T h e Q u a l i t y L e a d e r i n C o n d i t i o n i n g A i r

R e s i d e n t i a l S p l i t - 6 0 H z R 2 2 & R 4 1 0 A

R e v. : 5 J u n e , 2 0 0 8

Refrigeration Installation

x CAUTION! x

CAUTION!

x CAUTION! x

CAUTION! Installation of a factory supplied liquid line

Line Set Installation

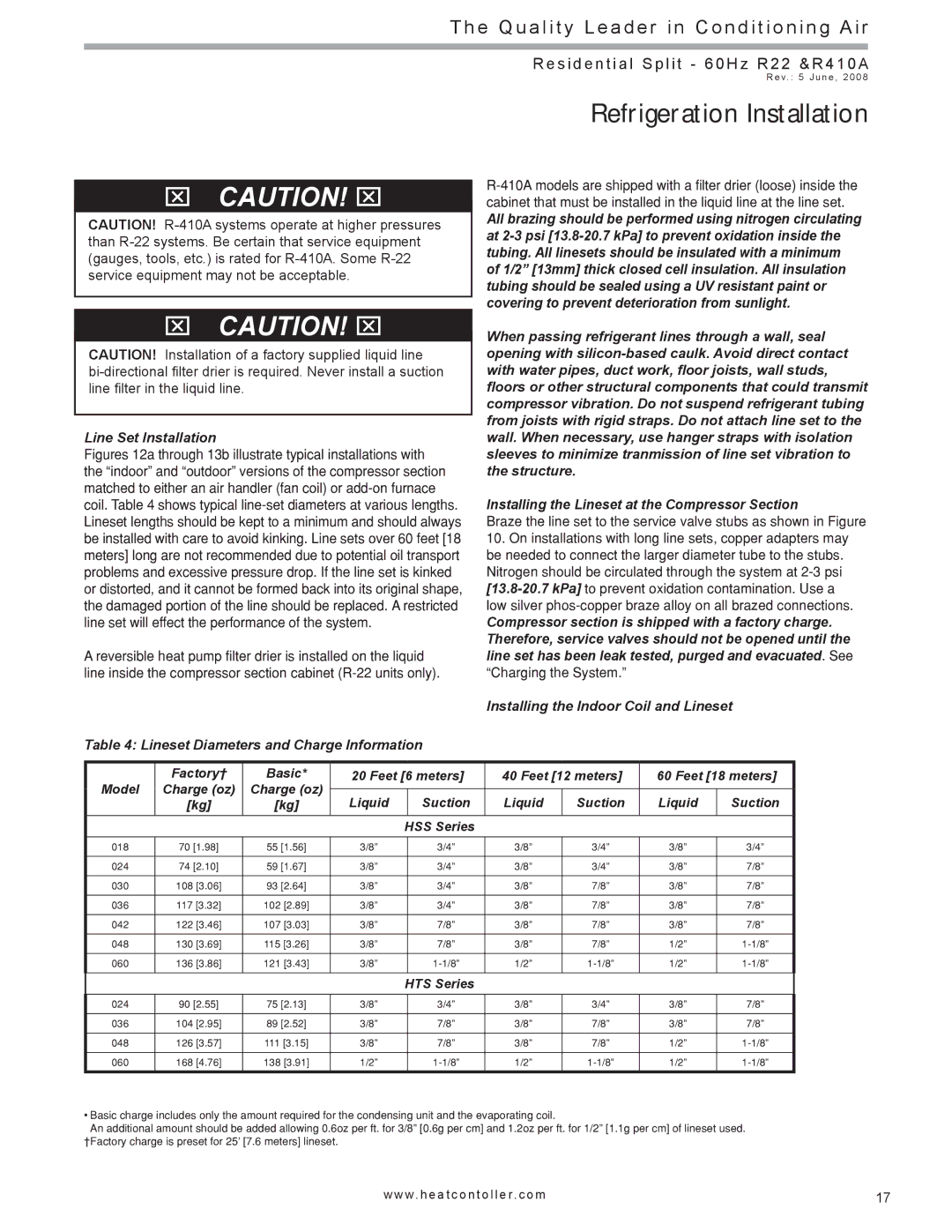

Figures 12a through 13b illustrate typical installations with the “indoor” and “outdoor” versions of the compressor section matched to either an air handler (fan coil) or add-on furnace coil. Table 4 shows typical line-set diameters at various lengths. Lineset lengths should be kept to a minimum and should always be installed with care to avoid kinking. Line sets over 60 feet [18 meters] long are not recommended due to potential oil transport problems and excessive pressure drop. If the line set is kinked or distorted, and it cannot be formed back into its original shape, the damaged portion of the line should be replaced. A restricted line set will effect the performance of the system.

