H E AT C O N T R O L L E R , I N C . WAT E R - S O U R C E H E AT P U M P S

R e s i d e n t i a l S p l i t - 6 0 H z R 2 2 & R 4 1 0 A

R e v. : 5 J u n e , 2 0 0 8

Equipment Selection

Air Handler Selection Example

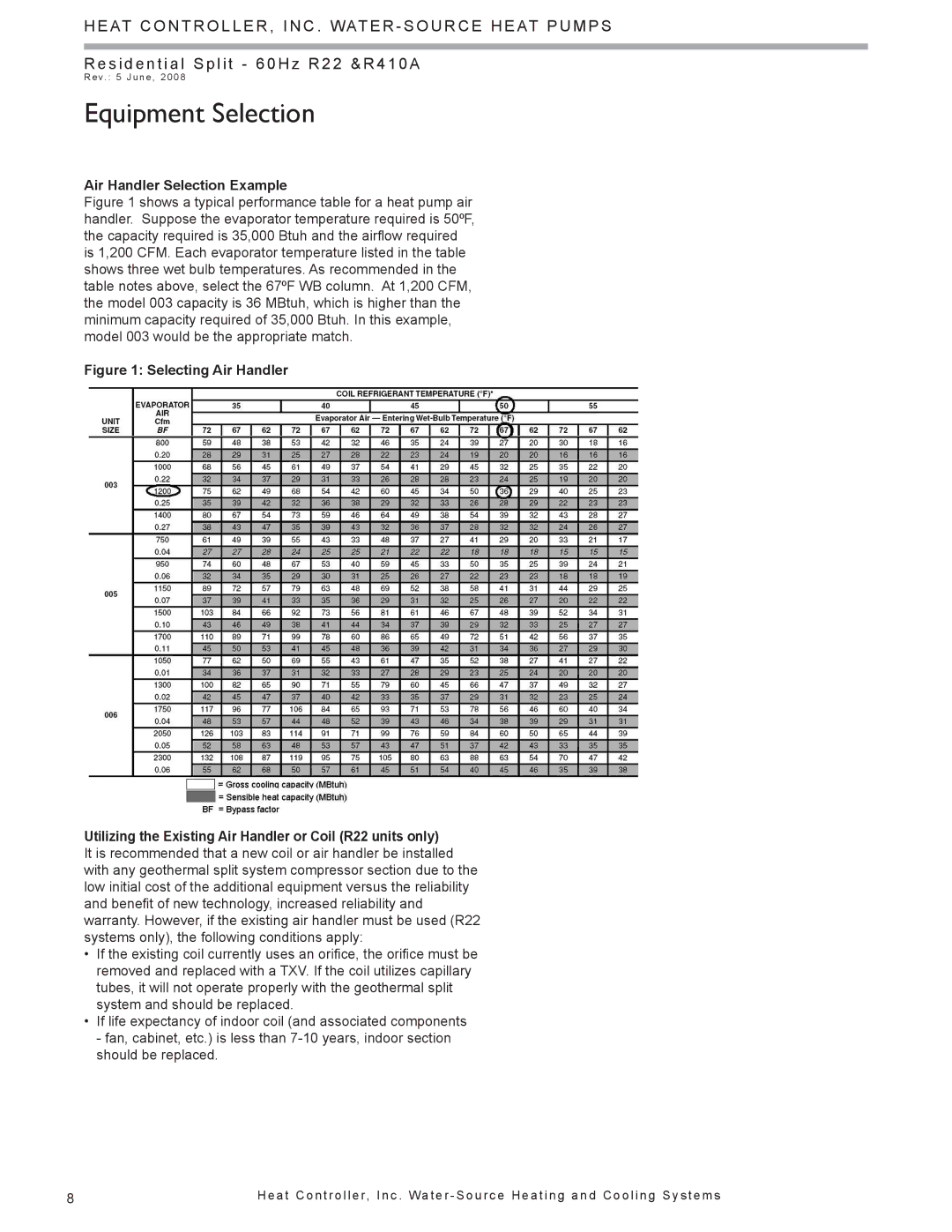

Figure 1 shows a typical performance table for a heat pump air handler. Suppose the evaporator temperature required is 50ºF, the capacity required is 35,000 Btuh and the airflow required is 1,200 CFM. Each evaporator temperature listed in the table shows three wet bulb temperatures. As recommended in the table notes above, select the 67ºF WB column. At 1,200 CFM, the model 003 capacity is 36 MBtuh, which is higher than the minimum capacity required of 35,000 Btuh. In this example, model 003 would be the appropriate match.

Figure 1: Selecting Air Handler

Utilizing the Existing Air Handler or Coil (R22 units only) It is recommended that a new coil or air handler be installed with any geothermal split system compressor section due to the low initial cost of the additional equipment versus the reliability and benefit of new technology, increased reliability and warranty. However, if the existing air handler must be used (R22 systems only), the following conditions apply:

•If the existing coil currently uses an orifice, the orifice must be removed and replaced with a TXV. If the coil utilizes capillary tubes, it will not operate properly with the geothermal split system and should be replaced.

•If life expectancy of indoor coil (and associated components - fan, cabinet, etc.) is less than

8 | H e a t C o n t r o l l e r, I n c . Wa t e r - S o u r c e H e a t i n g a n d C o o l i n g S y s t e m s |