Calibrating Depth

Scale

The depth scale on the infeed table can be cali- brated or "zeroed" if it is not correct.

Tools Needed | Qty |

Straightedge | 1 |

Phillips Screwdriver | 1 |

To calibrate the depth scale: |

|

1.DISCONNECT THE JOINTER/PLANER FROM THE POWER SOURCE!

2.Set the outfeed table height as described in the Setting Outfeed Table Height instruc- tions on Page 18.

3.Use the straightedge to help adjust the infeed table exactly even with the outfeed table, as shown in Figure 65.

������������ ������� ![]()

![]() ������

������

Figure 65. Infeed table even with outfeed table.

4. Using a screwdriver, adjust the scale pointer to zero (Figure 66).

Figure 66. Depth scale adjusted to “0” position.

Pulley Alignment

Tools Needed: | Qty |

Straightedge | 1 |

Hex Wrench 3mm | 1 |

2 | |

Proper pulley alignment (see Figure 68) prevents | |

premature belt wear. The pulleys are properly | |

aligned when they are parallel and in the same | |

plane as each other. |

|

To align the pulleys: |

|

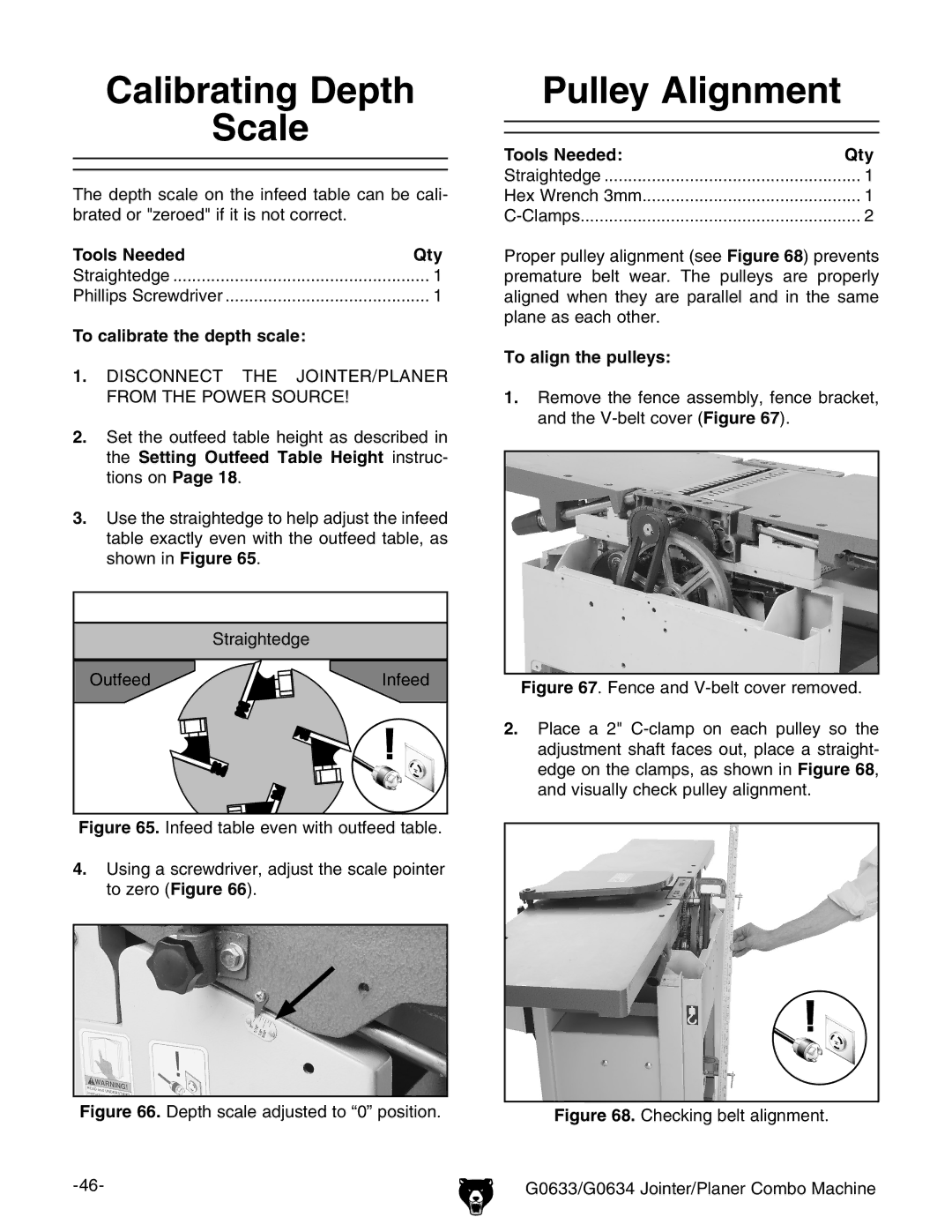

1.Remove the fence assembly, fence bracket, and the

Figure 67. Fence and V-belt cover removed.

2.Place a 2" C-clamp on each pulley so the adjustment shaft faces out, place a straight- edge on the clamps, as shown in Figure 68, and visually check pulley alignment.

Figure 68. Checking belt alignment.

G0633/G0634 Jointer/Planer Combo Machine |