A reversible heat pump filter drier is installed on the liquid line inside the compressor section cabinet (R-22 units only).

Table 4: Lineset Diameters and Charge Information

All brazing should be performed using nitrogen circulating at

When passing refrigerant lines through a wall, seal opening with

Installing the Lineset at the Compressor Section

Braze the line set to the service valve stubs as shown in Figure

10.On installations with long line sets, copper adapters may be needed to connect the larger diameter tube to the stubs. Nitrogen should be circulated through the system at

Compressor section is shipped with a factory charge. Therefore, service valves should not be opened until the line set has been leak tested, purged and evacuated. See “Charging the System.”

Installing the Indoor Coil and Lineset

| Factory† | Basic* | 20 Feet [6 meters] | 40 Feet [12 meters] | 60 Feet [18 meters] | ||||

Model | Charge (oz) | Charge (oz) |

|

|

|

|

|

|

|

Liquid |

| Suction | Liquid | Suction | Liquid | Suction | |||

| [kg] | [kg] |

| ||||||

|

|

|

| HSS Series |

|

|

|

| |

018 | 70 [1.98] | 55 [1.56] | 3/8” |

| 3/4” | 3/8” | 3/4” | 3/8” | 3/4” |

|

|

|

|

|

|

|

|

|

|

024 | 74 [2.10] | 59 [1.67] | 3/8” |

| 3/4” | 3/8” | 3/4” | 3/8” | 7/8” |

|

|

|

|

|

|

|

|

|

|

030 | 108 [3.06] | 93 [2.64] | 3/8” |

| 3/4” | 3/8” | 7/8” | 3/8” | 7/8” |

|

|

|

|

|

|

|

|

|

|

036 | 117 [3.32] | 102 [2.89] | 3/8” |

| 3/4” | 3/8” | 7/8” | 3/8” | 7/8” |

|

|

|

|

|

|

|

|

|

|

042 | 122 [3.46] | 107 [3.03] | 3/8” |

| 7/8” | 3/8” | 7/8” | 3/8” | 7/8” |

|

|

|

|

|

|

|

|

|

|

048 | 130 [3.69] | 115 [3.26] | 3/8” |

| 7/8” | 3/8” | 7/8” | 1/2” | |

|

|

|

|

|

|

|

|

|

|

060 | 136 [3.86] | 121 [3.43] | 3/8” |

| 1/2” | 1/2” | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| HTS Series |

|

|

|

| |

024 | 90 [2.55] | 75 [2.13] | 3/8” |

| 3/4” | 3/8” | 3/4” | 3/8” | 7/8” |

|

|

|

|

|

|

|

|

|

|

036 | 104 [2.95] | 89 [2.52] | 3/8” |

| 7/8” | 3/8” | 7/8” | 3/8” | 7/8” |

|

|

|

|

|

|

|

|

|

|

048 | 126 [3.57] | 111 [3.15] | 3/8” |

| 7/8” | 3/8” | 7/8” | 1/2” | |

|

|

|

|

|

|

|

|

|

|

060 | 168 [4.76] | 138 [3.91] | 1/2” |

| 1/2” | 1/2” | |||

•Basic charge includes only the amount required for the condensing unit and the evaporating coil.

An additional amount should be added allowing 0.6oz per ft. for 3/8” [0.6g per cm] and 1.2oz per ft. for 1/2” [1.1g per cm] of lineset used.

†Factory charge is preset for 25’ [7.6 meters] lineset.

w w w. h e a t c o n t o l l e r. c o m | 17 |