Sliding Table

Parallel Adjustment

Now is the point in the assembly process to make the sliding table parallel with the main saw blade and tighten the three large cap screws that were used to secure the sliding table to the saw base.

Besides the tools included with the saw, this pro- cedure requires you to have a precision ruler, a felt tip pen, and the assistance of another person.

To adjust the sliding table parallel with the main blade:

1.Set the blade to 0˚ on the control panel (90˚ with the cast iron table).

2.Raise the main blade up as far as it will go.

3.Disconnect the saw from the power source!

4.Mark the center of the blade with a felt tip pen. This will allow you to take your mea- surements from the exact same place on the blade.

5.Move the sliding table all the way to one end, and using a precision ruler, measure the gap between the edge of the table and your mark on the blade as shown in Figure 54.

Figure 54. Measuring gap between sliding table edge and center of blade with a precision ruler.

6.Move the other end of the sliding table in front of the blade and measure the gap.

—If the gap is the same on both sides, then the sliding table is already parallel with the main blade. Skip to step 10.

—If the gap on one side is different than the other, then continue with step 7.

7.Move the end of the sliding table that needs to be adjusted in front of the blade.

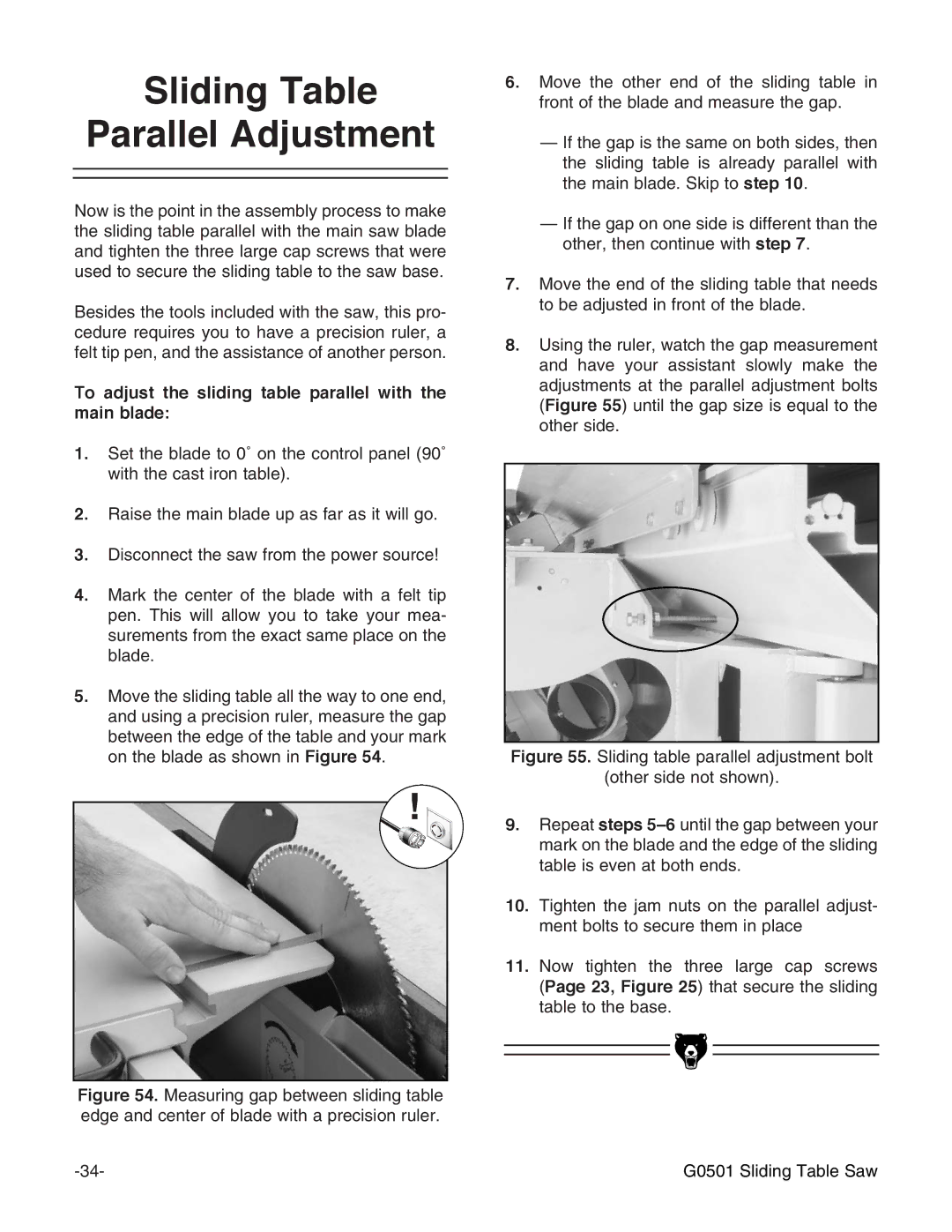

8.Using the ruler, watch the gap measurement and have your assistant slowly make the adjustments at the parallel adjustment bolts (Figure 55) until the gap size is equal to the other side.

Figure 55. Sliding table parallel adjustment bolt

(other side not shown).

9.Repeat steps 5–6 until the gap between your mark on the blade and the edge of the sliding table is even at both ends.

10.Tighten the jam nuts on the parallel adjust- ment bolts to secure them in place

11.Now tighten the three large cap screws (Page 23, Figure 25) that secure the sliding table to the base.

G0501 Sliding Table Saw |