Operation | 3URFHVV &RQWURO&KDUWV |

|

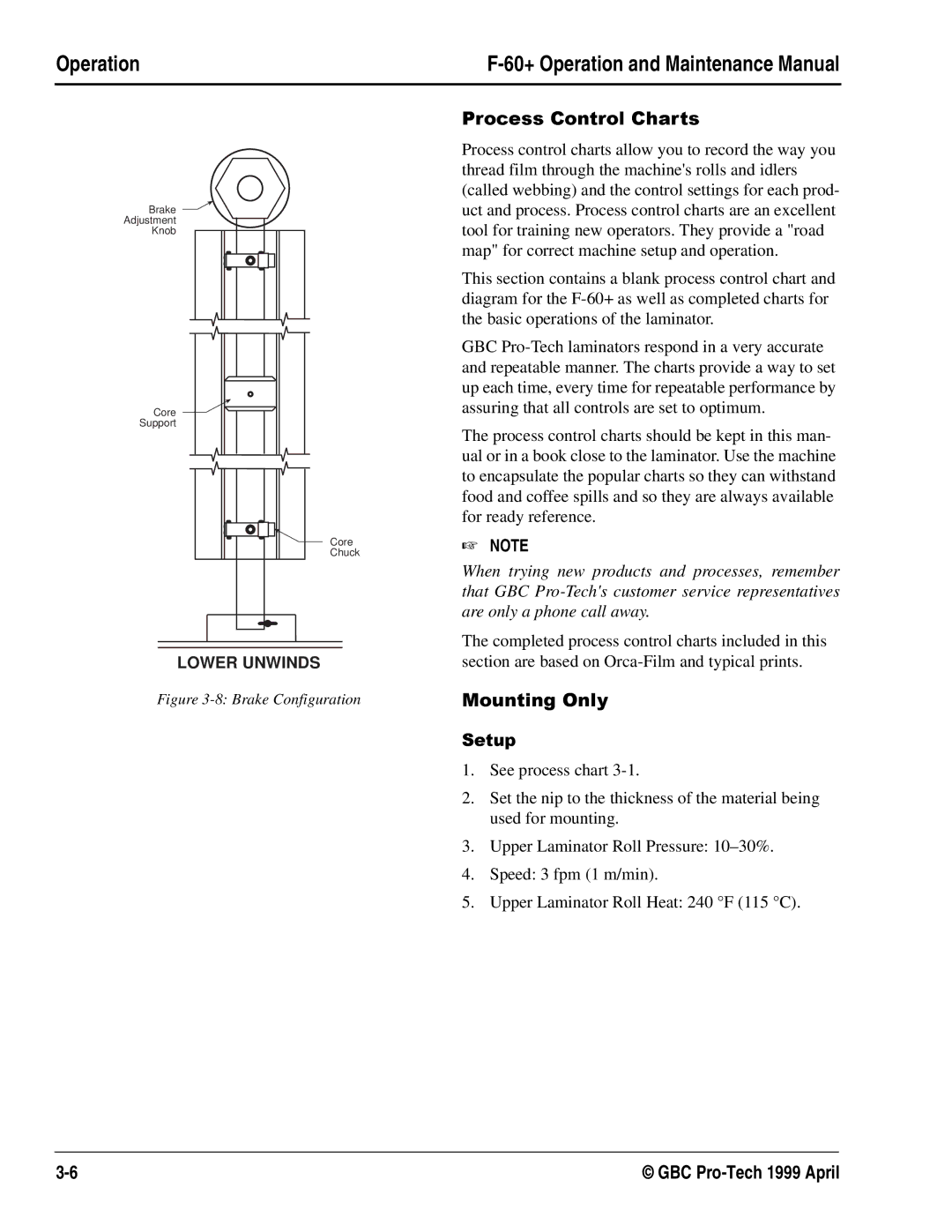

Brake

Adjustment

Knob

Core

Support

Core Chuck

Process control charts allow you to record the way you thread film through the machine's rolls and idlers (called webbing) and the control settings for each prod- uct and process. Process control charts are an excellent tool for training new operators. They provide a "road map" for correct machine setup and operation.

This section contains a blank process control chart and diagram for the

GBC

The process control charts should be kept in this man- ual or in a book close to the laminator. Use the machine to encapsulate the popular charts so they can withstand food and coffee spills and so they are always available for ready reference.

☞NOTE

LOWER UNWINDS

Figure 3-8: Brake Configuration

When trying new products and processes, remember that GBC

The completed process control charts included in this 6HW0RQWLQJ2QO\sectionXSare based on

1.See process chart 3-1.

2.Set the nip to the thickness of the material being used for mounting.

3.Upper Laminator Roll Pressure:

4.Speed: 3 fpm (1 m/min).

5.Upper Laminator Roll Heat: 240 °F (115 °C).

© GBC |