| 12" Min. |

| 12" Min. |

|

|

| |

1" Min. |

| 1 | ⁄2" Min. |

|

|

| |

1 | ⁄2" Min. |

| 1" Min. |

|

|

|

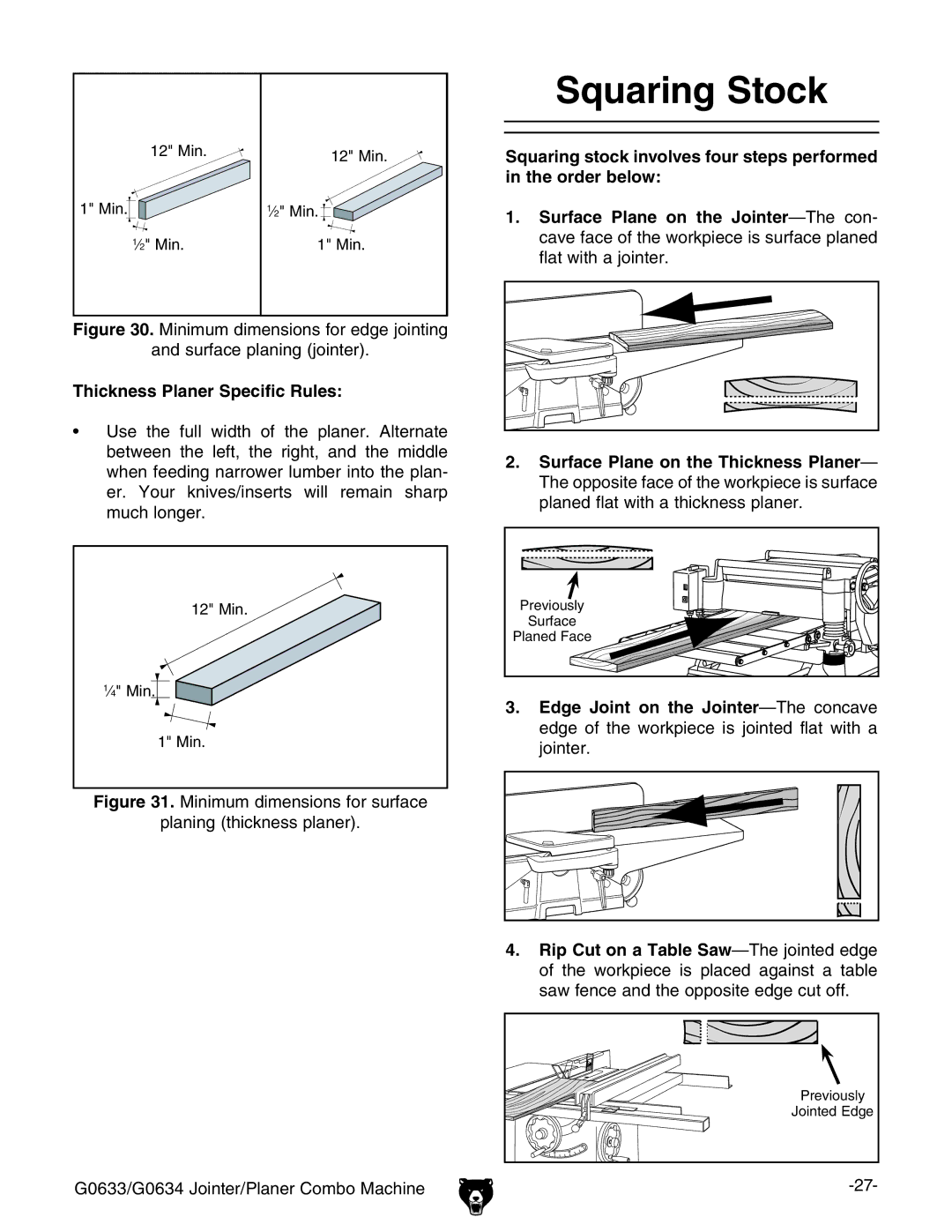

Figure 30. Minimum dimensions for edge jointing and surface planing (jointer).

Thickness Planer Specific Rules:

•Use the full width of the planer. Alternate between the left, the right, and the middle when feeding narrower lumber into the plan- er. Your knives/inserts will remain sharp much longer.

12" Min.

1 | ⁄4" Min. |

| |

| 1" Min. |

Figure 31. Minimum dimensions for surface | |

| planing (thickness planer). |

Squaring Stock

Squaring stock involves four steps performed in the order below:

1.Surface Plane on the

2.Surface Plane on the Thickness Planer— The opposite face of the workpiece is surface planed flat with a thickness planer.

Previously

Surface

Planed Face

3.Edge Joint on the

4.Rip Cut on a Table

saw fence and the opposite edge cut off.

Previously

Jointed Edge

��

�� | �� |

G0633/G0634 Jointer/Planer Combo Machine |