Important Safety Instructions

PR70e

Contents

Models

Related Manuals

Electric Shock Hazard

Fire and Explosion Hazard

Machine

Component Identification

IG Machine Key

Local Control Module LCM

AB System Shut-Down Key

LCM Screen Navigation

Screen Overview and Appendix C LCM Setup

Run Screen

Component Identification 334135B

Standard Dispense Valves, 255179

Recommended Parts

Dispense Valve

Gun Mounted MD2 Valves, LC0120 and LC0122

Lever Actuated MD2 Valves, LC0121 and LC0123

Part Description Quantity

Mixers

Shroud

Reference Number and Description

1301 1302 1303 Mixer

Package Description

Applicator Mounting

Part Description Mounting, valve, HMI Mounting, HMI

High Temperature Grease Footswitch

Air Filter and Ball Valve, 24R707

Tanks

Quantity Part Description 24W415 24W416 24W417

Hose Packages

Unheated, Non-Recirculating Hose

Recommended Parts 334135B

Piston Package

Nylon Piston, Stainless Steel Metering Tube Assemblies

Uhmw Piston, Stainless Steel Metering Tube Assemblies

Uhmw

Pump Tube Combination Information

Shot Size cc Air Motor In. Air Motor

Grounding

Installation

Machine Installation

General Grounding Guidelines

Install the Chemical Hoses

Install the Dispense Valve and Support Arm, if needed

Ground System

Electrical Requirements

Setup

Piston Position Calibration

Engaged Piston Position

Perform Pressure Relief Procedure on

Navigate to the Shot Mode Screen or Operator Mode Screen

Manually Move the Piston Drive Block

Prime the Dispense Head

Prime Dispense Head

Prepare the Machine

Phasing Adjustment

Adjust Dispense Quantity

Navigate to the Phasing Shot Calibration Screen

Adjust Phasing

Adjust Dispense Valve Snuff Back

Adjust Open Dispense Valve ODV Timing

Operator Mode Screen

Operation

Pressure Relief Procedure

Navigate to the Maintenance Mode Run Screen

Startup

Relieve pressure. See Pressure Relief Procedure,

Shutdown

Disassemble and Clean the Dispense Head

Maintenance

Clean the Pump Shafts

Schedule

Install Upgrade Token

Remove Access Panel

Troubleshooting

