$GMXVWLQJWKH1LS | Maintenance and Troubleshooting |

|

The gap between two rolls is called the nip.

The purpose of adjusting the nip is to ensure continu- ous contact between the rolls as the media is drawn through the machine. This procedure must be done reg- ularly for the main rolls. It is not necessary to set the nip on the pull rolls.

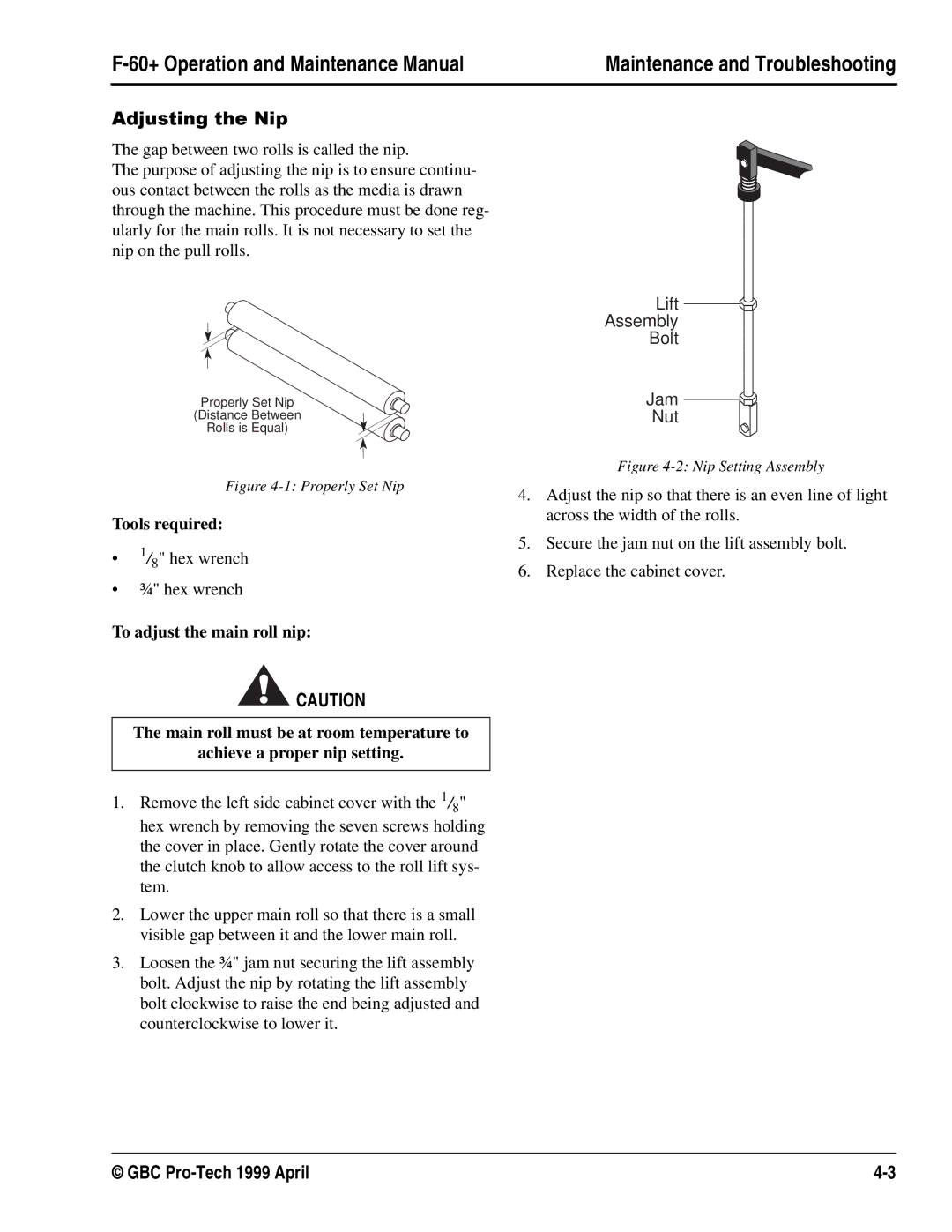

Lift

Assembly

Bolt

Properly Set Nip

(Distance Between

Rolls is Equal)

Figure 4-1: Properly Set Nip

Tools required:

•1/8" hex wrench

•¾" hex wrench

To adjust the main roll nip:

![]() CAUTION

CAUTION

The main roll must be at room temperature to

achieve a proper nip setting.

1.Remove the left side cabinet cover with the 1/8" hex wrench by removing the seven screws holding the cover in place. Gently rotate the cover around the clutch knob to allow access to the roll lift sys- tem.

2.Lower the upper main roll so that there is a small visible gap between it and the lower main roll.

3.Loosen the ¾" jam nut securing the lift assembly bolt. Adjust the nip by rotating the lift assembly bolt clockwise to raise the end being adjusted and counterclockwise to lower it.

Jam

Nut

Figure 4-2: Nip Setting Assembly

4.Adjust the nip so that there is an even line of light across the width of the rolls.

5.Secure the jam nut on the lift assembly bolt.

6.Replace the cabinet cover.

© GBC |