relative moisture content of the paper.

Problem:

Waves on only one side of the output.

Hints:

•Check nip settings.

•Check for even paper tension.

Problem:

D waves in the laminate.

Hints:

•Increase clutch tension.

•Check roll pressures.

•Check nip settings.

Problem:

Angled waves on the output.

Hints:

•Check for insufficient clutch tension.

•Check for insufficient main roll pressure

Problem:

Straight waves in the output.

Hints:

•Decrease clutch tension.

•Check operational settings for materials being used.

Other Common

Problems:

Feed

Direction Problem:

Blistering in the image.

Hints:

•Increase speed or lower the operating temperature.

Problem:

Coiling of encapsulated images.

Hints:

•Balance the upper and lower unwind brake tension. Make sure main roll temperatures are the same. Adjust cooling fans.

Problem: Longitudinal waves or stuttering, jerking, or excessive noise from the drive side of the laminator.

Hints:

•Increase chain tension, decrease unwind brake tension.

© GBC |