Problem Cause Solution

Problem Cause Solution

Code Name Type Causes Fixes Condition

LCM Error Codes

Trigger

Entries in Position Calibra

Prepare Machine for Kit Installation

HydraCheck Kit Installation, 24W336

Repair

Adjust the Adjustment Screw/Cap

Install Adjustment Screw/Cap

Adjust Shock Resistance

Air Cylinder Rebuild Instructions

Disassemble the Air Cylinder

Clean and Inspect the Parts

Re-Assemble the Air Cylinder

Rear Pump Rebuild Instructions

Assemble the Rear Pump Assembly

Prepare for Operation

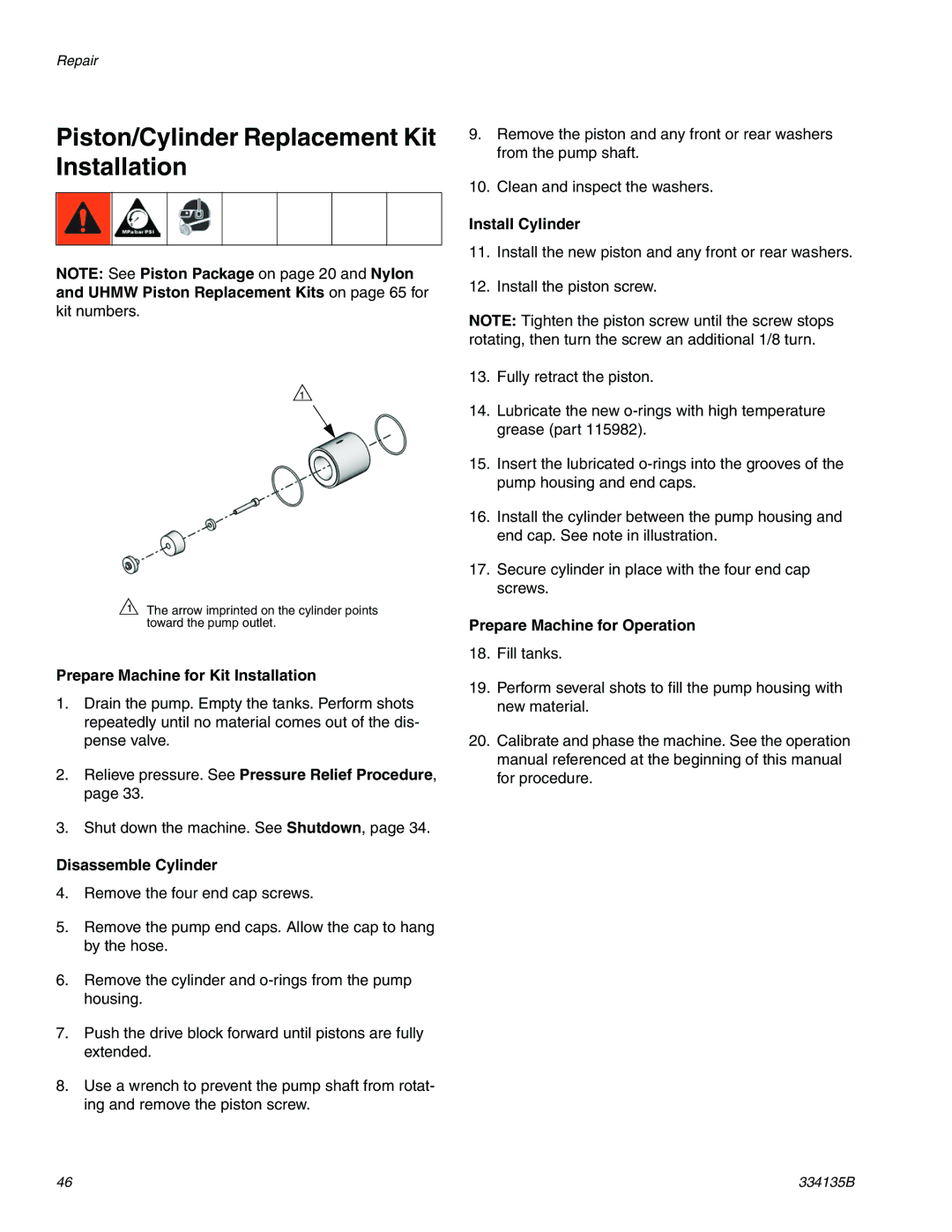

Install Cylinder

Piston/Cylinder Replacement Kit Installation

Disassemble Cylinder

Check Valve Rebuild Kit Installation

Parts

Fixed Ratio Base

24V935, Pump 24V936, Pump Part Description Assembly

Pump Sub-Assembly, 24S053

Check Valve, Assembly LC0093

Collar

Fixed Ratio Drive Block Assembly, LC0107

206 201 204 205 202 203

Air Cylinder, 24V933

24V933, Motor 24V934, Motor Part Description Air

Fixed Ratio Frame Sub-Assembly, LC0290

Uhmw Piston, Ceramic Metering Tube Assemblies

Ring, support Carbide Package Pump Piston Washer Screw Ball

Schematics

Electrical Schematics

Electrical Schematic

DB25 Pin Function

Pneumatic Schematic

DB25 Pin Number Pin Function Description

Schematics 334135B

Appendix a LCM Icon Overview

Adjust

Phasing Shot Adjust

Position Adjust

Amount Adjust

Shot Mode Screen

Splash Screen Operator Mode Screen

Disable Mode Screen

Mode Selection Programming Screen

Error Code Acknowledgement Screen

Maintenance Mode Run Screen

Shot Amount or Stroke % Adjust Screen

Run Screen while Dispensing

Setup Screen Password Set/Clear Screen

Appendix C LCM Setup Screen Overview

Phasing Shot Calibration Screen

LCF Piston Size mm2

Nylon and Uhmw Piston Replacement Kits

Kits

LCE Piston Size mm2

Recommended Spare Parts

MD2 Valve

Dimensions

Dimensions

Technical Data

Graco Standard Warranty

Graco Information

![]() 1 The arrow imprinted on the cylinder points toward the pump outlet.

1 The arrow imprinted on the cylinder points toward the pump outlet.