Checking/Adjusting

Jointer Table

Parallelism

The outfeed table is preset by the factory parallel with the cutterhead. However, it is critical to check this setting. If the tables are not parallel with the cutterhead or each other, then poor cutting results and kickback can occur.

Tools Needed | Qty |

Straightedge | 1 |

Adjustable Wrench | 1 |

Checking Outfeed Table Parallelism

1.DISCONNECT THE JOINTER/PLANER FROM THE POWER SOURCE!

2.Put on leather gloves, then remove the cutterhead guard and fence.

3.Place the straightedge on the outfeed table so it hangs over the cutterhead in one of the positions shown in Figure 52.

���������������������

����������������������

������������������

Figure 52. Straightedge positions for verifying if

outfeed table is parallel with cutterhead.

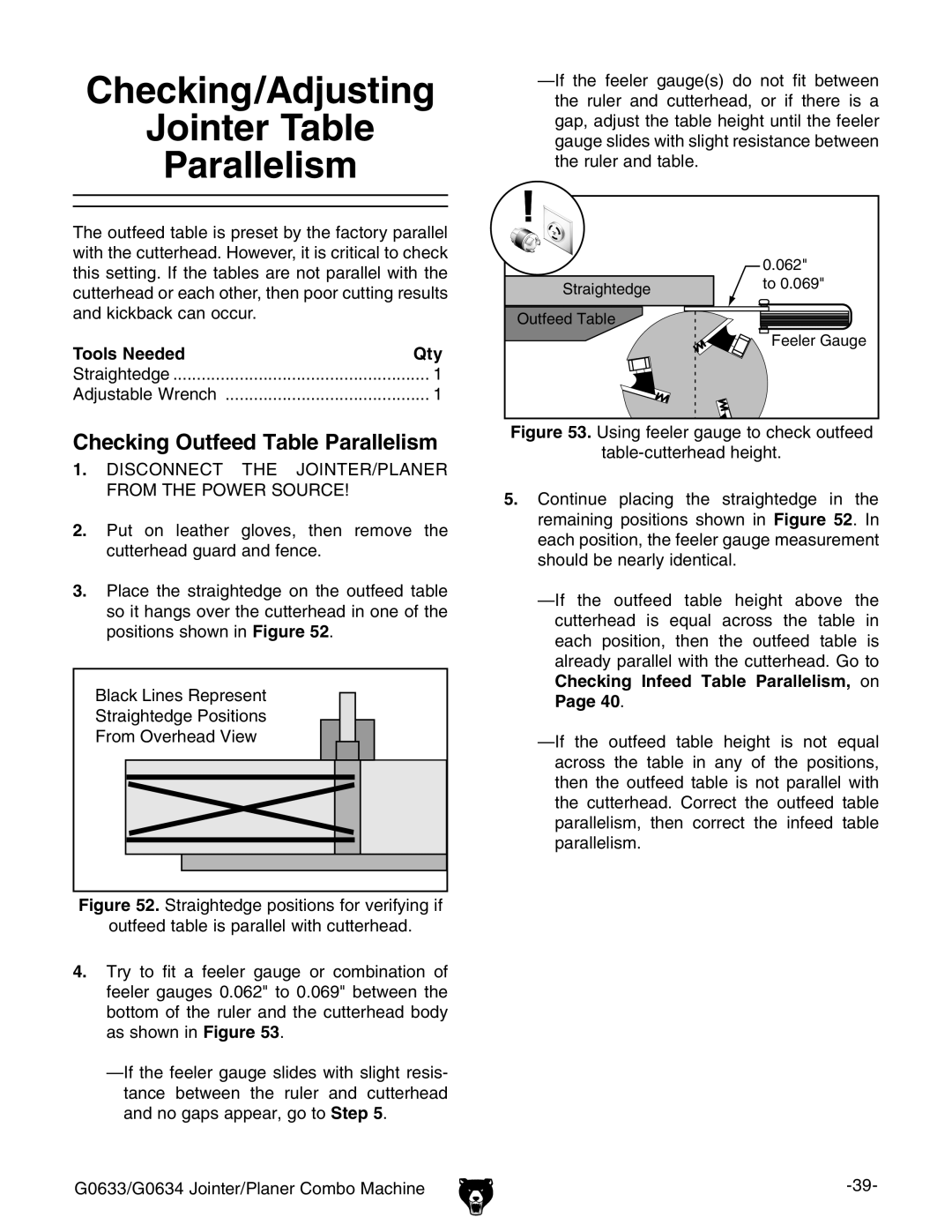

4.Try to fit a feeler gauge or combination of feeler gauges 0.062" to 0.069" between the bottom of the ruler and the cutterhead body as shown in Figure 53.

—If the feeler gauge slides with slight resis- tance between the ruler and cutterhead and no gaps appear, go to Step 5.

—If the feeler gauge(s) do not fit between the ruler and cutterhead, or if there is a gap, adjust the table height until the feeler gauge slides with slight resistance between the ruler and table.

������

����������������������

�������������

������������

Figure 53. Using feeler gauge to check outfeed

table-cutterhead height.

5.Continue placing the straightedge in the remaining positions shown in Figure 52. In each position, the feeler gauge measurement should be nearly identical.

—If the outfeed table height above the cutterhead is equal across the table in each position, then the outfeed table is already parallel with the cutterhead. Go to Checking Infeed Table Parallelism, on Page 40.

—If the outfeed table height is not equal across the table in any of the positions, then the outfeed table is not parallel with the cutterhead. Correct the outfeed table parallelism, then correct the infeed table parallelism.

G0633/G0634 Jointer/Planer Combo Machine |