Inspecting Knives

(G0633 Only)

Tools Needed: | Qty |

Knife Setting Gauge | .......................................... 1 |

Straightedge | 1 |

The height of the knives can be inspected with the knife setting jig or with a straightedge.

Inspecting the height of the knives with a straight- edge ensures that they are set evenly with the outfeed table at their highest point in the cutterhead rotation.

To inspect the knives with the knife setting gauge:

1.DISCONNECT THE JOINTER/PLANER FROM THE POWER SOURCE!

2.Remove the cutterhead guard.

3.Raise both tables out of the way.

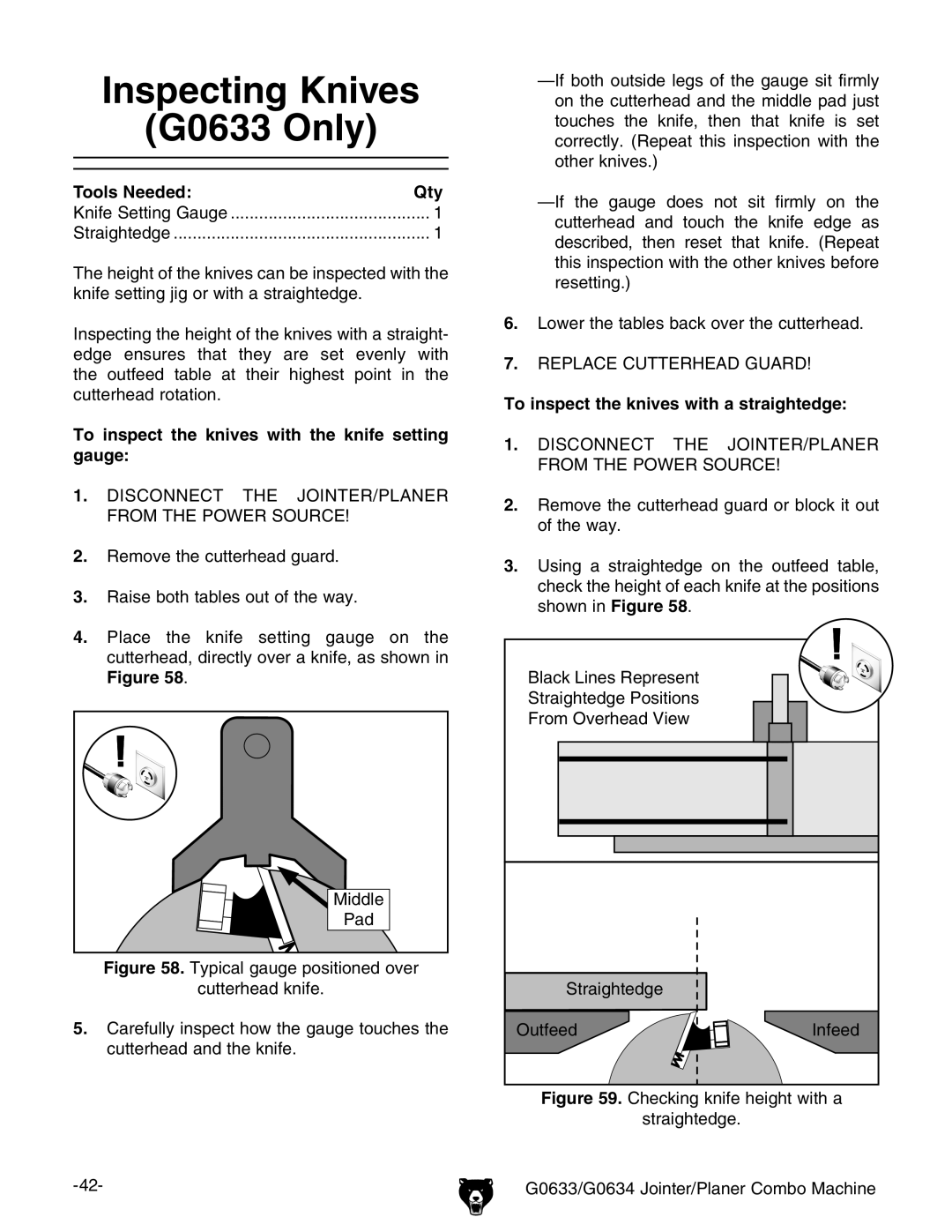

4.Place the knife setting gauge on the cutterhead, directly over a knife, as shown in Figure 58.

Middle

Pad

Figure 58. Typical gauge positioned over

cutterhead knife.

5.Carefully inspect how the gauge touches the cutterhead and the knife.

—If both outside legs of the gauge sit firmly on the cutterhead and the middle pad just touches the knife, then that knife is set correctly. (Repeat this inspection with the other knives.)

—If the gauge does not sit firmly on the cutterhead and touch the knife edge as described, then reset that knife. (Repeat this inspection with the other knives before resetting.)

6.Lower the tables back over the cutterhead.

7.REPLACE CUTTERHEAD GUARD!

To inspect the knives with a straightedge:

1.DISCONNECT THE JOINTER/PLANER FROM THE POWER SOURCE!

2.Remove the cutterhead guard or block it out of the way.

3.Using a straightedge on the outfeed table, check the height of each knife at the positions shown in Figure 58.

���������������������

����������������������

������������������

������������

�������![]()

![]() ������

������