Adjusting/Replacing

Knives (G0633)

Tools Needed: | Qty |

Straightedge | 1 |

Hex Wrench 3mm | 1 |

Wrench 8mm | 1 |

Setting the knives correctly is crucial to the proper operation of the jointer and is very important in keeping the knives sharp. If one knife is higher than the others, it will do the majority of the work, and thus, dull much faster than the others.

There are two options for setting the

Straightedge Method: A high quality straightedge is held flat against the outfeed table and the knife heights are set to the bottom of the straightedge, as shown in Figure 59. Because the knife projec- tion height from the cutterhead is dependent on the outfeed table height, the outfeed table must be parallel to the cutterhead (Page 39) and set as described in Setting Outfeed Table Height on Page 18 for this method to work correctly.

Knife Setting Jig Method: Both tables are flipped up to fit the gauge on the cutterhead, as shown in Figure 60, and the knife heights are set to just touch the middle pad of the gauge.

The knife setting gauge makes it easy to ensure that the knives project out of the cutterhead evenly. After using the knife setting gauge to set the knives, you have to

The included knife gauge is designed to set the knives approximately 0.062" higher than the cutterhead.

Figure 60. Using knife setting gauge to set knife

height.

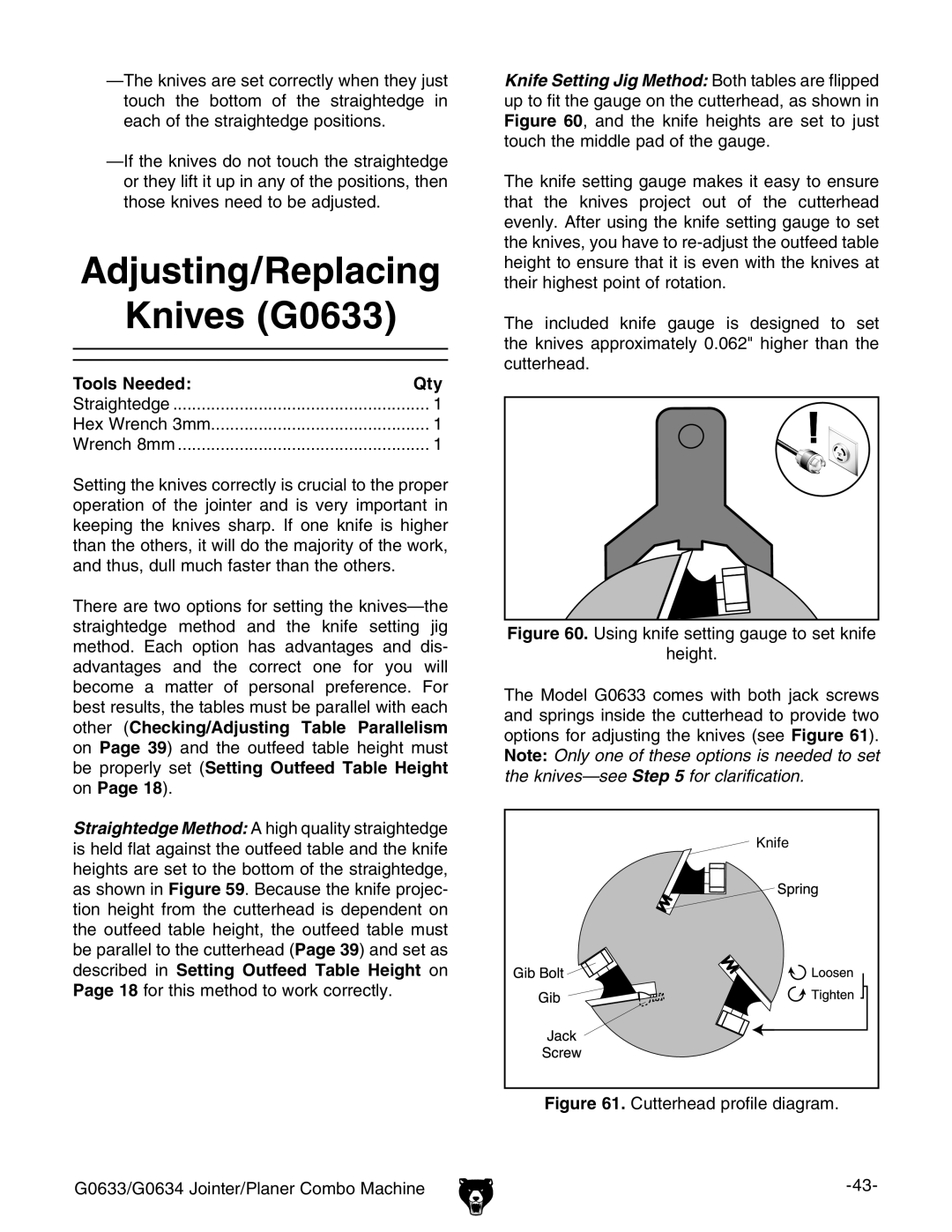

The Model G0633 comes with both jack screws and springs inside the cutterhead to provide two options for adjusting the knives (see Figure 61). Note: Only one of these options is needed to set the knives—see Step 5 for clarification.

�����

Figure 61. Cutterhead profile diagram.

G0633/G0634 Jointer/Planer Combo Machine |