2.Adjust the tension screws counterclockwise so that they are five to seven turns below the top of the head casting.

Anti-Kickback Fingers

The Model G6333/G0634 provides an

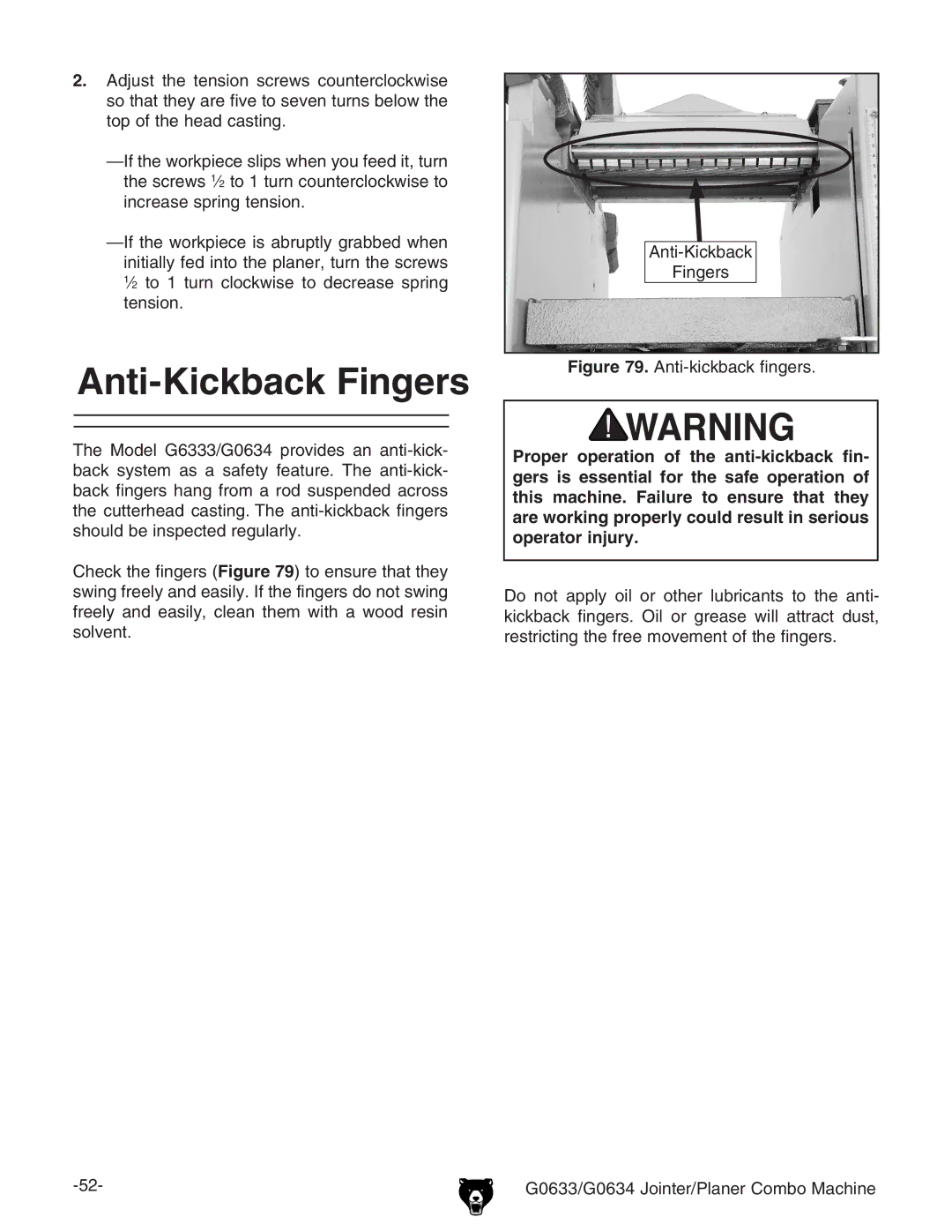

Check the fingers (Figure 79) to ensure that they swing freely and easily. If the fingers do not swing freely and easily, clean them with a wood resin solvent.

Figure 79. Anti-kickback fingers.

Proper operation of the

Do not apply oil or other lubricants to the anti- kickback fingers. Oil or grease will attract dust, restricting the free movement of the fingers.

G0633/G0634 Jointer/Planer Combo Machine |