H E AT C O N T R O L L E R , I N C . WAT E R - S O U R C E H E AT P U M P S

R e s i d e n t i a l S p l i t - 6 0 H z R 2 2 & R 4 1 0 A

R e v. : 5 J u n e , 2 0 0 8

Hot Water Generator

The HWG (Hot Water Generator) or desuperheater option provides considerable operating cost savings by utilizing excess heat energy from the heat pump to help satisfy domestic hot water requirements. The HWG

is active throughout the year, providing virtually free hot water when the heat pump operates in the cooling mode or hot water at the COP of the heat pump during operation in the heating mode. Actual HWG water heating capacities are provided in the appropriate heat pump performance data.

Heat pumps equipped with the HWG option include a

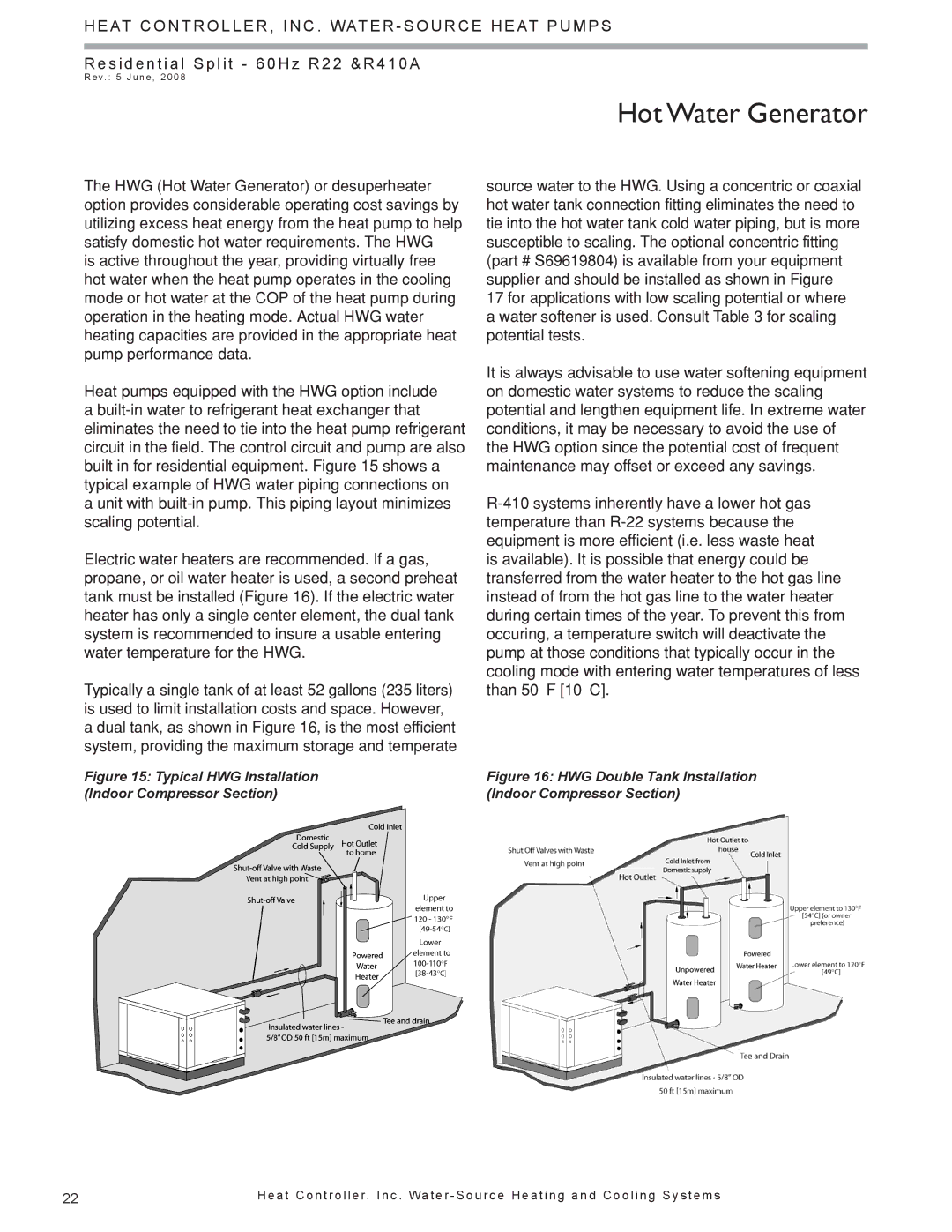

Electric water heaters are recommended. If a gas, propane, or oil water heater is used, a second preheat tank must be installed (Figure 16). If the electric water heater has only a single center element, the dual tank system is recommended to insure a usable entering water temperature for the HWG.

Typically a single tank of at least 52 gallons (235 liters) is used to limit installation costs and space. However, a dual tank, as shown in Figure 16, is the most efficient system, providing the maximum storage and temperate

Figure 15: Typical HWG Installation

(Indoor Compressor Section)

source water to the HWG. Using a concentric or coaxial hot water tank connection fitting eliminates the need to tie into the hot water tank cold water piping, but is more susceptible to scaling. The optional concentric fitting (part # S69619804) is available from your equipment supplier and should be installed as shown in Figure

17 for applications with low scaling potential or where a water softener is used. Consult Table 3 for scaling potential tests.

It is always advisable to use water softening equipment on domestic water systems to reduce the scaling potential and lengthen equipment life. In extreme water conditions, it may be necessary to avoid the use of the HWG option since the potential cost of frequent maintenance may offset or exceed any savings.

Figure 16: HWG Double Tank Installation (Indoor Compressor Section)

22 | H e a t C o n t r o l l e r, I n c . Wa t e r - S o u r c e H e a t i n g a n d C o o l i n g S y s t e m s |