SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Clean unpainted cast iron parts of jointer and planer tables

•Lubricate feed rollers

Weekly Check:

•Clean cutterhead

Monthly Check:

•Inspect

•Clean/vacuum dust buildup from inside cabi- net and off motor

•Lubricate worm gear

•Lubricate roller chains

•Lubricate elevation lead screw

•Lubricate worm shaft

Cleaning

Vacuum excess wood chips and sawdust, and wipe off the remaining dust with a dry

V-Belts

Always replace

Consider replacing stock belts with Power Twist

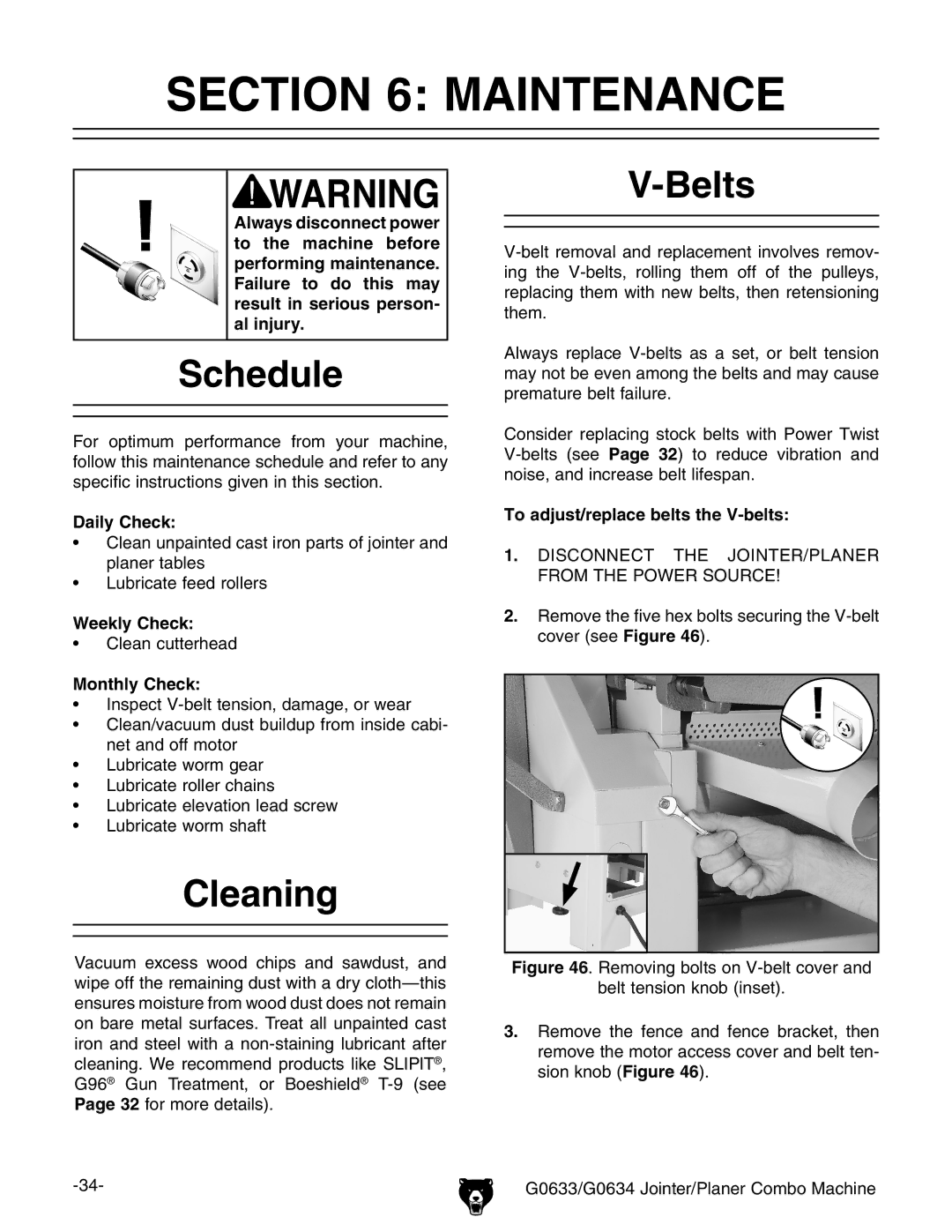

To adjust/replace belts the V-belts:

1.DISCONNECT THE JOINTER/PLANER FROM THE POWER SOURCE!

2.Remove the five hex bolts securing the